Tea cake-pressing forming device for tea production

A forming device and tea technology, which is applied in the field of agricultural machinery, can solve the problems of incompleteness of tea cakes and easy adhesion of tea cakes, and achieve the effect of easy access and integrity assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

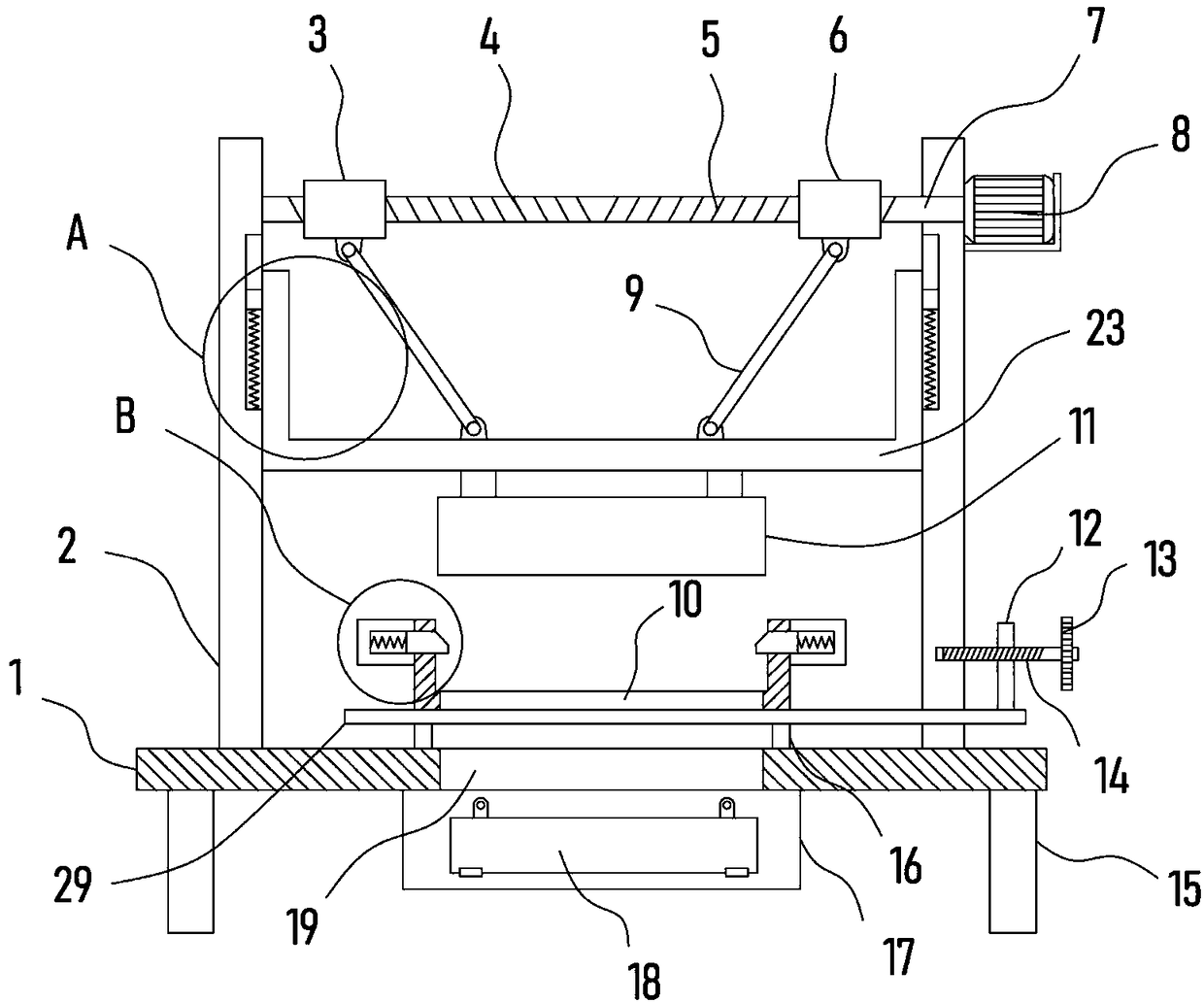

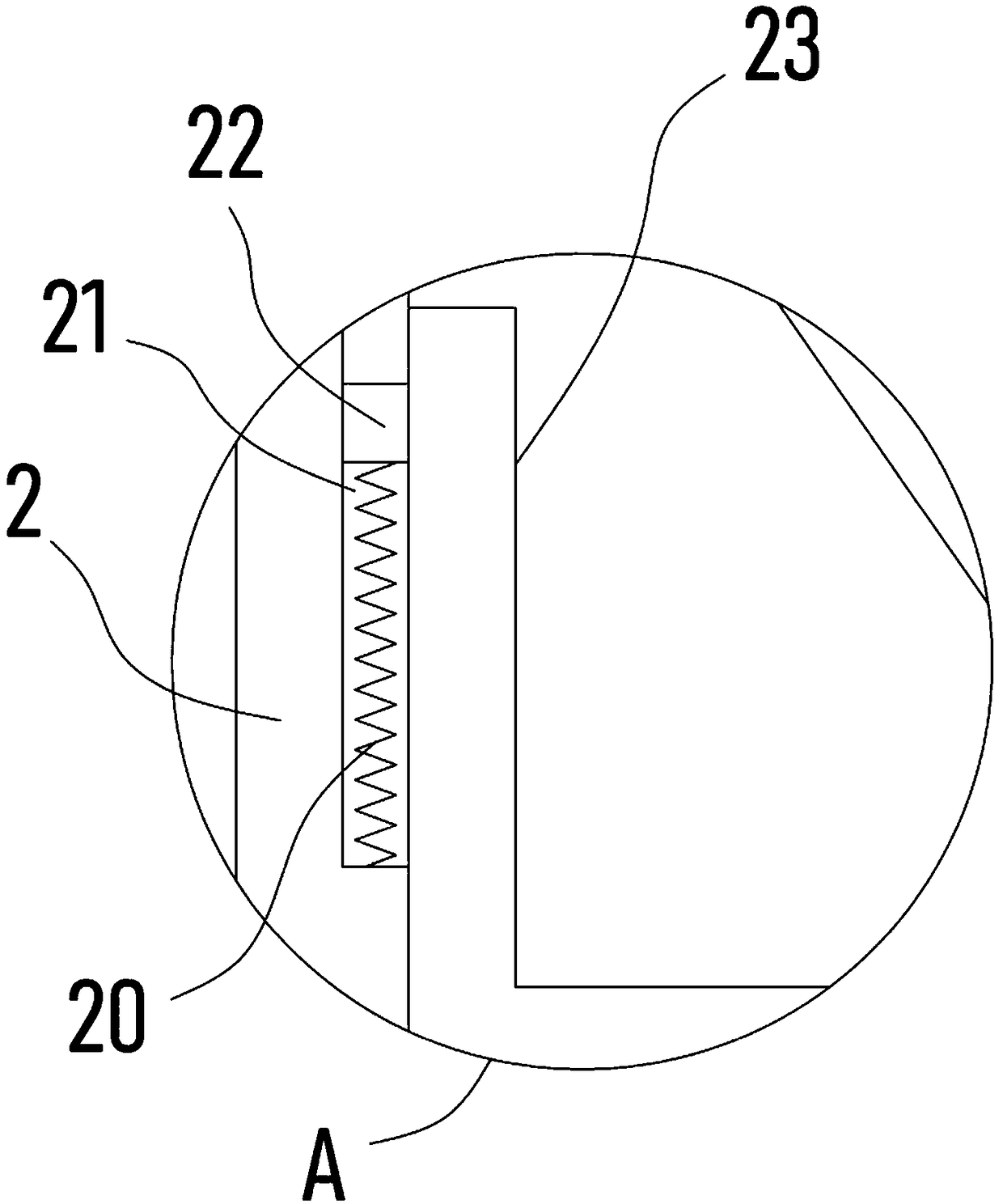

[0022] see Figure 1-4 , a tea cake press forming device for tea production, comprising a horizontal plate 1 and legs 15 fixed on the bottom of the horizontal plate 1, a support plate 2 is fixed vertically on the horizontal plate 1, and a support plate is fixed on the horizontal plate 1 Frame 16, and pressing groove 24 is fixed on the supporting frame 16, and pressing groove 24 is used for placing the tealeaves that will be pressed.

[0023] A pressing die 11 is arranged above the pressing tank 24, and the pressing die 11 is used to press the tealeaves in the pressing tank 24 into cakes. 2. The drive motor 8 is fixed on the side wall, and the output shaft of the drive motor 8 is coaxially fixed with the drive shaft 7. The surface of the drive shaft 7 is tapped with external threads I4 and II5 in opposite directions. The threaded connection sleeve is fixed with a threaded block I3 and a threaded block II6, and a support rod 9 is hinged between the threaded block I3, the thread...

Embodiment 2

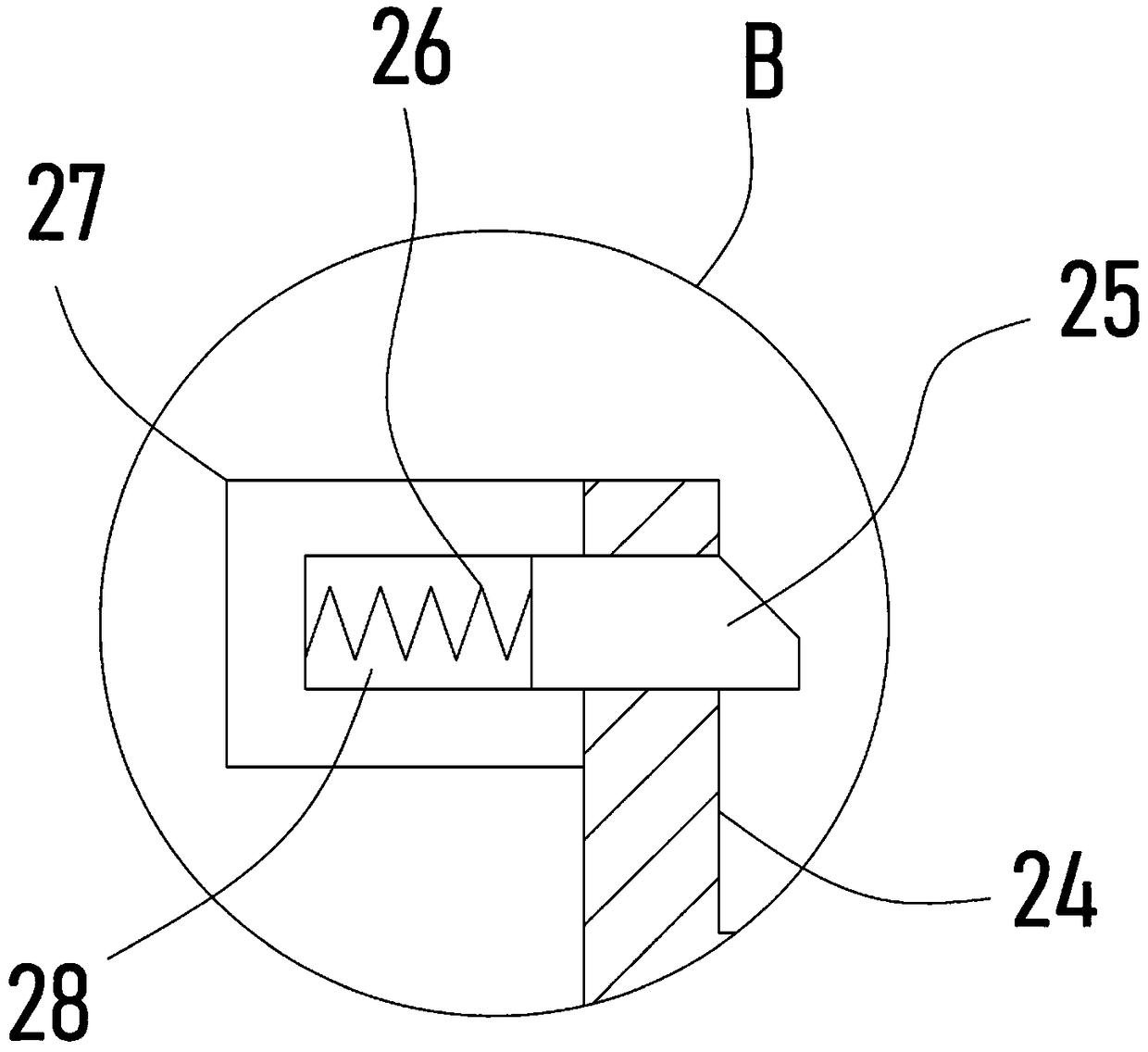

[0028] On the basis of Embodiment 1, in addition, a pressing hole 10 is provided at the bottom of the pressing groove 24, and a movable baffle 29 is horizontally slidable below the pressing hole 10, and a blanking vertically corresponding to the pressing hole 10 is provided on the horizontal plate 1. Passage 19, the bottom of horizontal plate 1 is fixedly installed with the accommodation box 17 that communicates with blanking passage 19, and the side wall hinge of accommodation box 17 is connected with dodge door 18.

[0029] Further, the limit plate 12 is vertically fixed on the movable baffle plate 29, the threaded connection on the limit plate 12 is provided with a threaded rod 14, the threaded rod 14 is threaded with the support plate 2 threaded rod 14, and the end of the threaded rod 14 is fixed There are runners 13.

[0030] After the tea cake is pressed, the rotation drives the threaded rod 14 to rotate and separate from the support plate 2. At this time, the limit plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com