Winter anti-freezing and wind energy recovery system for indirect air cooling power station

A recovery system and an indirect technology, applied to wind turbines, wind power generation, water shower coolers and other directions consistent with the wind direction, can solve the problems of unsatisfactory antifreeze effect and reduce the flow rate of cooling air, so as to reduce heat transfer, The effect of reducing wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

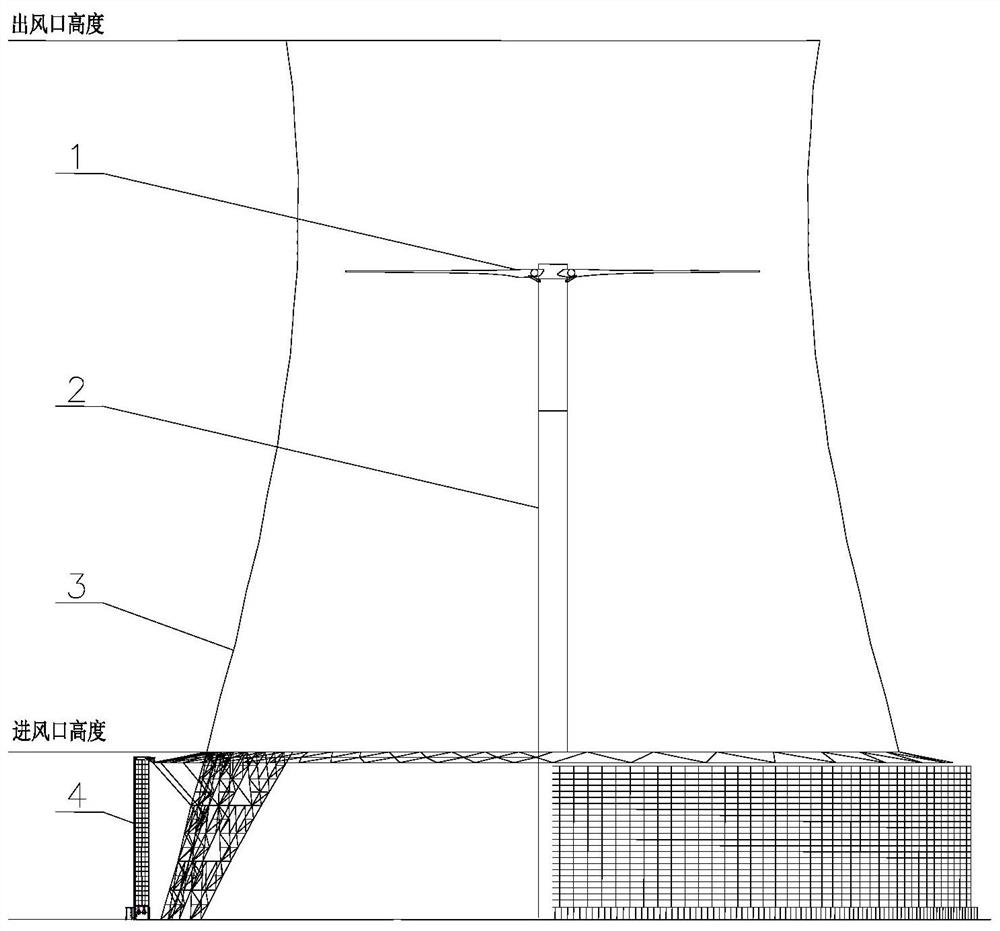

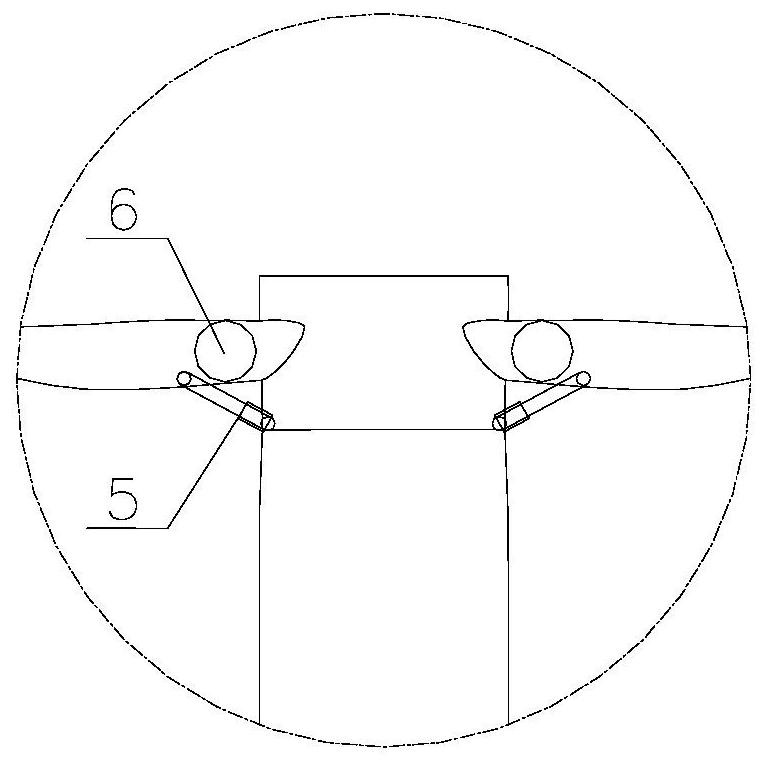

[0019] Embodiment 1 of the present invention: a winter antifreeze and wind energy recovery system for an indirect air-cooled power station, including a natural ventilation indirect air cooling tower 3 and an air cooling radiator 4, and the natural ventilation indirect air cooling tower 3 specifically adopts a hyperbolic cooling tower for air cooling and heat dissipation The device 4 is located at the bottom air inlet of the natural ventilation indirect air cooling tower 3. The system also includes a vertical axis wind power generator set 1 and a generator set pillar 2, the rotation axis of the vertical axis wind power generator set 1 is a vertical axis, and the generator set pillar 2 is located at the center of the natural ventilation indirect air cooling tower 3, The vertical axis wind power generator set 1 is installed on the upper part of the generator set pillar 2, the height of the vertical axis wind power generator set 1 is lower than the top height of the natural ventila...

Embodiment 2

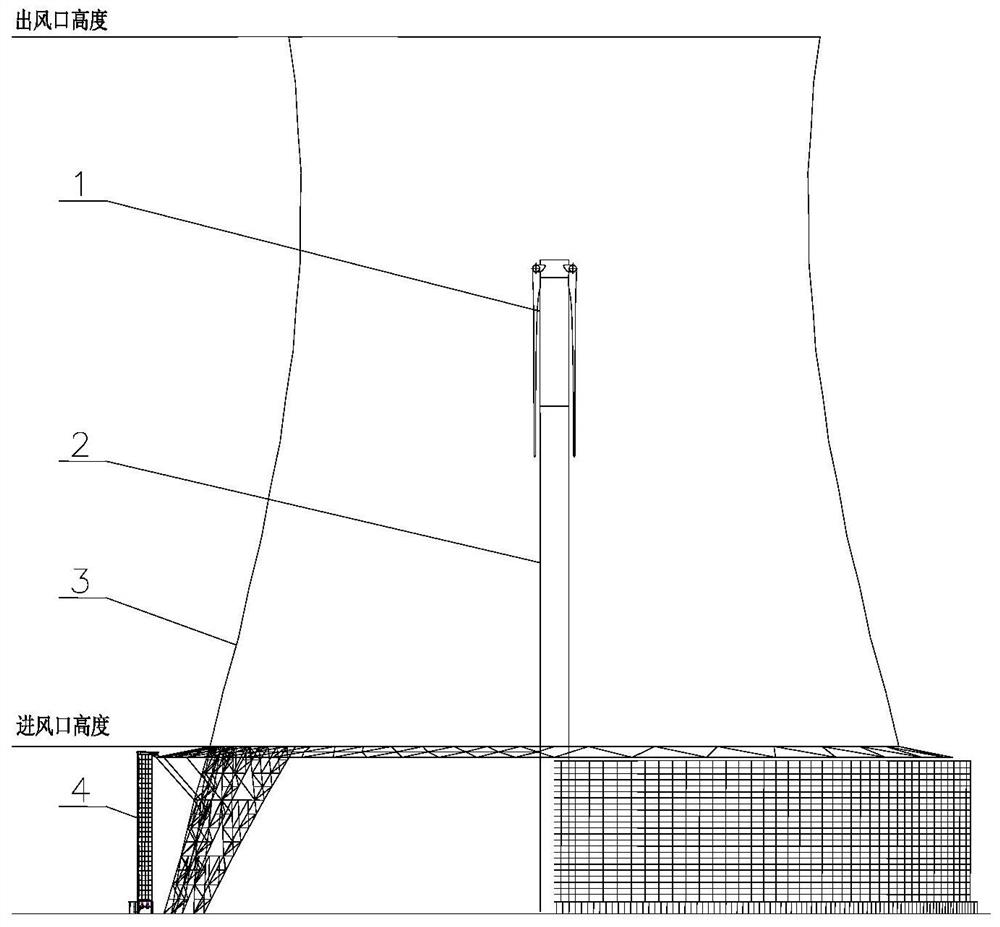

[0020] Embodiment 2: A winter antifreeze and wind energy recovery system for an indirect air-cooled power station, including a natural ventilation indirect air cooling tower 3 and an air cooling radiator 4, the natural ventilation indirect air cooling tower 3 specifically adopts a hyperbolic cooling tower, and the air cooling radiator 4 is located at At the bottom air inlet of natural ventilation indirect air cooling tower 3. The system also includes a vertical axis wind power generator set 1 and a generator set pillar 2, the rotation axis of the vertical axis wind power generator set 1 is a vertical axis, and the generator set pillar 2 is located at the center of the natural ventilation indirect air cooling tower 3, The vertical axis wind power generator set 1 is installed on the upper part of the generator set pillar 2, the height of the vertical axis wind power generator set 1 is lower than the top height of the natural ventilation indirect air cooling tower 3, specifically,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com