Grinding wheel improving grinding cooling and grinding quality

A grinding wheel and grinding technology, applied in the direction of bonded grinding wheels, abrasives, metal processing equipment, etc., can solve the problems such as the inability to dissipate the grinding heat in time, the short dressing interval of the grinding wheel, and the reduction of grinding efficiency, and achieve good centrifugal throwing effect. , Reduce grinding scratches and improve the effect of grinding surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

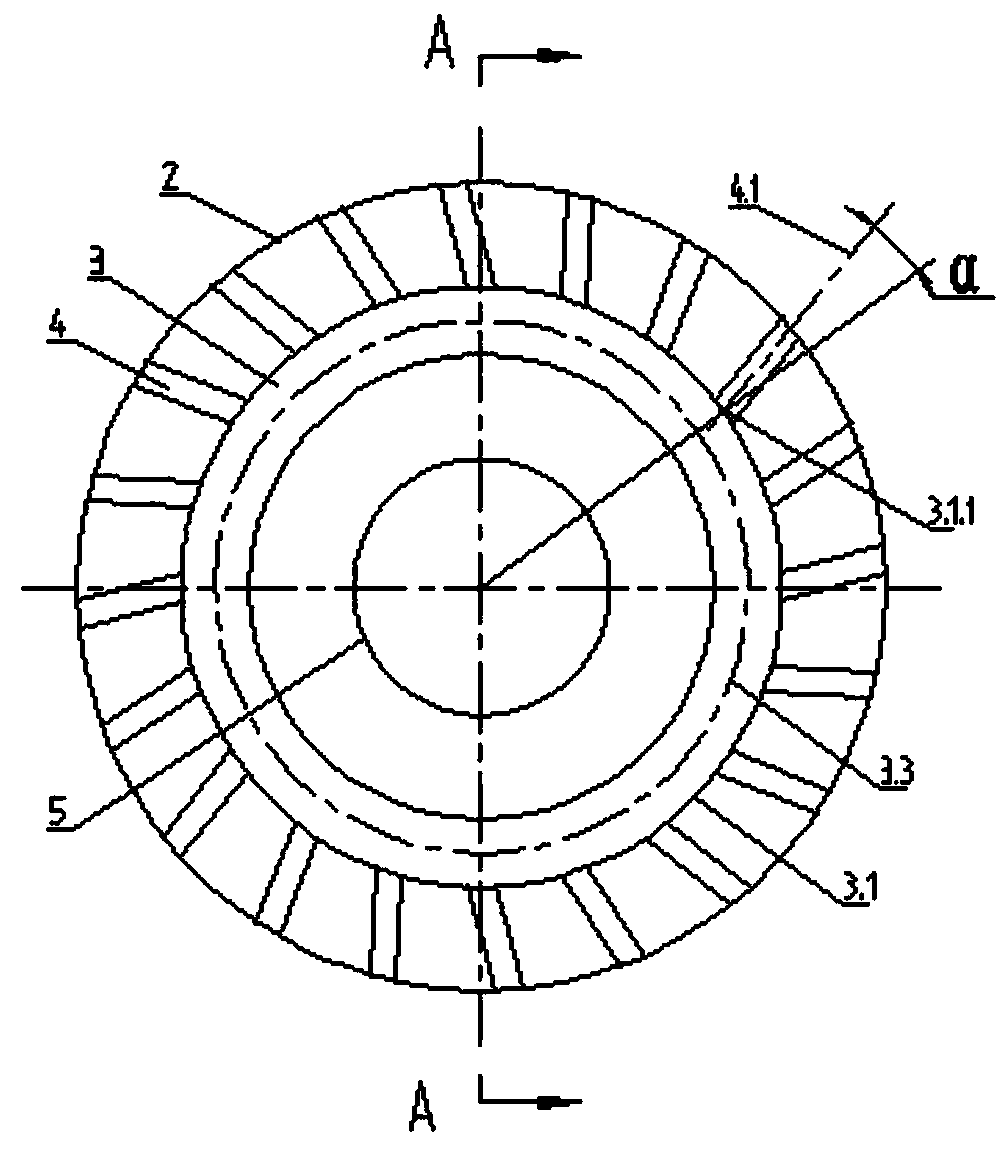

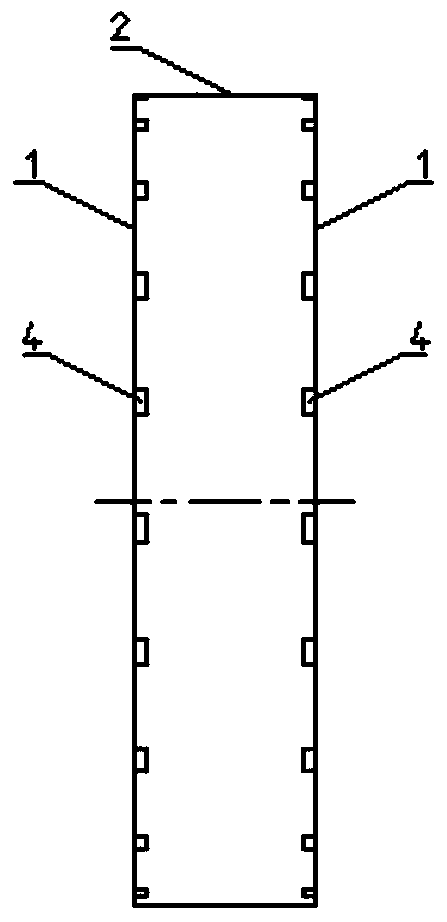

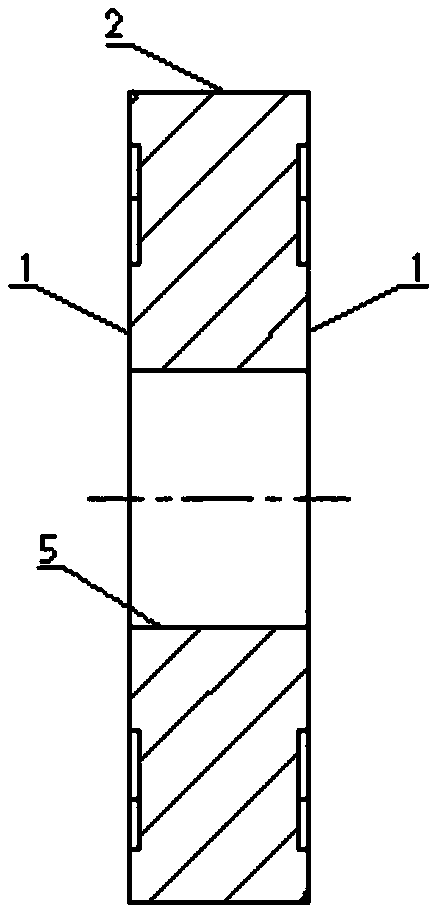

[0018] The grinding wheel shown in the accompanying drawings to improve the heat dissipation of grinding and improve the grinding quality is a grinding wheel with a thickness ≥ 20 mm and a grinding wheel diameter greater than 200 mm but not greater than 500 mm. The two ends 1 of the grinding wheel are respectively provided with a center of the outer circular surface 2 of the grinding wheel. An annular groove 3 with coaxial axes, the diameter of the central axis 3.3 of the annular groove 3 is half of the sum of the diameter of the outer circular surface 2 and the inner hole 5 of the grinding wheel, the width of the annular groove 3 is 5mm, and the depth is 1mm .

[0019] On the circumference between the annular groove 3 of each end face 1 of the described grinding wheel and the outer circular surface 2, there are 20 straight grooves 4 that are evenly distributed, eccentric, and communicate with the annular groove 3 and the outer circular surface 2 (in other embodiments , can be...

Embodiment 2

[0021] The grinding wheel shown in the accompanying drawings to improve the heat dissipation of grinding and improve the grinding quality is a grinding wheel with a thickness ≥ 20 mm and a grinding wheel diameter greater than 200 mm but not greater than 500 mm. The two ends 1 of the grinding wheel are respectively provided with a center of the outer circular surface 2 of the grinding wheel. An annular groove 3 with coaxial axes, the diameter of the central axis 3.3 of the annular groove 3 is 1 / 3 of the sum of the diameter of the outer circular surface 2 of the grinding wheel and the diameter of the inner hole 5, the width of the annular groove 3 is 10 mm, and the depth is 2mm.

[0022] On the circumference between the annular groove 3 of each end face 1 of the described grinding wheel and the outer circular surface 2, there are 20 straight grooves 4 that are evenly distributed, eccentric, and communicate with the annular groove 3 and the outer circular surface 2 (in other embod...

Embodiment 3

[0024] The grinding wheel shown in the accompanying drawings to improve the heat dissipation of grinding and improve the grinding quality is a grinding wheel with a thickness ≥ 20 mm and a grinding wheel diameter greater than 500 mm but not greater than 600 mm. The two ends 1 of the grinding wheel are respectively provided with a center of the outer circular surface 2 of the grinding wheel. An annular groove 3 with coaxial axes, the diameter of the central axis 3.3 of the annular groove 3 is 2 / 3 of the sum of the diameter of the outer circular surface 2 of the grinding wheel and the diameter of the inner hole 5, the width of the annular groove 3 is 15mm, and the depth is 2mm.

[0025] On the circumference between the annular groove 3 of each end face 1 of the described grinding wheel and the outer circular surface 2, there are 20 straight grooves 4 that are evenly distributed, eccentric, and communicate with the annular groove 3 and the outer circular surface 2 (in other embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com