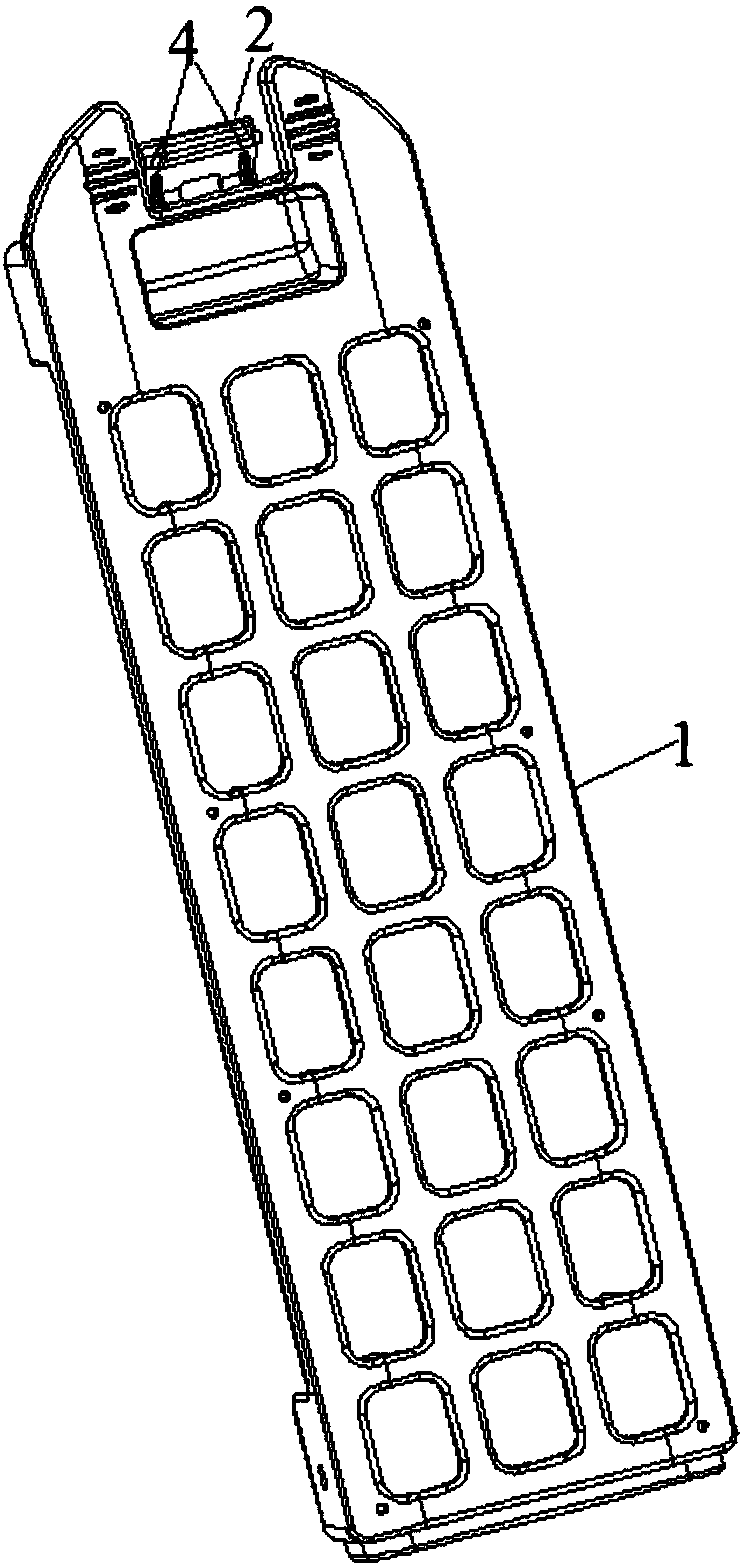

Filter device for thread scraps and washing machine provided therewith

A lint filter and filter technology, applied in the field of washing machines, can solve the problems of falling off, plastic deformation, unusability, etc., and achieve the effect of increasing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

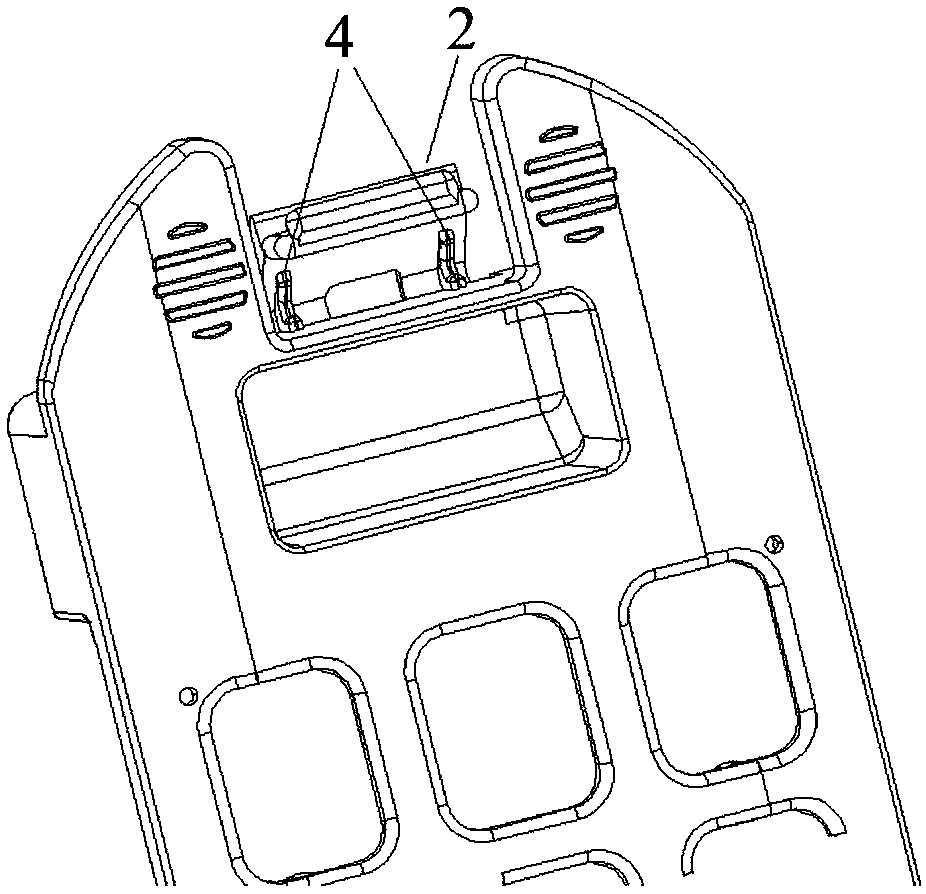

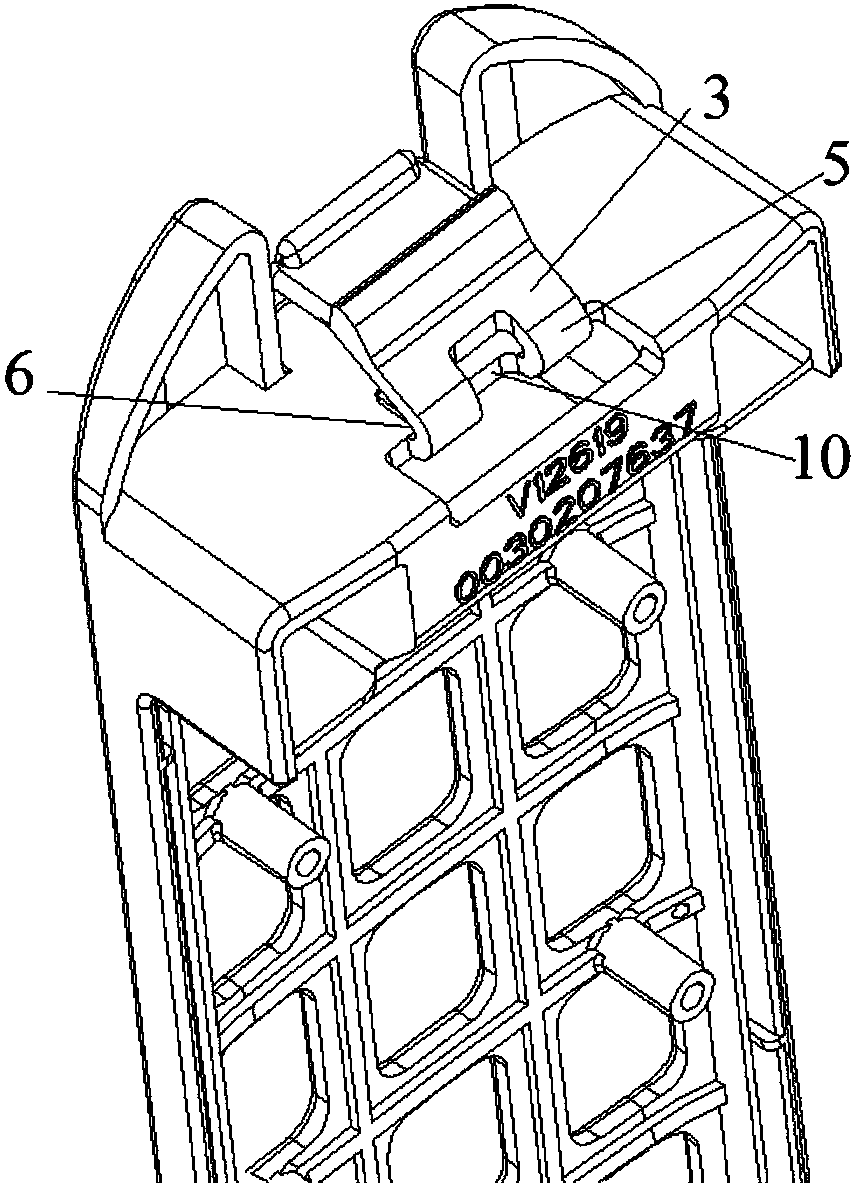

[0042] Such as figure 2 , Figure 4As shown, the reinforcement structure 4 in this embodiment is a support rib, which protrudes from the concave surface 6 and extends from the first extension surface 7 to the third extension surface 9, and is symmetrically distributed in the vertical direction of the force direction when the claw is pressed, preferably Yes, the support rib and the claw 2 are integrally designed.

Embodiment 2

[0044] Such as figure 2 As shown, this embodiment is further improved on the basis of Embodiment 1. A notch 10 is provided on the elastic support part 3. In the vertical direction of the force direction when the claw is pressed, the notch 10 is located at the center, and the reinforcement structure 4 It is two supporting ribs, and the two supporting ribs are symmetrically distributed on both sides of the gap 10 .

Embodiment 3

[0046] In this embodiment, at least two notches 10 are also provided on the elastic support part 3, and the notches 10 are symmetrically distributed in the vertical direction of the force direction when the claw is pressed, and the reinforcing structure 4 includes at least two supporting ribs, which are symmetrically distributed in the notches 10 sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com