Construction method facilitating guarantee of hollow floor structural size

A technology of structural size and construction method, applied in building structure, processing of building materials, construction, etc., can solve problems such as large deviation between structural size and design, occupancy box or steel bar tilting, affecting building manufacturing quality, etc. Achieve the effects of improving manufacturing quality, increasing material costs, and making connection and construction operations simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

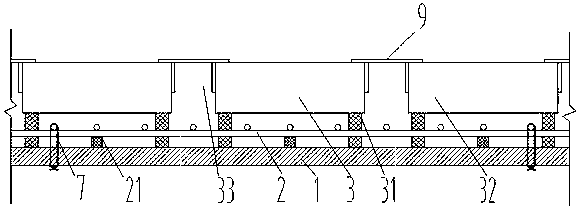

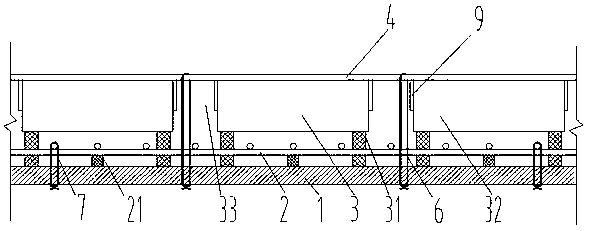

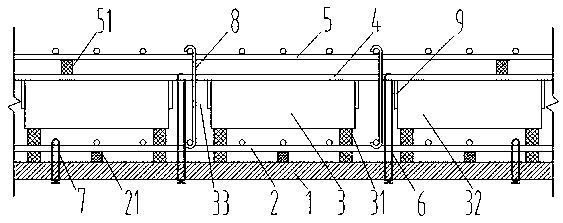

[0049] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0050] see Figure 1-5 , the specific embodiment of the present invention is beneficial to the construction method that guarantees the structural size of the hollow floor slab, comprising the following steps:

[0051] S1, laying horizontal bottom formwork 1 and side forms (not shown in the figure);

[0052] S2, place some bottom reinforcement pads 21 on the bottom template 1 according to the design position, and then lay the bottom reinforcement layer 2; the bottom reinforcement layer 2 is jointly supported by all bottom reinforcement pads 21;

[0053] S3. Use several second connectors 7 to connect the bottom reinforcing bar layer 2 with the bottom template 1 to limit the upward movement of the bottom reinforcing bar layer 2; see figure 1 ;

[0054] S4. Place a number of occupancy box pads 31 on the bottom template 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com