Observation method for foundation settlement of high-precision rolling mill

A basic settlement, high-precision technology, used in height/level measurement, measurement devices, surveying and navigation, etc., can solve problems such as unsatisfactory observation conditions, and achieve the effects of simple operation, high measurement accuracy, and accurate measurement values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

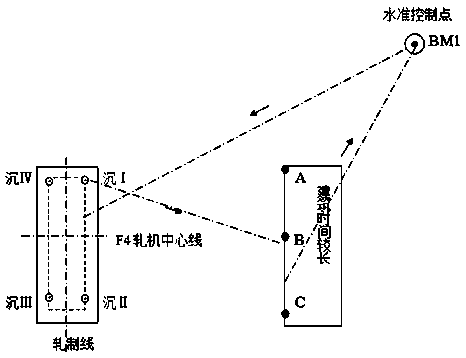

[0017] Such as figure 1 Shown: Observation method of high-precision rolling mill foundation settlement, which includes:

[0018] Choose a stable foundation in the side direction of the rolling line of the rolling mill, and set up 3 observation points at different positions, numbered as point A, point B, and point C, and the distance between the three points shall not exceed 50 meters;

[0019] In the first observation, the leveling control point BM was used to measure the four settlement points of the rolling mill, and the measured value was considered to be the correct value; then the first value of the sinking point I was used as the benchmark to measure the three points A, B, and C, and the obtained Output three values each, and finally close to the BMI standard point;

[0020] In the future, when observing the settlement point of the rolling mill, use point B as the benchmark for observation. For each observation, first check whether there is any change among the three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com