Welding device for welding steel trusses

A technology of welding device and steel truss, which is applied in the direction of welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of poor welding angle, low efficiency, and affecting the quality of use, so as to facilitate operation, improve quality, and improve welding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

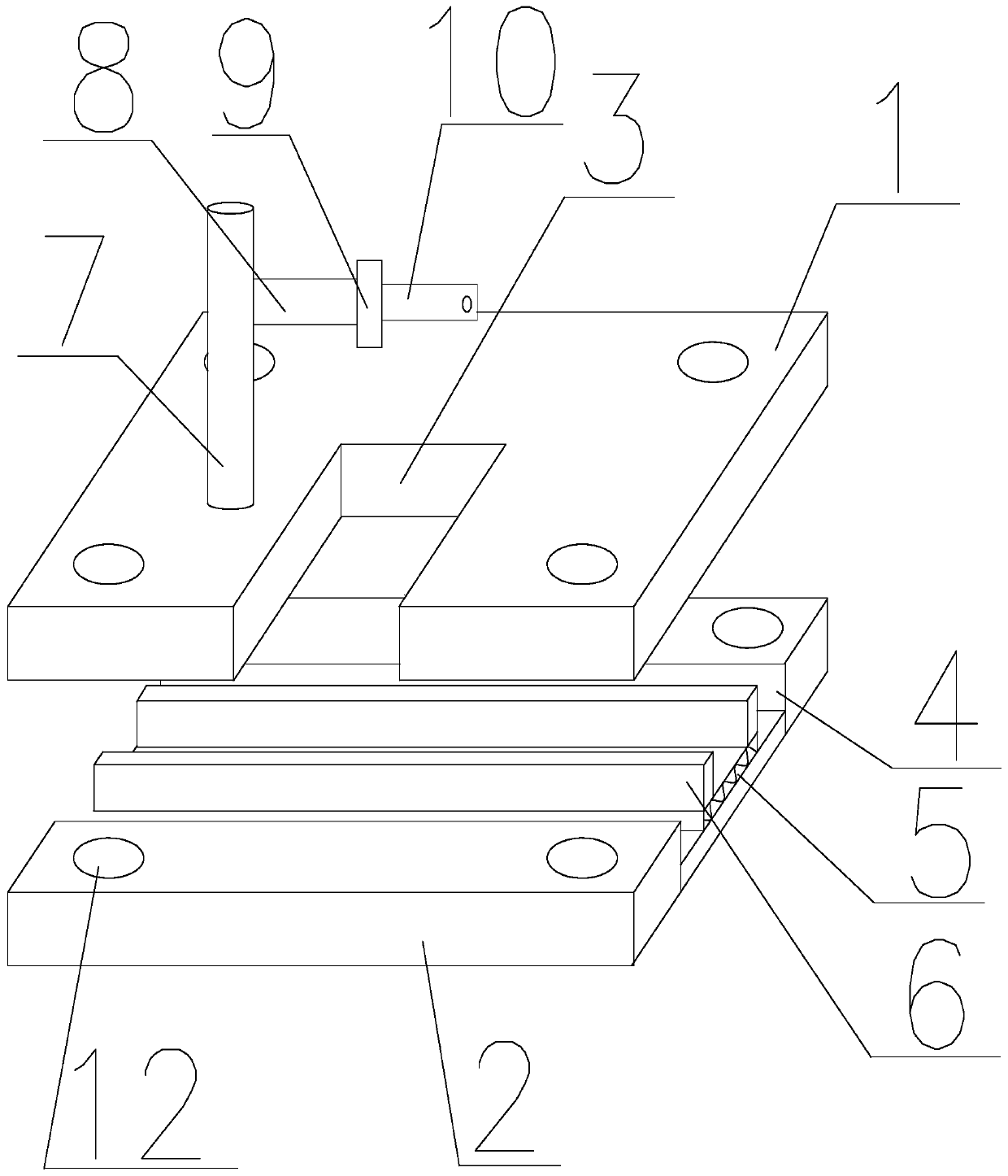

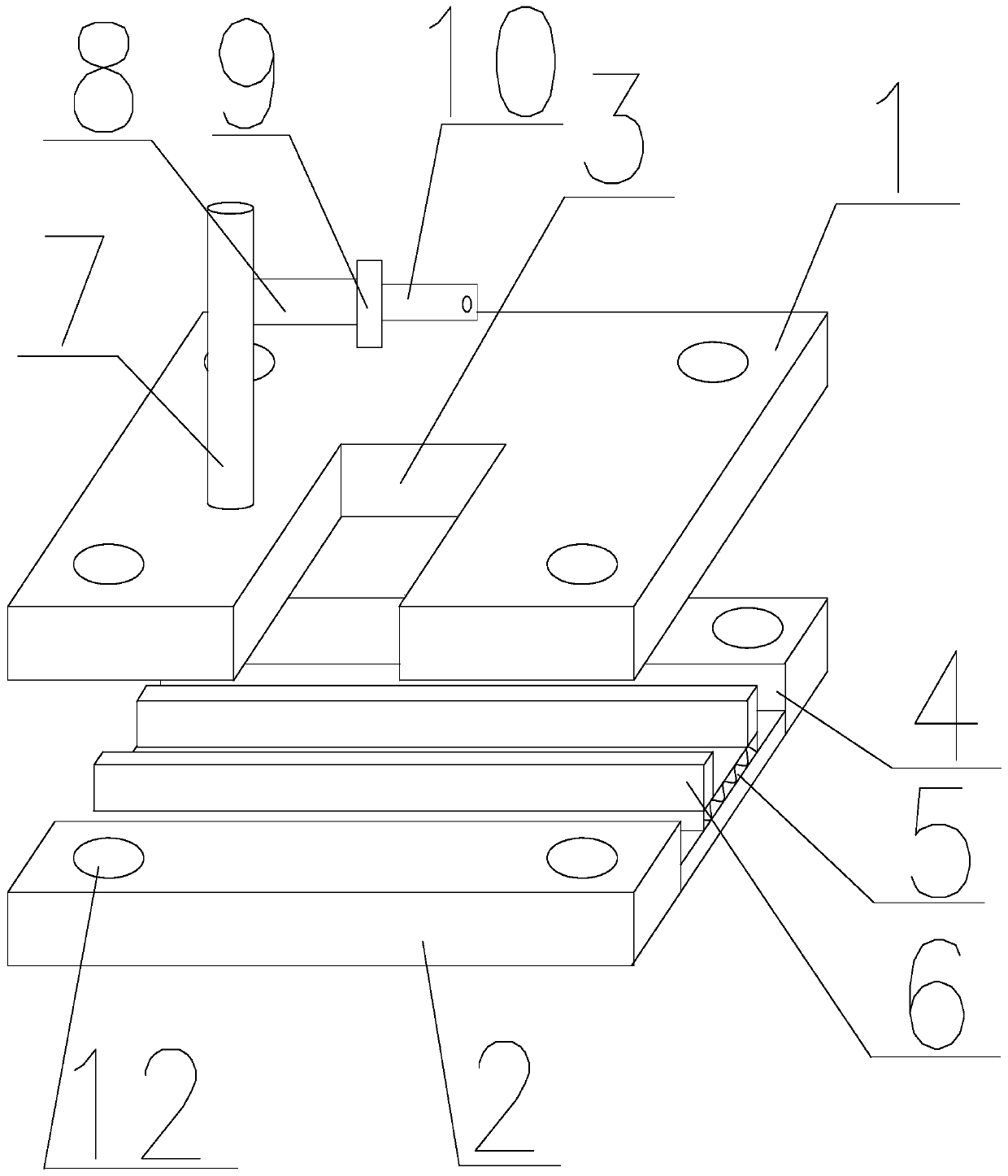

[0030] Such as figure 1 and figure 2As shown, the welding device for welding steel trusses of the present invention includes steel pipes for welding trusses and fixing devices for fixing steel pipes. The fixing devices include a first fixing plate 1 and a second fixing plate 2, and the first fixing plate 1 is located directly above the second fixed plate 2, and the first fixed plate 1 is provided with a first groove 3 on a horizontal plane with one end penetrating through the side of the first fixed plate 1 and the other end inside the first fixed plate 1. The two fixed plates 2 are provided with second grooves 4 on the horizontal plane with two ends penetrating through the opposite two sides of the second fixed plate 2, and the inner bottom surface of the second grooves 4 can be arranged along the width of the second grooves 4. direction telescopic spring plate 5, the two ends of spring plate 5 telescopic ends are all vertically connected with fixed plate 6, the distance be...

Embodiment 2

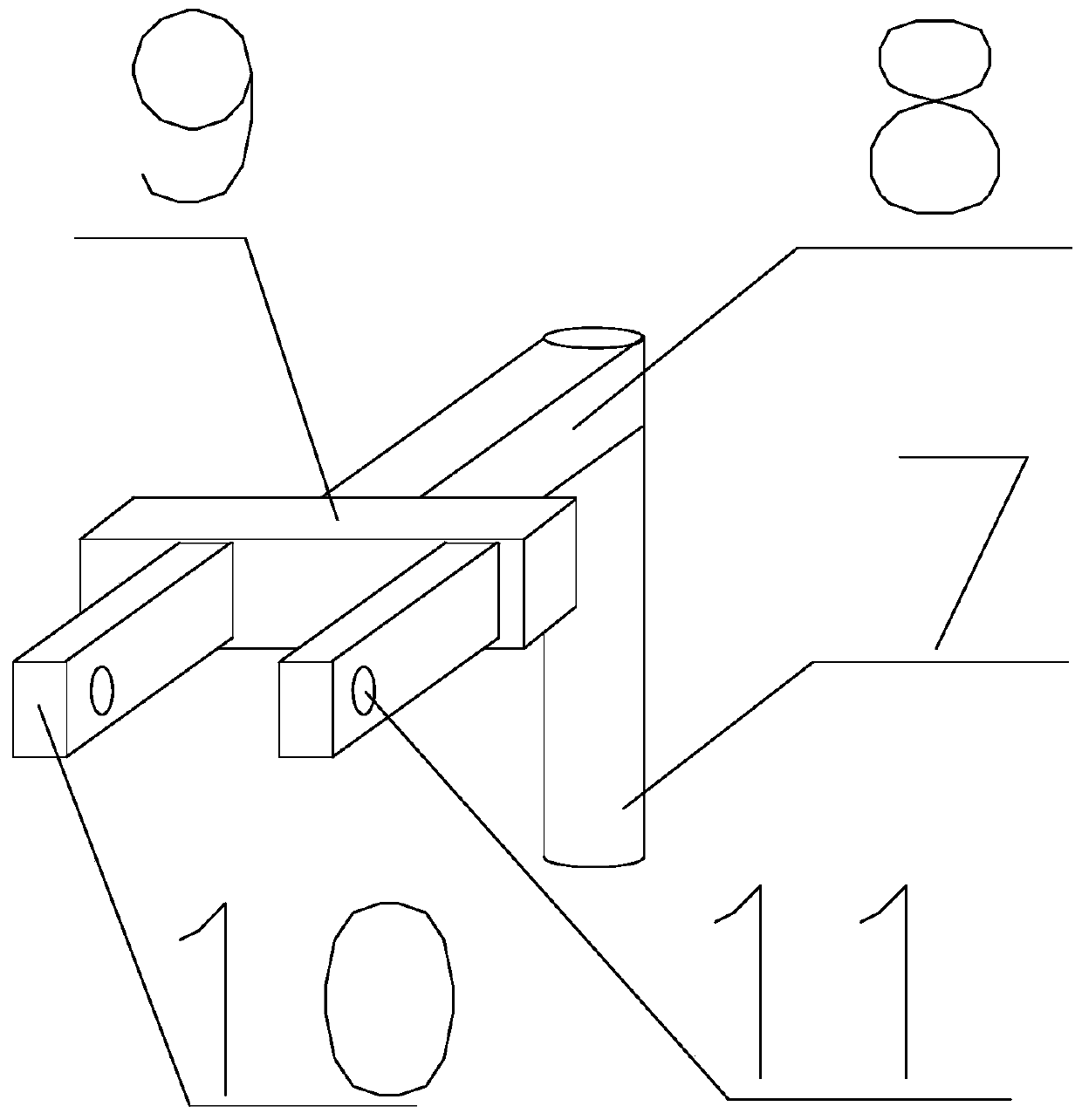

[0032] The welding device for welding steel trusses, on the basis of Embodiment 1, the clamping device includes two connecting plates 10 vertically arranged on the first support rod 9 at one end, the connecting plates 10 are located on the horizontal plane, and are located in the first concave Above the groove 3, a chute on the horizontal plane is provided on the surface connecting the first support rod 9 and the connecting plate 10, one end of the connecting plate 10 slides along the direction of the chute, and the other end of the connecting plate 10 is provided with a fixed Groove 11, fixing groove 11 is fixedly connected through bolt penetration, steel pipe is fixed between two connecting plates 10, connecting plate 10 slides along the chute, and is fixedly connected to the steel pipe that is located in between through fixing groove 11 by bolt. Several convex lines are arranged on two opposite surfaces of the connecting plate 10, and the convex lines are made of rubber mate...

Embodiment 3

[0034] A welding device for welding steel trusses, the horizontal sections of the first fixed plate 1 and the second fixed plate 2 are squares of the same size, and the four through grooves 12 on the first fixed plate 1 and the second fixed plate 2 are surrounded by into squares of equal size. When welding three steel pipes on the same plane, one end of steel pipe A and steel pipe B are in contact with each other and connected with the side of steel pipe C, and the angles between steel pipe A, steel pipe B and steel pipe C are all 45 degrees. The steel pipe C is placed between two fixed plates 6, fixedly connected by the spring plate 5, then the steel pipe A is clamped on the clamping device, and the lengths of the first telescopic rod 7 and the second telescopic rod 8 are adjusted to make the steel pipe The lower end of A is in contact with the side of steel pipe C, and the angle between steel pipe A and steel pipe C is 45 degrees. Rotate the connecting rod as needed so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com