Turbulent-laminar-flow conversion device at outlet of cutting fluid circulating pool

A technology of conversion device and circulation pool, which is applied in the direction of fluid flow, metal processing machinery parts, maintenance and safety accessories, etc., and can solve problems such as wear, deterioration and odor of cutting fluid, mechanical abrasion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

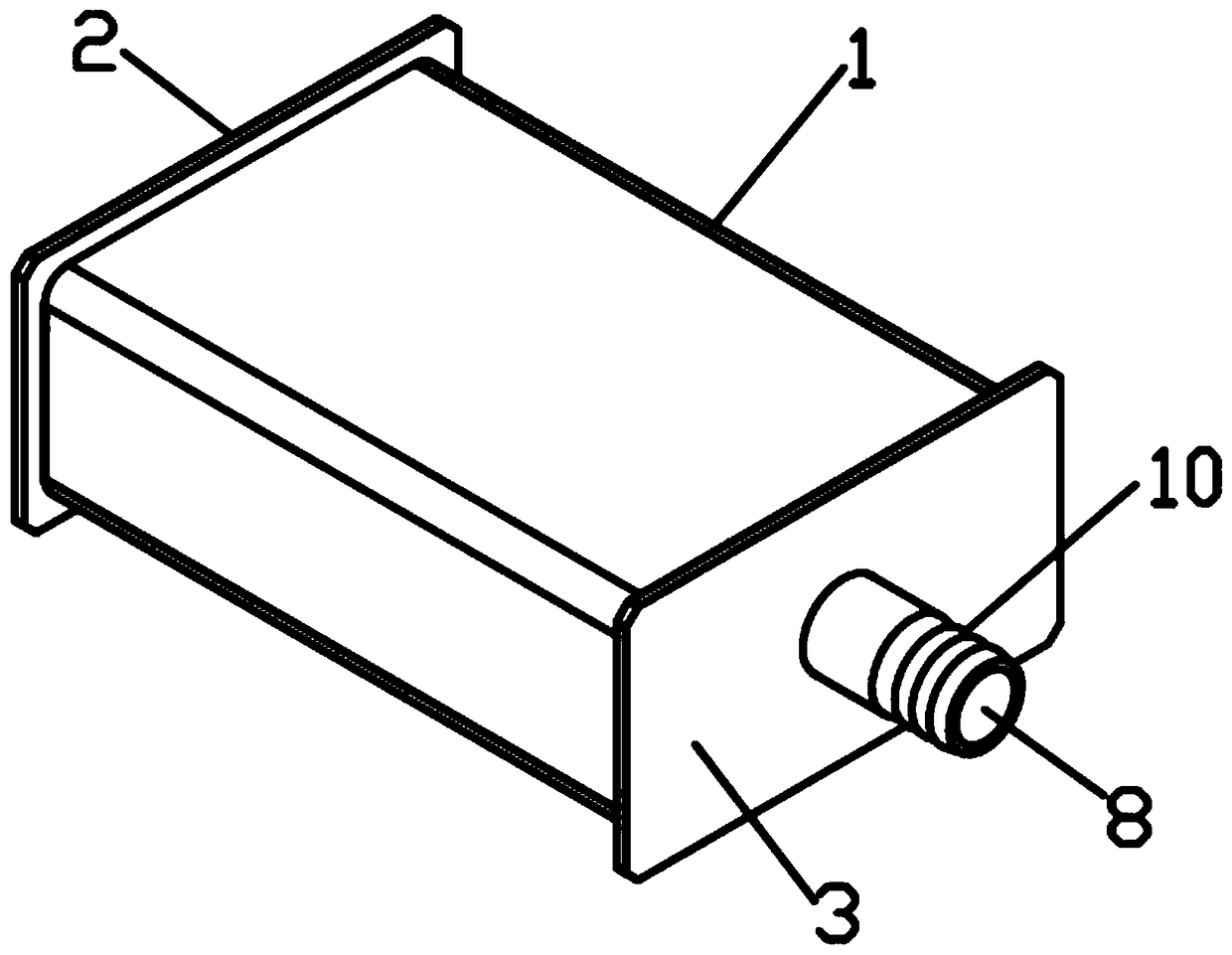

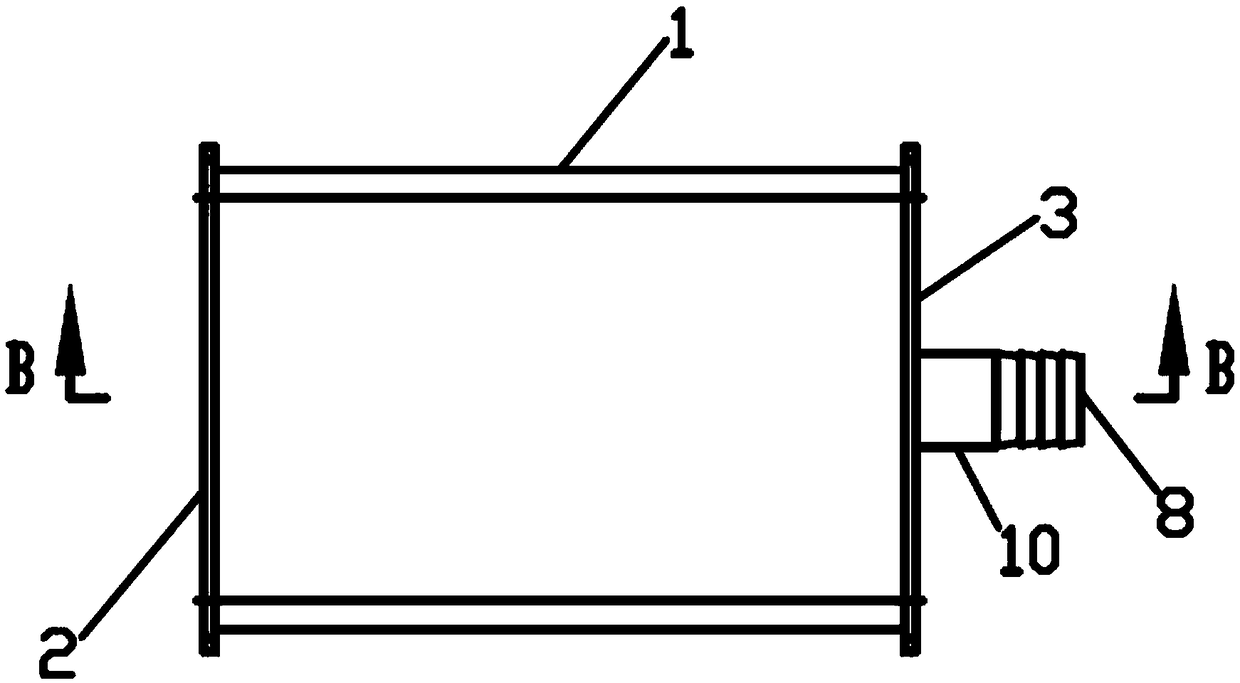

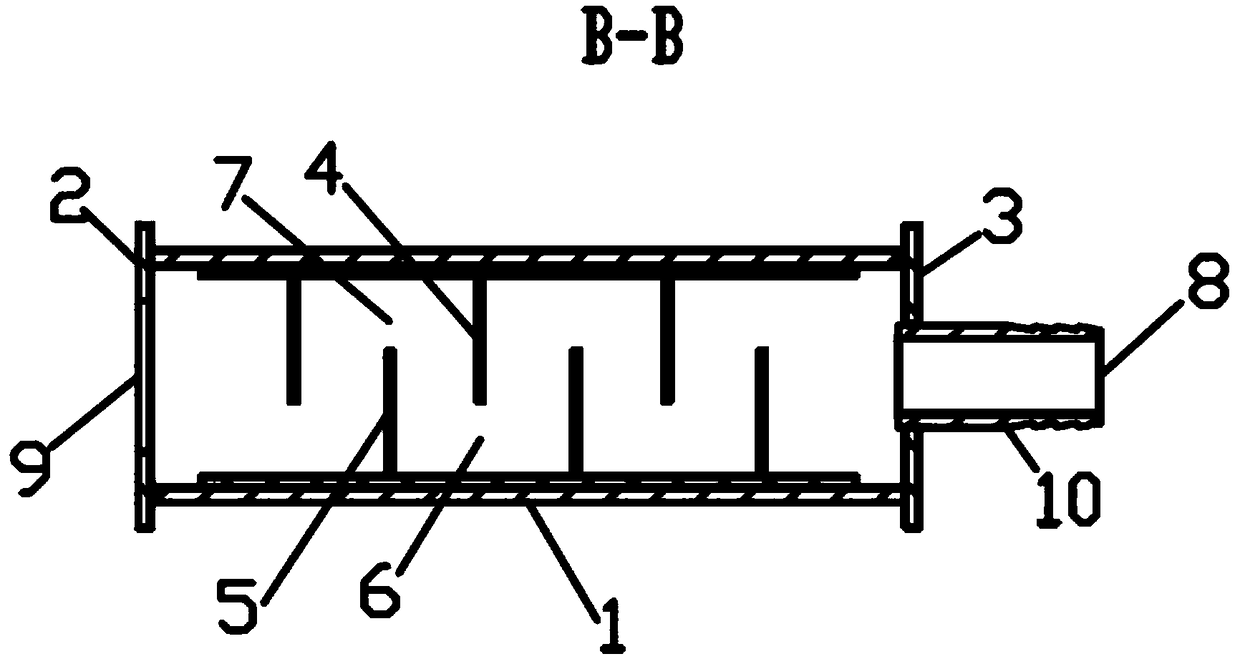

[0036] Depend on Figure 1-3 As can be seen from the illustrated embodiment, this embodiment includes a rectangular tube 1, a liquid outlet 9, a liquid inlet 8, a set of downward flow damping sheets 4 and a set of upward flow damping sheets 5, and the inner chamber of the rectangular pipe 1 The length is more than three times its height, the width value of the inner cavity section of the rectangular tube 1 > the height value of the inner cavity section of the rectangular tube 1, the liquid outlet 9 is set at the front end of the rectangular tube 1, and the liquid inlet 8 is set at the rectangular tube 1 The rear end, the cross-sectional area of the liquid outlet 9 is more than three times the cross-sectional area of the liquid inlet 8, and each downward guide damping plate 4 and each upward guide damping plate 5 are alternately ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com