Nail hole machine for enabling whole pickled vegetables to be tasty

A flavoring machine and kimchi technology, which is applied in food science and other directions, can solve the problems of affecting the taste, the kimchi is not tasted well, and the seasoning is lost, and achieves the effect of improving punching efficiency and improving food hygiene and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail by specific embodiment now in conjunction with accompanying drawing:

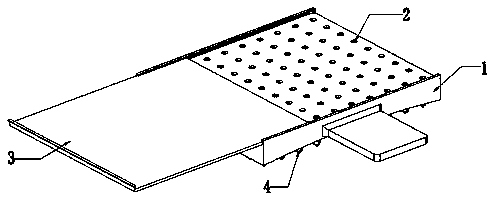

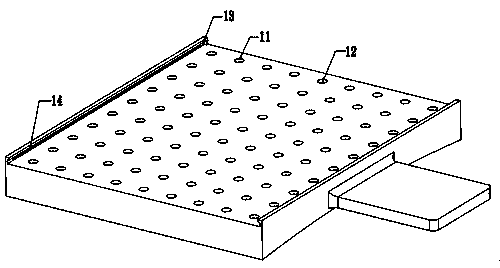

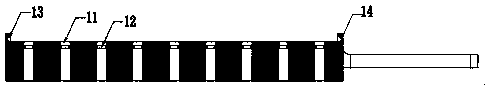

[0023] like Figure 1 to Figure 8 As shown, a nail hole flavoring machine for whole pickles, said nail hole flavoring machine for whole pickles includes a clapper (1), a spring (2), a baffle (3), a punching piece ( 4); the clapper (1) is rectangular, with a handle at the center of the tail end; the spring (2) is installed inside the clapper (1) to connect and fix the spring (2); the baffle (3) Installed in the top of the clapper (1); the punching part (4) is installed in the clapper (1).

[0024] like Figure 1 to Figure 8 Shown is the example of the present invention, when needing to use the nail-hole flavoring machine that is used for whole kimchi, first open baffle plate 3 by handle 31, now the guide slider 32 on the baffle plate 3 will be on the baffle plate on the clapper plate 1 top Slide in the guide chute 14 in the plate groove 13, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com