Bag propping-up machine and bag propping-up method

A technology of bag support and bag support claws, which is applied in the field of packaging equipment, can solve the problems of reduced production efficiency, broken bags, low loading efficiency, etc., and achieve the effects of high production efficiency, stable opening and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

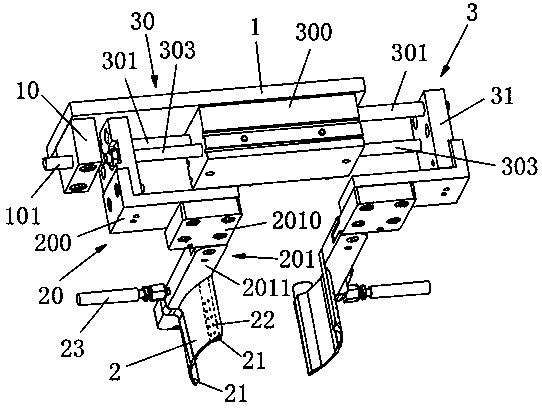

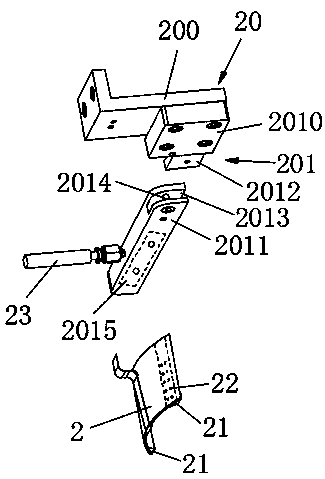

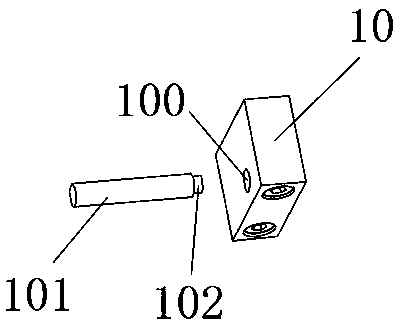

[0034] see Figure 1 to Figure 6 , a bag-holding mechanism, comprising a mounting plate 1, two oppositely disposed bag-holding claws 2, and a driving device 3 fixed on the mounting plate 1; the two bag-holding claws 2 are respectively fixed to the driving device 3 through connectors 20 On both sides, the distance between the two bag-holding claws 2 is changed through the expansion and contraction of the driving device 3; the inside of the bag-holding claw 2 is provided with a vacuum chamber 21, and the outer wall of the bag-holding claw 2 is provided with a plurality of suction holes 22, and the vacuum chamber 21 is connected with the suction chamber. The hole 22 communicates; the vacuum chamber 21 communicates with the suction port of the vacuum generator 23; the two bag-holding claws 2 are located in the bag, and the bag is adsorbed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com