Engine heat management system and charging vehicle comprising same

A thermal management system and engine technology, used in engine cooling, engine components, machines/engines, etc., can solve problems such as engine derating, over-temperature warning, and inability to work, so as to improve performance and efficiency and prolong service life. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

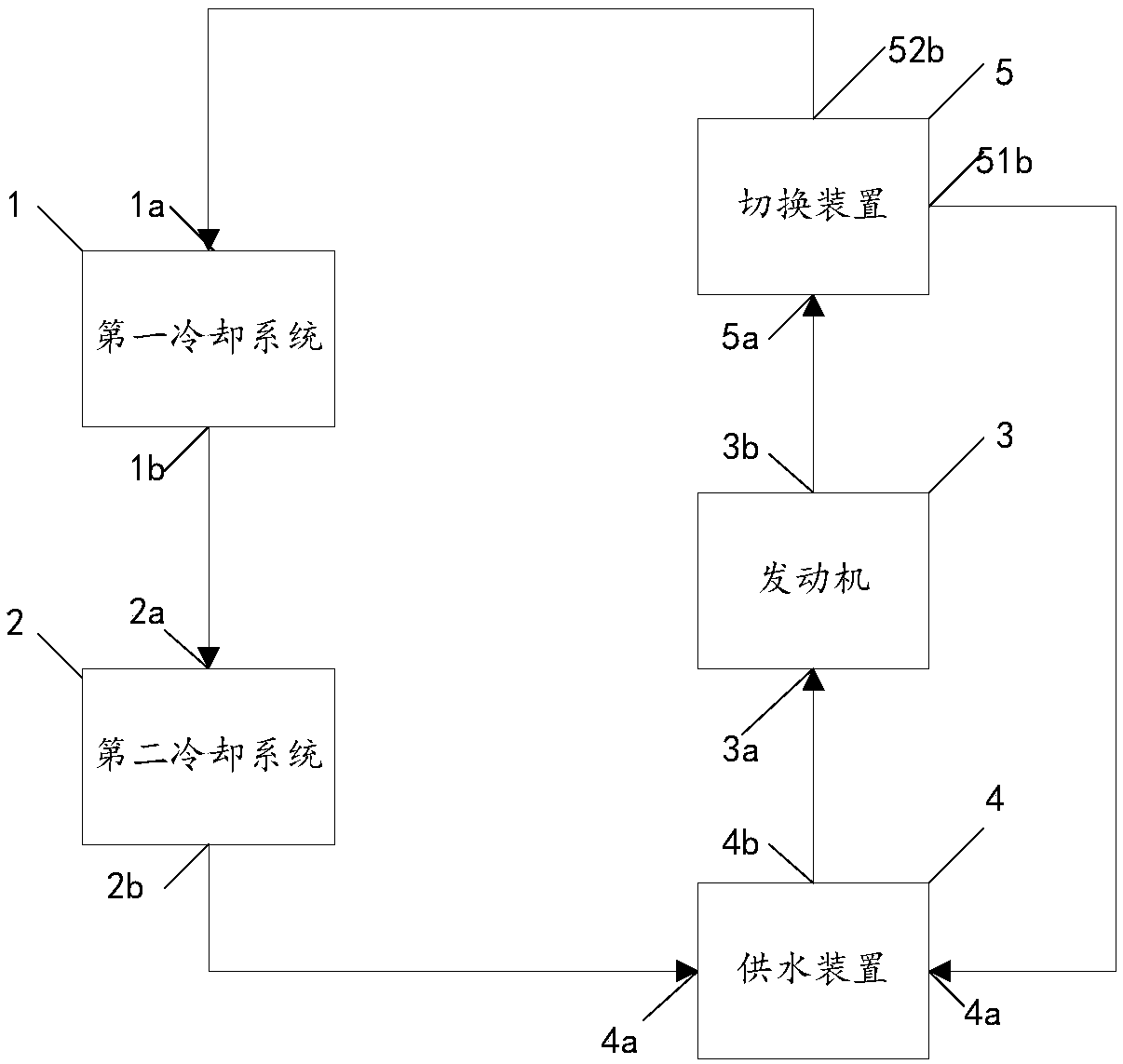

[0060] Such as figure 1 As shown, the cooling circuit comprises a first cooling system 1 and a second cooling system 2 connected in series. The second liquid outlet 52b of the switching device 5 is connected with the liquid inlet 1a of the first cooling system, and the liquid outlet 1b of the first cooling system is connected with the liquid inlet 2a of the second cooling system. The liquid outlet 2b is connected to the liquid inlet 4a of the water supply device, and the engine 3, the switching device 5, the water supply device 4, the first cooling system 1 and the second cooling system 2 form a cooling cycle.

[0061] During normal driving of the charging car, figure 1 The engine thermal management system shown does not change the control strategy of the original cooling system of the vehicle, and closes the cooling devices in the second cooling system 2, such as water pumps, fans, radiators, etc., so that the second cooling system 2 only provides coolant circulation effect...

Embodiment 2

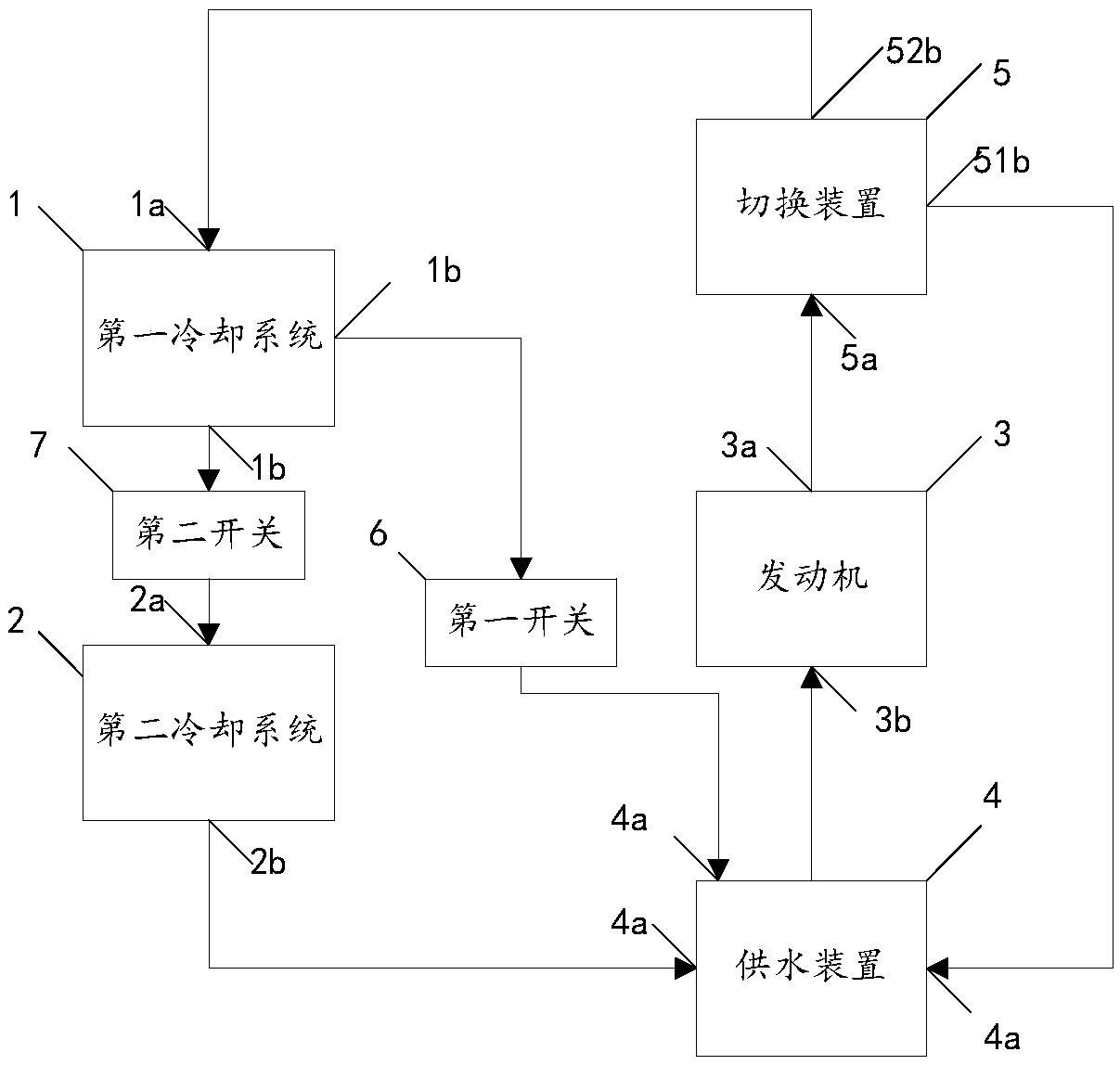

[0064] The first cooling system 1 and the second cooling system 2 are connected in series to the cooling circuit. During the normal driving of the charging car, the second cooling system 2 only provides the circulation of cooling liquid, but the cooling liquid flows through the second cooling system 2 There will still be a certain temperature change. When the temperature change range is small, it will not affect the cooling circuit during the normal driving of the charging car, but when the changing range is large, it will affect the cooling circuit during the normal driving of the charging car. affect the operation of the engine 3, thereby affecting the temperature control of the engine 3. As a modification of the embodiment, such as figure 2 The engine thermal management system shown can effectively avoid the occurrence of the above situation. The cooling circuit of the engine thermal management system also includes a first switch 6 and a second switch 7, and the first swit...

Embodiment 3

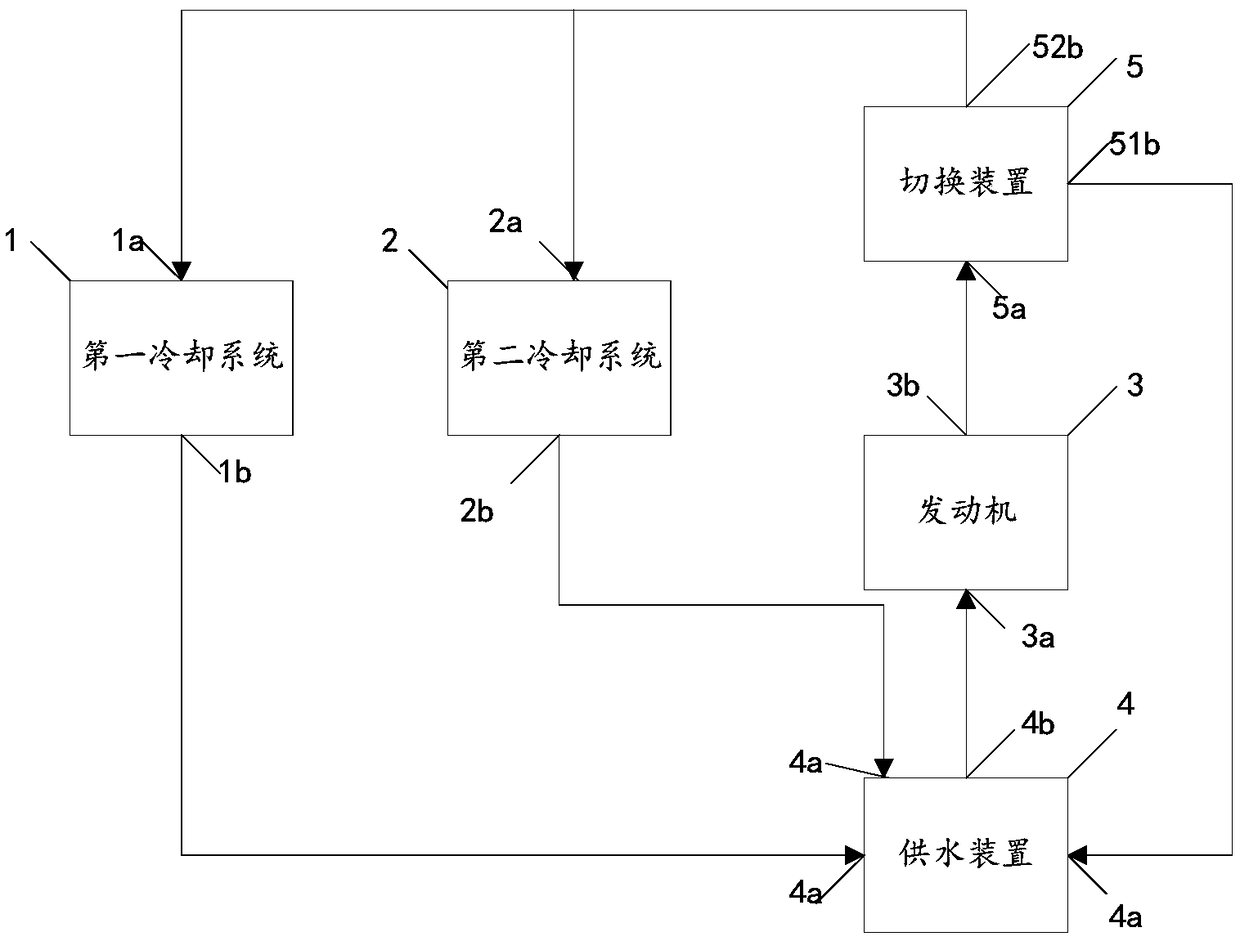

[0068] Such as image 3 As shown, the cooling circuit comprises a first cooling system 1 and a second cooling system 2 connected in parallel. The second liquid outlet 52b of the switching device 5 is connected with the liquid inlet 1a of the first cooling system and the liquid inlet 2a of the second cooling system respectively, and the liquid outlet 1b of the first cooling system and the outlet of the second cooling system The liquid ports 2b are respectively connected to the liquid inlets 4a of the water supply device, and the engine 3, the switching device 5, the water supply device 4, the first cooling system 1 and the second cooling system 2 constitute a cooling cycle.

[0069] During normal driving of the charging car, image 3 The engine thermal management system shown, without changing the control strategy of the original cooling system of the vehicle, closes the cooling devices in the second cooling system 2, such as water pumps, fans, radiators, etc., so that the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com