A method for measuring the percentage elongation after fracture and the percentage reduction of area after fracture of a tensile sample

A technique for area reduction and tensile specimens, applied to measuring devices, applying stable tension/pressure to test material strength, instruments, etc., can solve the problem of shape damage, harmfulness to human body, and microscopic analysis of tensile fractures, etc. problem, to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

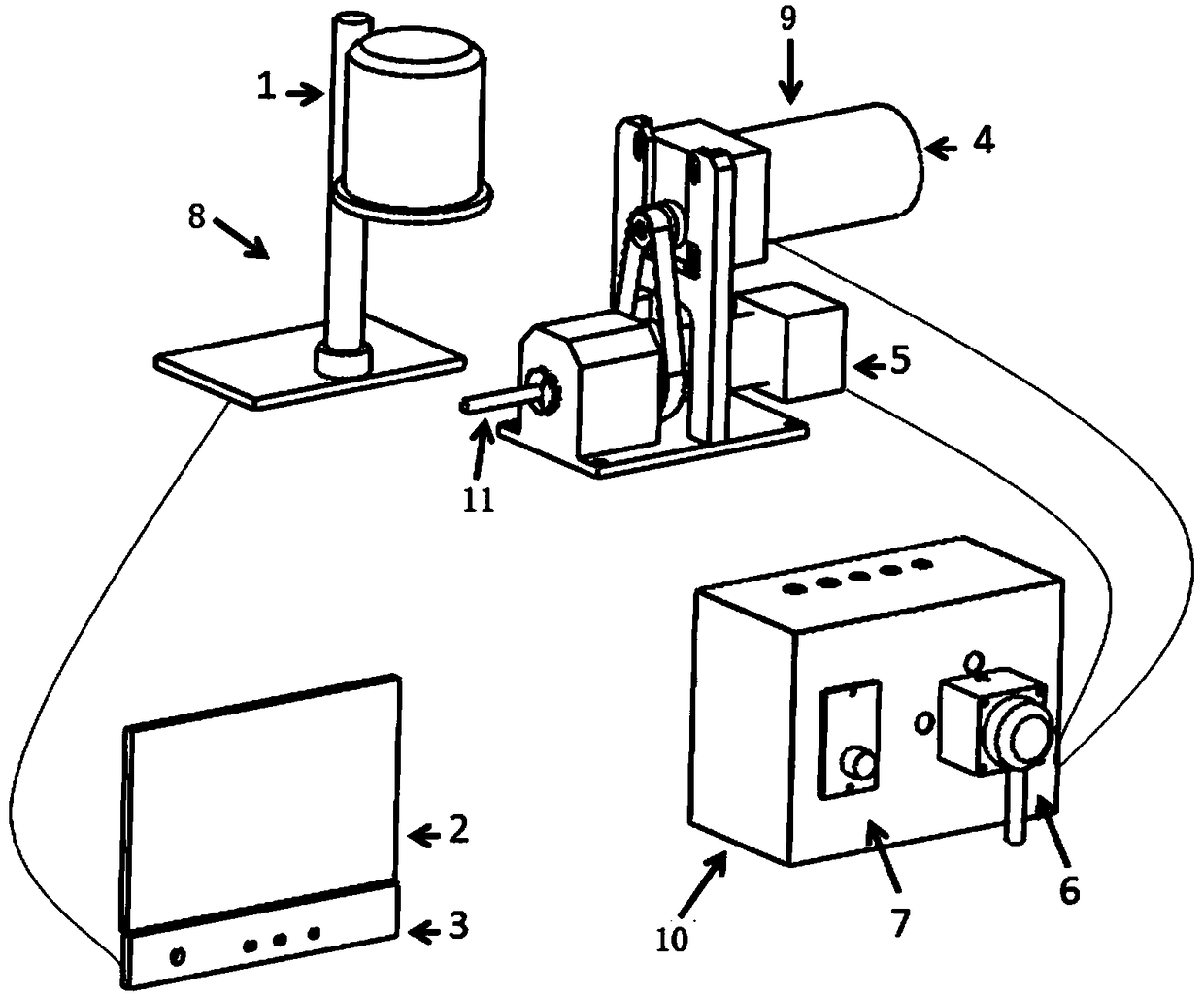

[0042] The composition structure of the exemplary device used in the method for measuring the elongation after fracture and the reduction of area of the tensile sample of the exemplary present invention is as follows: figure 2 As shown, it includes a photomicrograph system 8 , a rotating chuck 9 and a control box 10 .

[0043] The photomicrograph system 8 is used to take pictures of the tensile sample 11 at different positions. The photomicrograph system 8 includes a high-definition lens 1 , an image acquisition / control unit 3 and a display 2 . The image acquisition / control unit 3 is respectively connected with the high-definition lens 1 and the display 2, and is used to convert and transmit the image signal collected by the high-definition lens 1 to the display 2 for display, and control and save the high-definition pictures collected by the high-definition lens 1.

[0044] The rotary chuck 9 realizes the clamping and rotation of the tensile sample 11 under the remote con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com