Non-contact power transmission structure for sliding door

A non-contact, sliding door technology, used in power control mechanisms, wing control mechanisms, doors, etc., can solve problems such as power cable exposure, passenger injury, power cable damage, etc., to improve aesthetic appearance and reduce injuries. Possibility, effect of preventing abnormal action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, exemplary embodiments will be described in more detail with reference to the accompanying drawings. It should be understood that these embodiments can be modified in various ways, and the scope of the present disclosure should not be construed as being limited to the following embodiments. These examples are provided in order to more fully explain the present invention to those skilled in the art.

[0041] Also, in the specification, the terms "˜unit' and '˜module' refer to a unit for processing at least one function or operation, and may be realized by hardware, software, or a combination of hardware and software.

[0042] The terms "electrical energy" and "power" described herein are used in a sense that includes all energy generated by current and voltage applied to operate the load 140 .

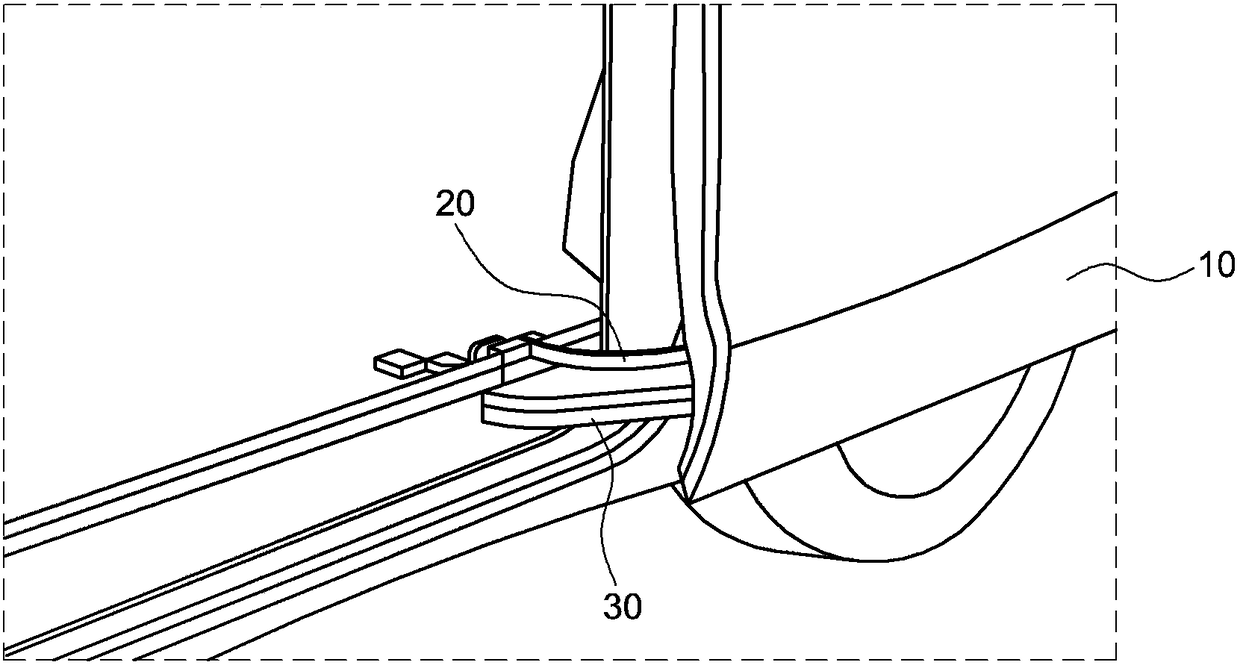

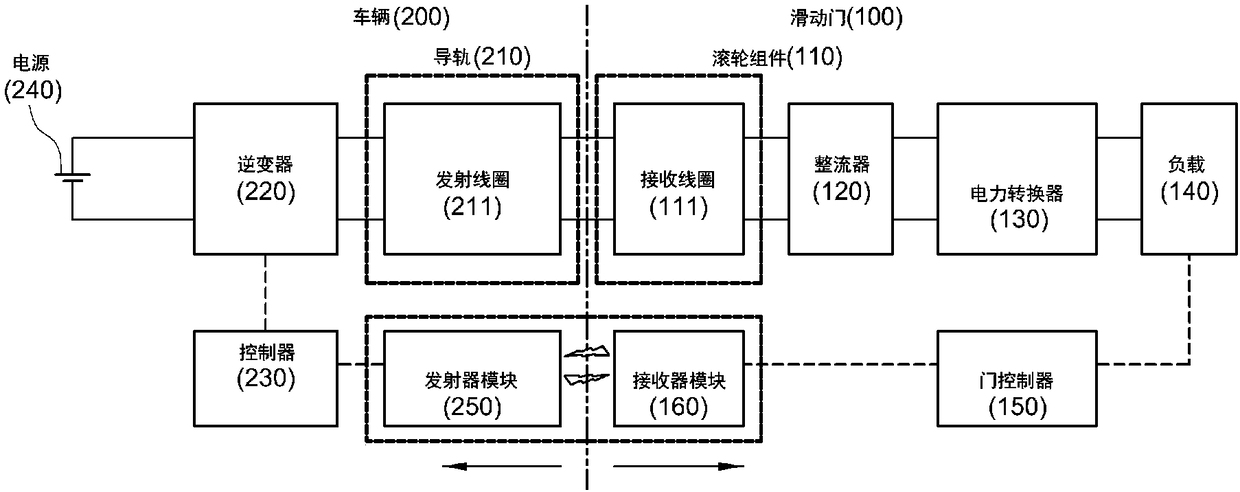

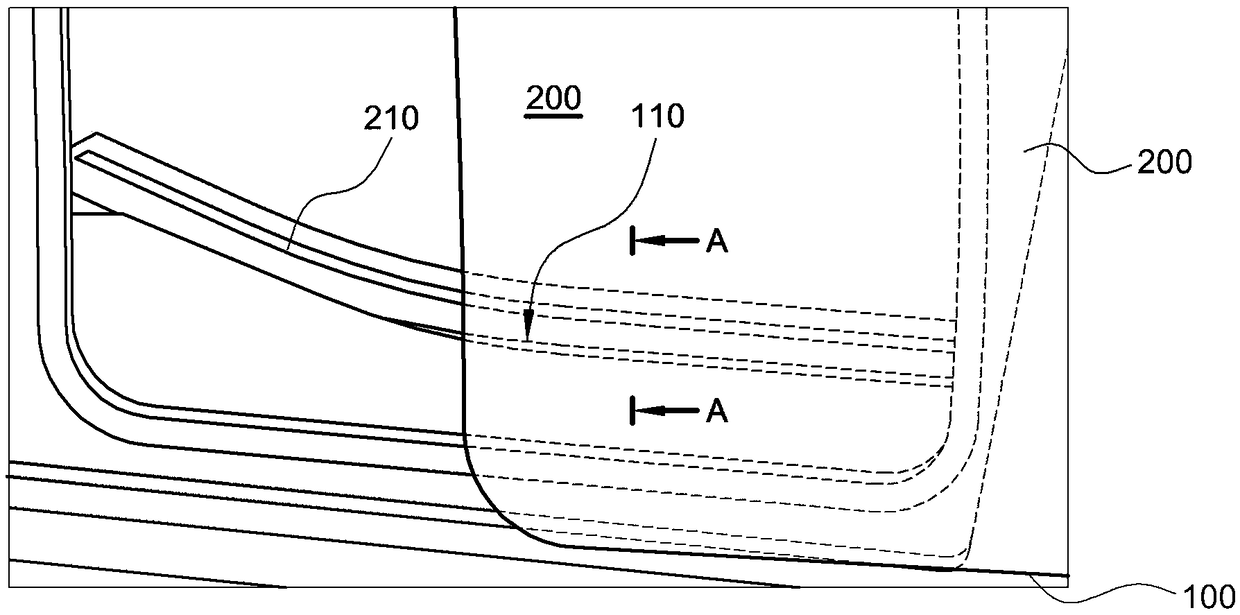

[0043] The present disclosure relates to a non-contact power transfer structure for a sliding door 100, that is, to a structure including at least one or more guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com