Integrated die with trimming, punching and correction functions

A cutting edge punching, die technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of increased deformation resistance of forgings, difficulty in correcting and leveling, and increased difficulty in correction, so as to reduce the deformation of forgings, The effect of reducing operators and equipment and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

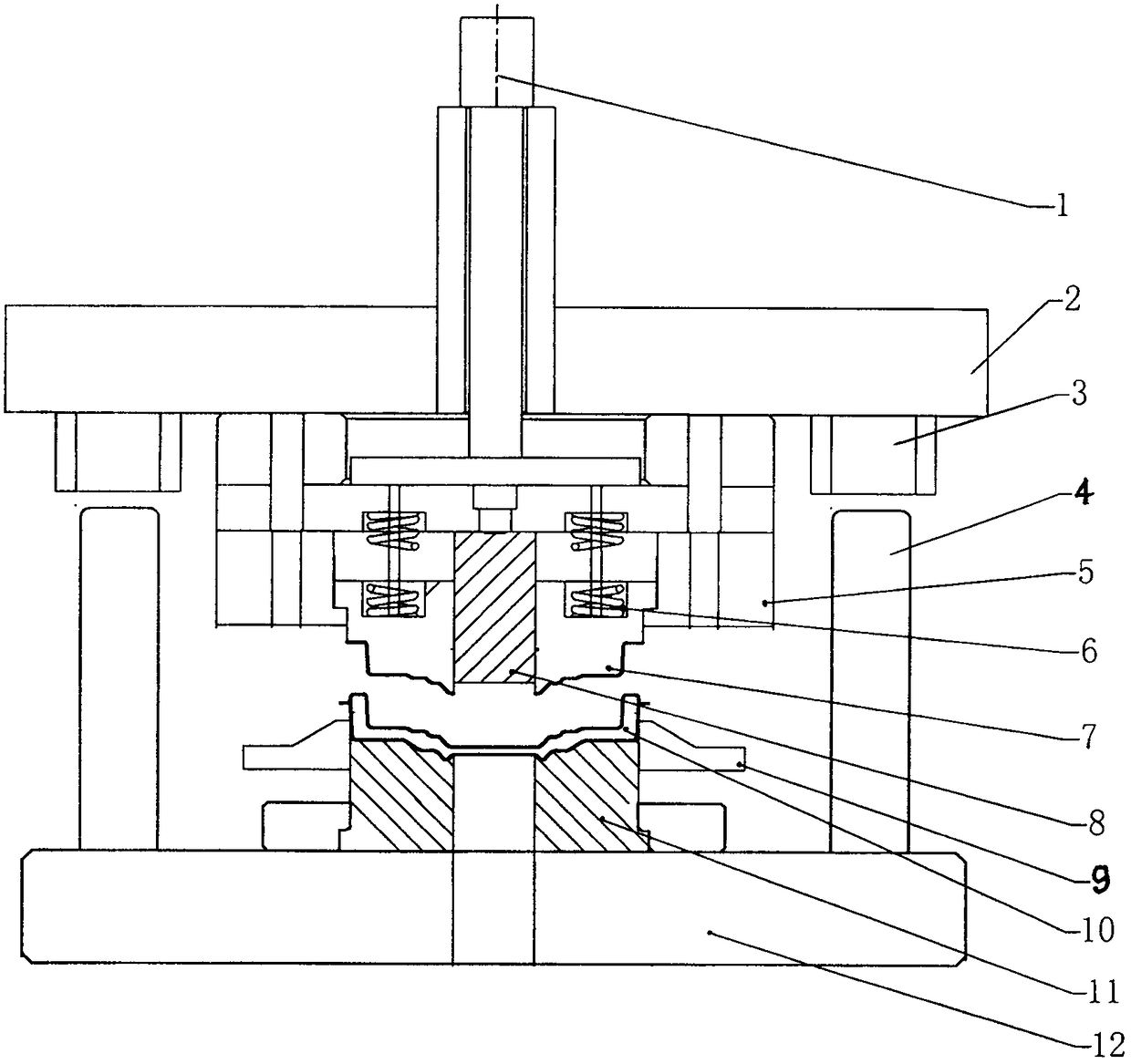

[0009] refer to figure 1 It can be seen that the trimming, punching and correction integrated mold of the present invention includes an upper base plate 2 and a lower template 12, a trimming upper die 5 is installed under the upper base plate 2, and a trimming upper die 5 is installed under the upper base plate 2 and on the trimming upper die. 5 is equipped with a thermal correction upper mold 7, under the upper base plate 2, and in the thermal calibration upper mold 7, a punching punch 8 is housed, and on the lower template 12, a trimming upper mold (and a punching punch) is installed. head) position corresponding trimming correction lower mold 11. A stripping plate 9 is installed on the side of the mold 11 under the trimming correction. On the upper bottom plate 2, the upper ejector rod 1 connected with the punching head is installed. A guide sleeve 3 is installed under the side of the upper bottom plate 2 , and a guide post 4 corresponding to the position of the guide sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com