Scroll compressor for a vehicle air-conditioning system

A scroll compressor, compressor housing technology, applied in rotary piston machines, components of pumping devices for elastic fluids, manufacturing tools, etc., can solve the problem of unbalanced force/torque volume, reduce Problems such as wall thickness at the end section can save cutting costs, improve efficiency, and improve machine acoustics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

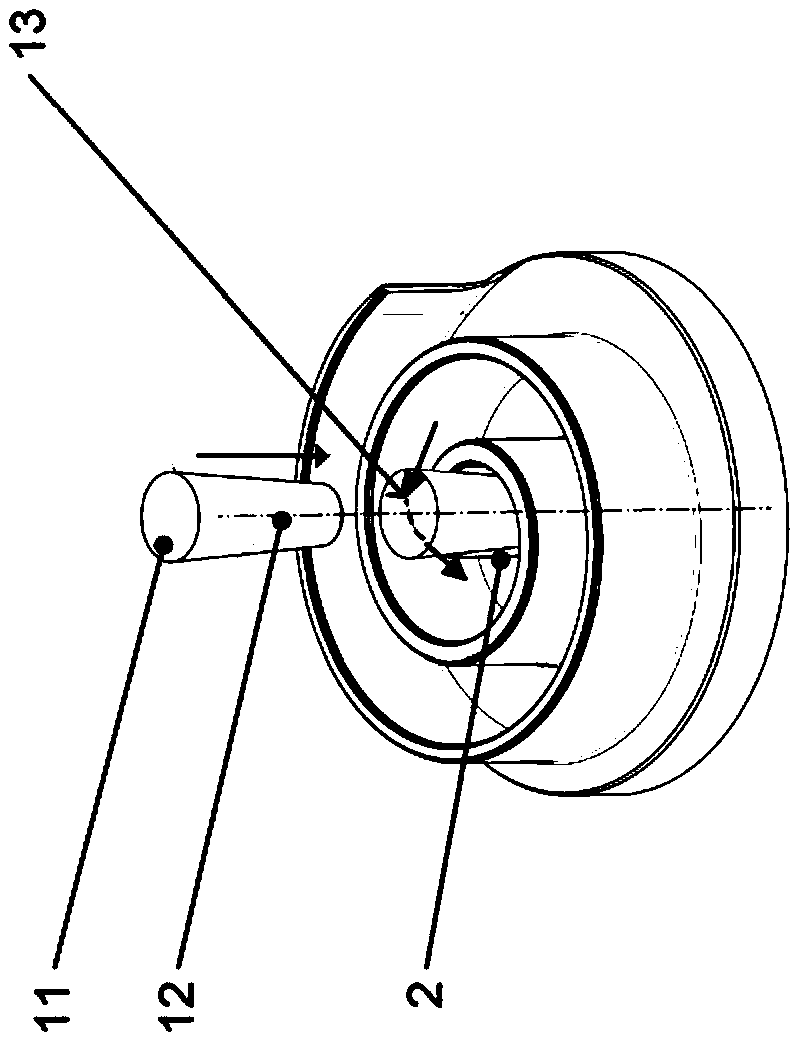

[0028] Figure 1A Shows the spiral of a scroll compressor with a prismatically cut shape according to the prior art. The illustrated spiral has vertical, so-called prismatic, chamfers in the region of the spiral ends. The wall thickness is significantly smaller in the region of the ends of the helix than in the region of the remaining helix.

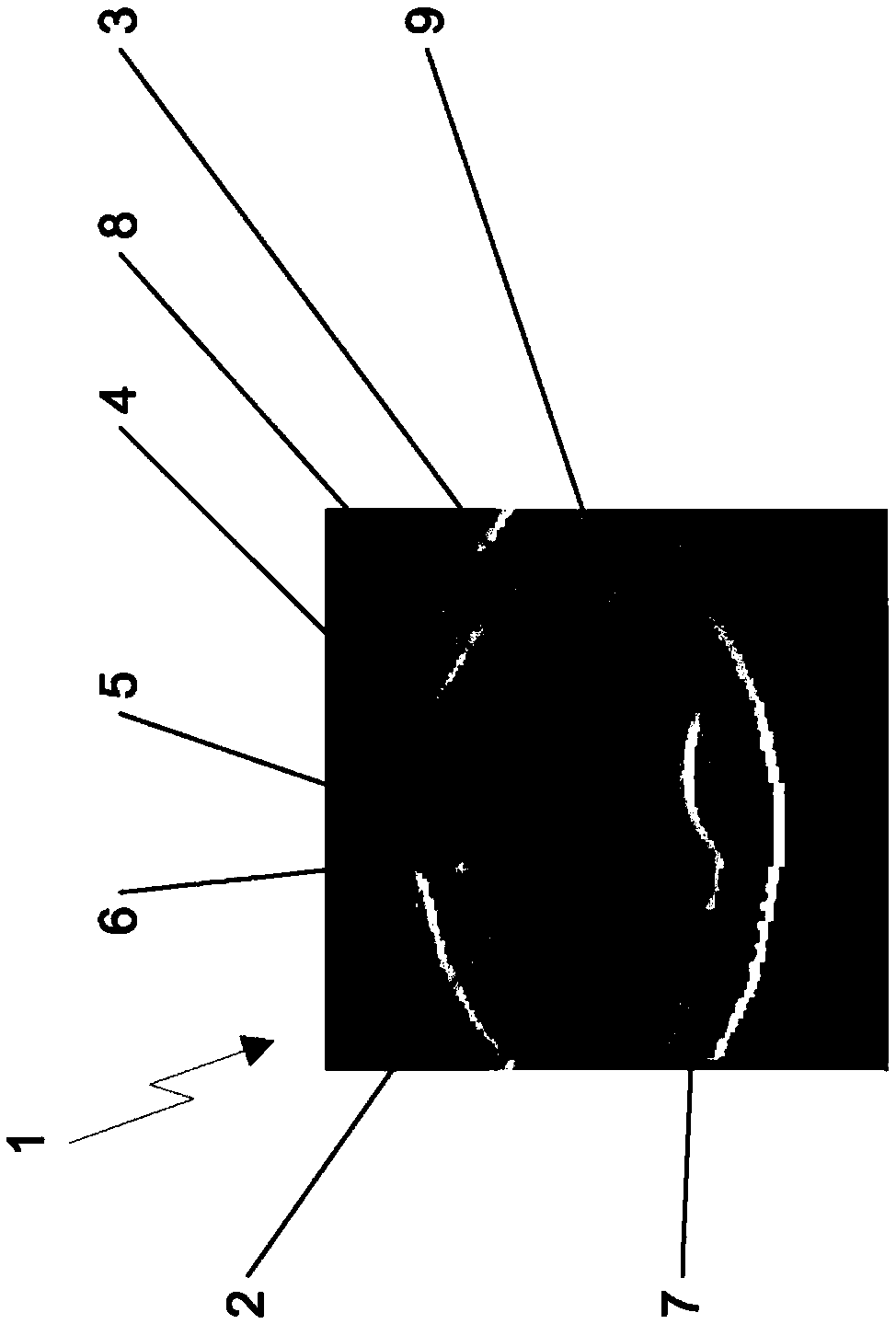

[0029] Figure 1B An embodiment of a screw 1 constructed according to the invention of a scroll compressor is shown, more precisely its screw end region. In the region of the spiral end, on the inner end 2 of the spiral 1 , the concave side 3 of the spiral wall is provided with a chamfer 4 which has the shape of a concavely curved surface of a conical section. Due to the conical shape of the chamfer 4 , an oblique edge 5 is obtained at the inner end 2 of the spiral 1 , wherein the oblique edge 5 extends over the entire height of the spiral wall. Thus, the volume of the chamfer 4 is distributed according to the inclined shape of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com