Intake duct for internal combustion engine

A technology for intake pipes and internal combustion engines, which is applied in the field of intake pipes and can solve problems such as increased airflow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

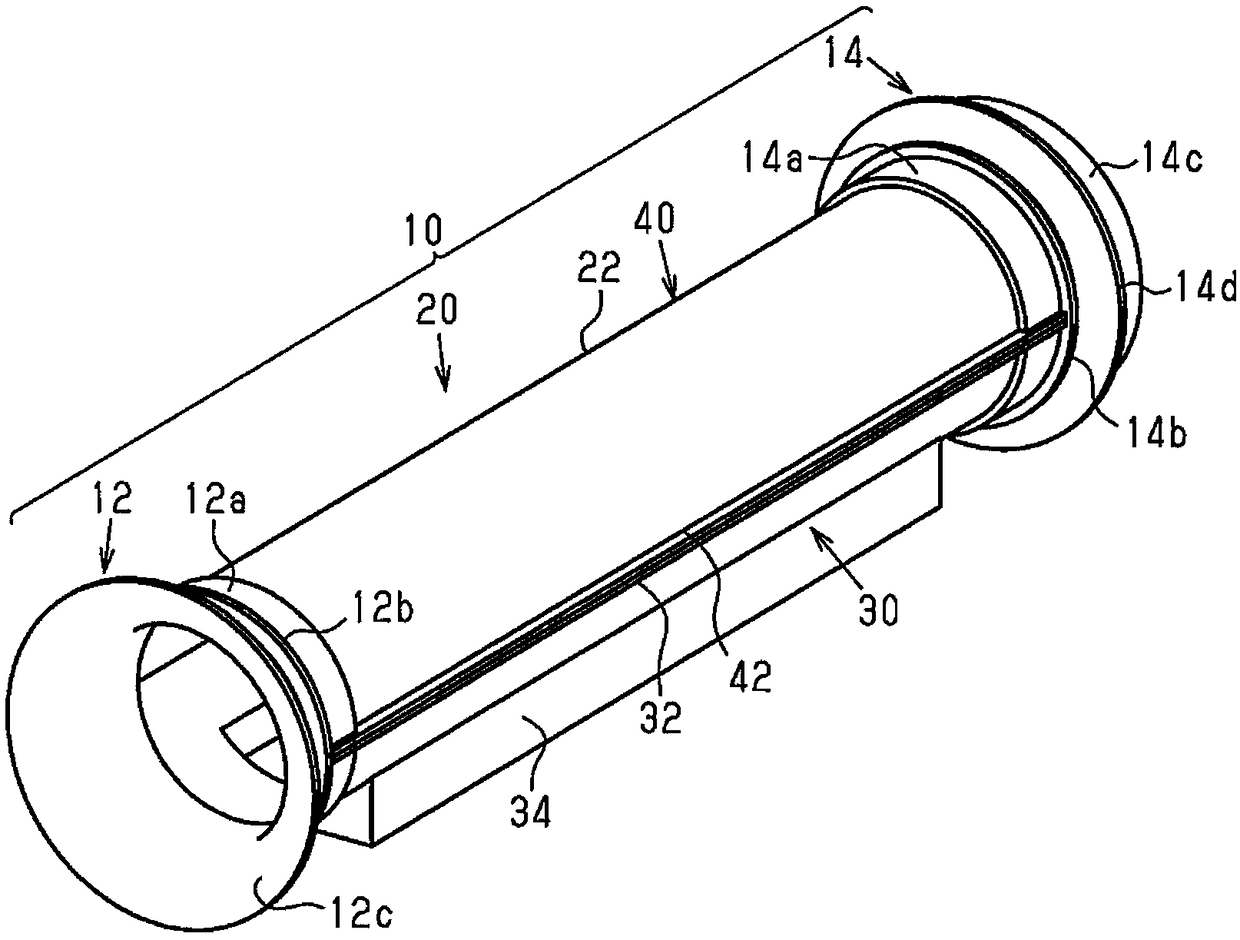

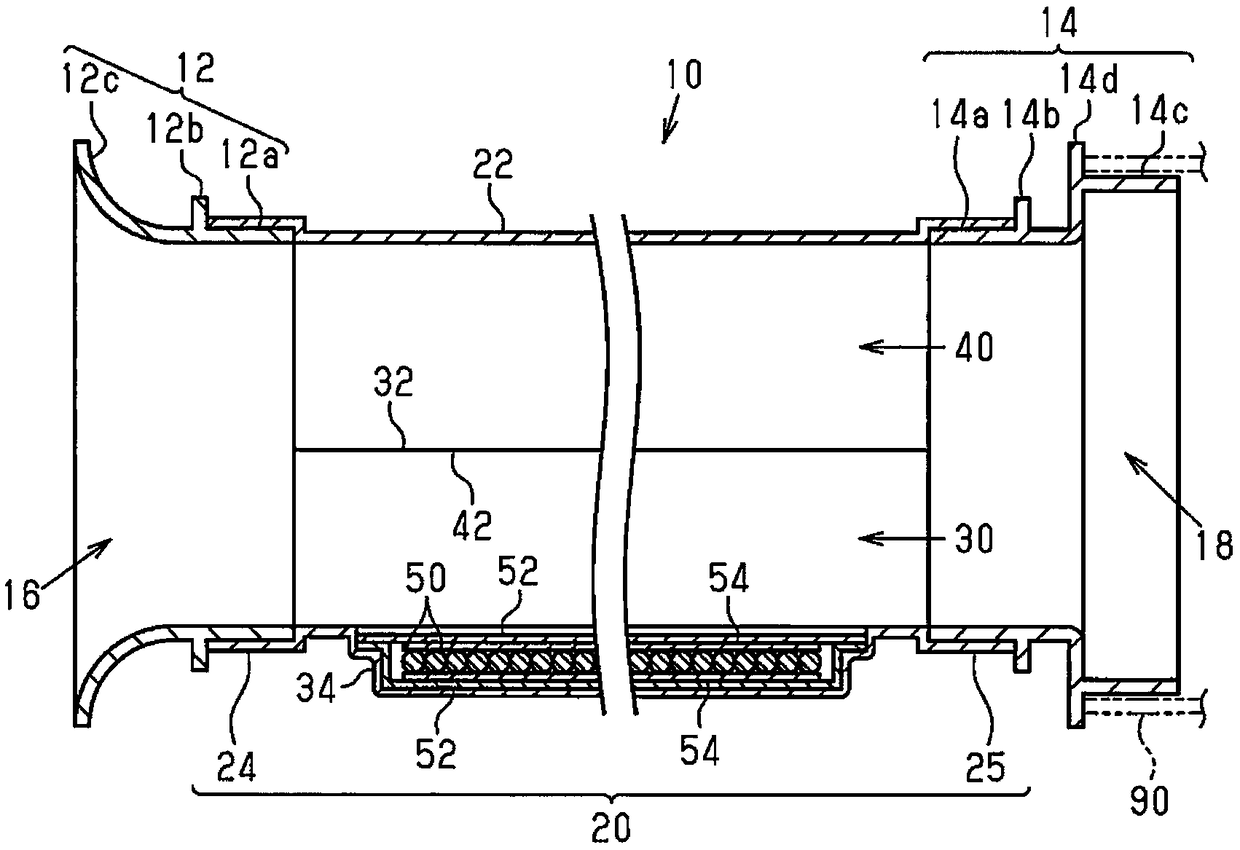

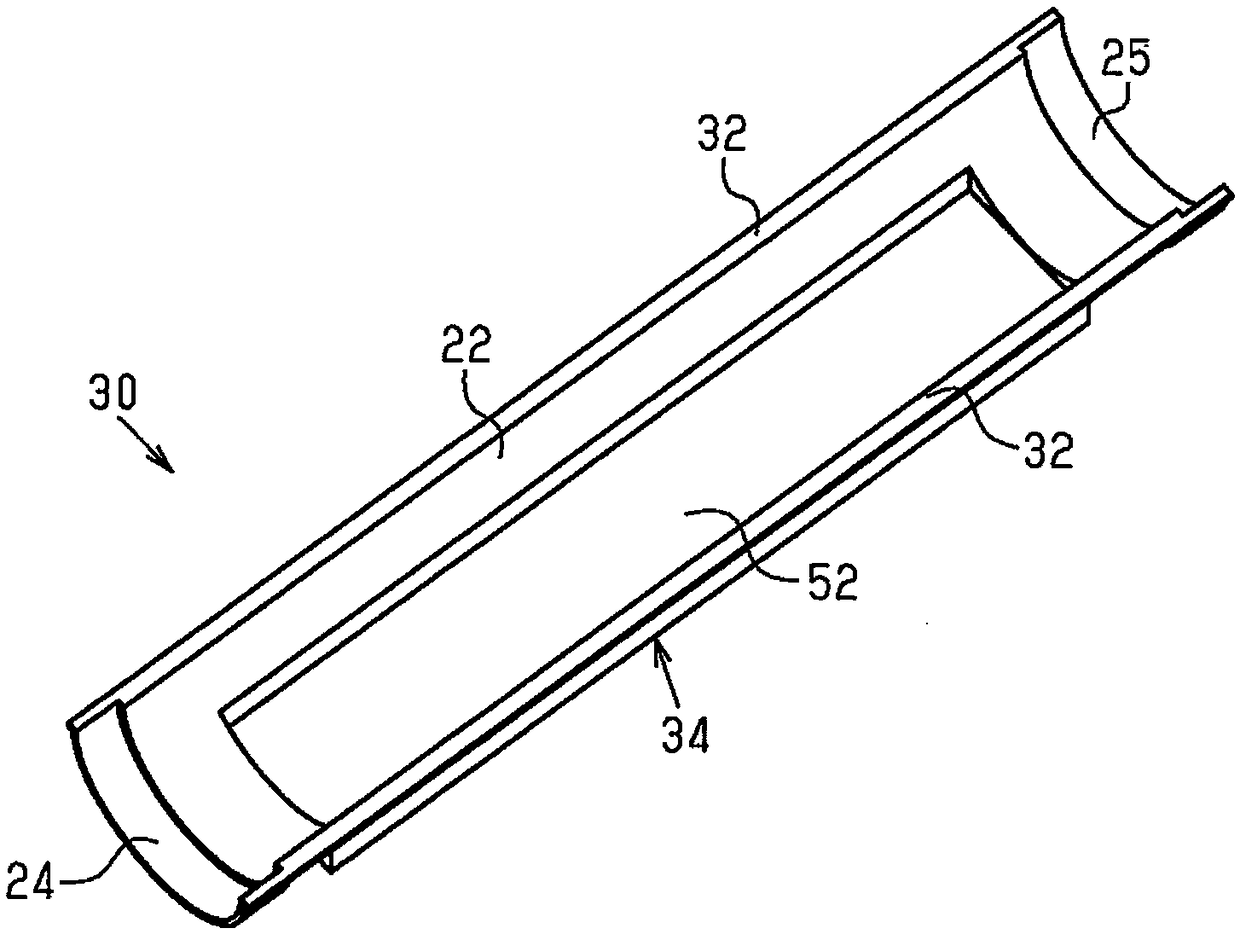

[0012] will now refer to Figure 1 to Figure 5 One embodiment will be described.

[0013] Such as figure 1 and figure 2 As shown, an intake pipe 10 for an internal combustion engine includes an upstream side connecting member 12 , a pipe main body 20 and a downstream side connecting member 14 . The intake pipe 10 is connected to the figure 2 The double-dashed line in represents the air intake 90 of the air filter and constitutes a part of the intake passage.

[0014] In the following description, the upstream side and the downstream side in the flow direction of the incoming air in the intake pipe 10 are simply referred to as the upstream side and the downstream side, respectively.

[0015]

[0016] Such as figure 1 and figure 2 As shown, the upstream connection member 12 is made of hard plastic, has a cylindrical shape, and constitutes an inlet 16 of the intake pipe 10 . The upstream connection member 12 includes a cylindrical connection portion 12a, an annular pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com