Underwear mold cup and inner-layer three-dimensional printing point embossing pattern non-deformation mold pressing process thereof

An inner layer and underwear technology, applied in underwear, baby underwear, bras, etc., can solve the problems of weakening of extrusion deformation and deformation of embossed patterns, etc., to improve wearing effect and visual effect, and overcome the pressure of printing points The effect of deforming the flower pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

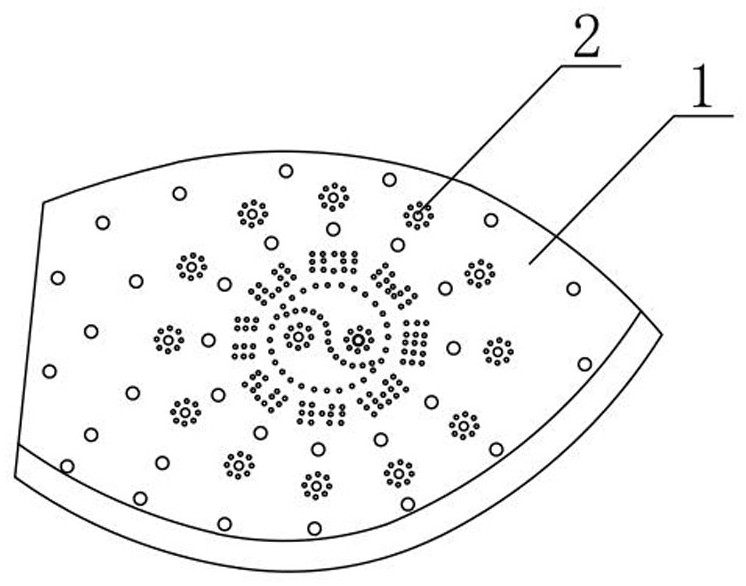

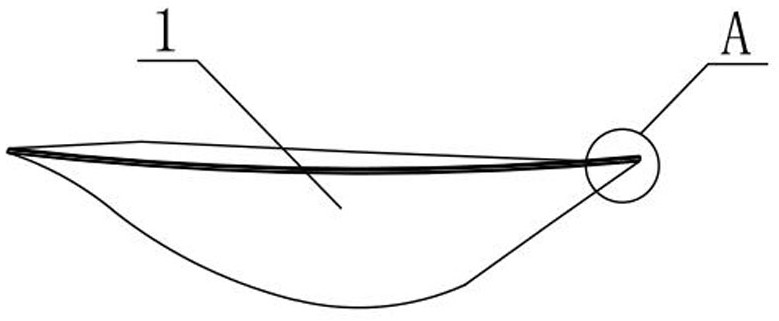

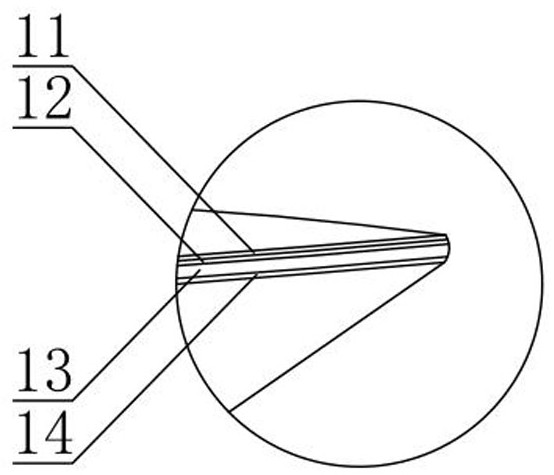

[0025] Embodiment 1: as figure 1 , figure 2 and image 3 As shown, an underwear mold cup includes a cup body 1, and the cup body 1 is composed of an inner layer of cloth 11, an inner layer of sponge 12, an outer layer of sponge 13 and an outer layer of cloth 14 in sequence, wherein the thickness of the inner layer of sponge 12 is Thinner than the thickness of the outer layer sponge 13, the exposed surface of the inner layer of cloth 11 is embossed with negative ion far-infrared coating points 2 that are patterned in a number of point layouts.

[0026] An adhesive layer is coated between the inner layer cloth 11 and the inner layer sponge 12, an adhesive layer is also coated between the inner layer sponge 12 and the outer layer sponge 13, and an adhesive layer is also coated between the outer layer sponge 13 and the outer layer cloth 14. Covered with an adhesive layer, the cup body 1 is made of an inner layer of fabric 11, an adhesive layer, an inner layer of sponge 12, an a...

Embodiment 2

[0028] Embodiment 2: the thickness range of the inner layer sponge 12 is 3 mm, and the thickness range of the outer layer sponge 13 is 10 mm.

[0029] All the other are with embodiment 1.

Embodiment 3

[0030] Embodiment 3: the thickness range of the inner layer sponge 12 is 4 mm, and the thickness range of the outer layer sponge 13 is 12 mm.

[0031] All the other are with embodiment 1.

[0032] A non-deformable compression molding process of three-dimensional printed dot embossed graphics on the inner layer of an underwear mold cup, comprising the following steps:

[0033] (1) Cutting piece preparation: cut out the inner layer fabric, inner layer sponge, outer layer sponge and outer layer fabric of the same size; A pair of symmetrically arranged mold cup holes are arranged, that is, a pair of underwear mold cups are molded together on the left and right sides.

[0034] Add a positioning structure between the two, add a pair of symmetrically arranged positioning pins in the upper mold, and add a pair of symmetrically arranged positioning holes in the lower mold, and the two positioning pins are matched with the positioning holes one by one.

[0035] (2) Primary compounding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com