Passive decoupling mechanism for joint movement of tandem rope-driven manipulator

A joint motion and manipulator technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of joint motion coupling of serial rope-driven manipulators, and achieve the effects of less wear, less breakage, and simplified design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

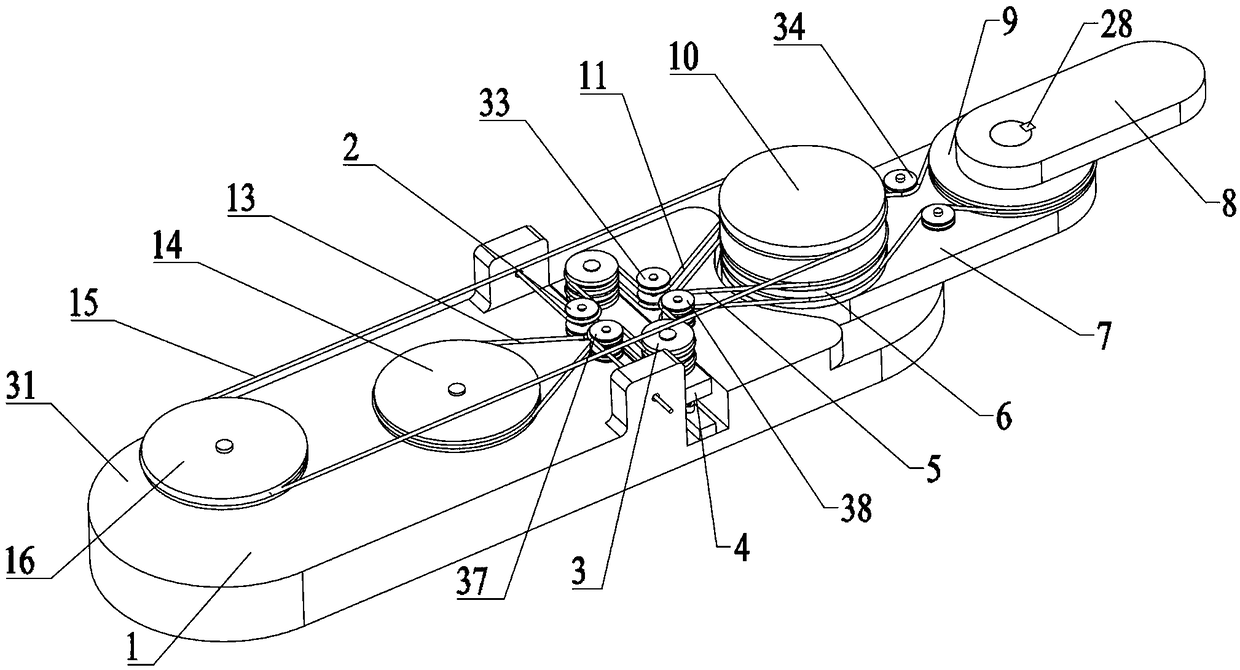

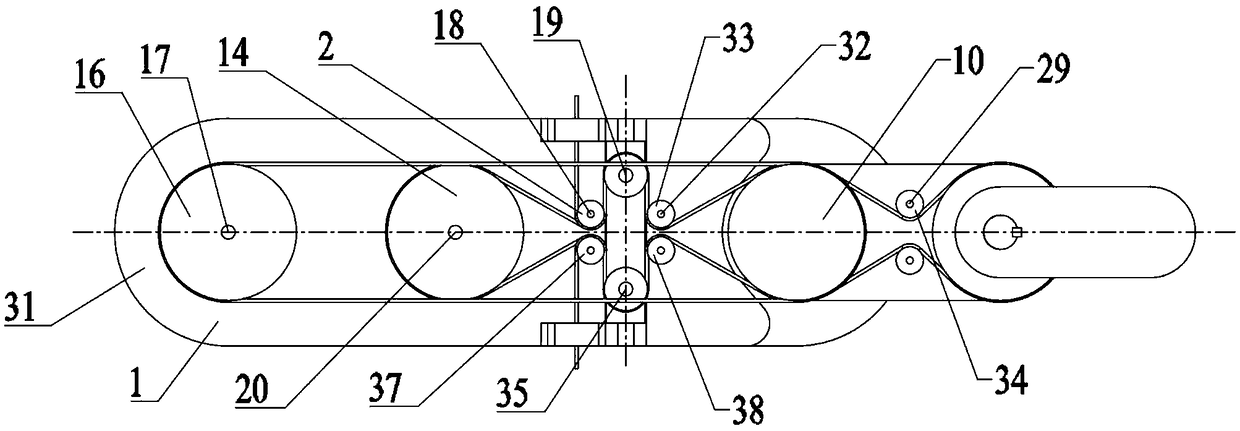

[0037] refer to figure 1 , the passive decoupling mechanism for the joint motion of the serial rope-driven manipulator according to the present invention includes a base system 1, a decoupling module 4, a No. 1 decoupling rope 5, a No. 1 arm system 7, a No. 2 arm 8, and a No. 2 solution Coupling rope 11, No. 2 driving rope 13 and No. 1 driving rope 15;

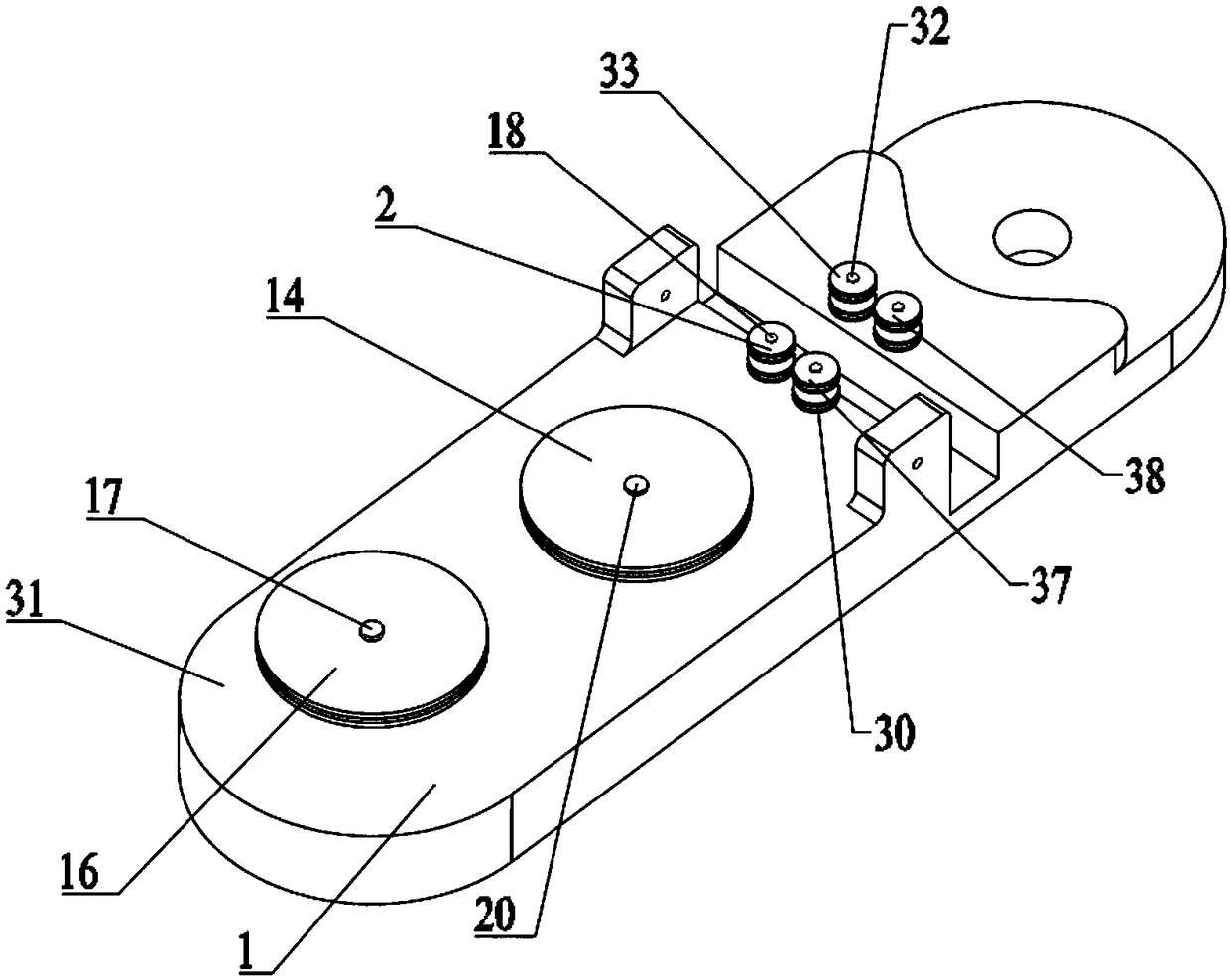

[0038] refer to figure 2 and image 3 , the base system 1 includes No. 1 guide wheel set 2, No. 2 driving wheel 14, No. 1 driving wheel 16, No. 1 pin 17, 2 No. 3 pins 18, No. 2 pin 20, base Plate 31, 2 No. 6 pins 32 with the same structure, No. 2 guide wheel group 33, No. 3 guide wheel group 37 and No. 4 guide wheel group 38.

[0039] Described No. 1 guide wheel set 2 is made up of two small pulleys 30, and two small pulleys 30 are vertically stacked and installed, and their centerlines coincide. The small pulley 30 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com