Nut adjusting structure

A technology for adjusting nuts and adjusting frames, applied in the directions of nuts, screws, bolts, etc., can solve the problems of large vibration amplitude of the machine, affect the progress efficiency, and be dangerous, and achieve the effect of saving resources, avoiding failures and safety hazards, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

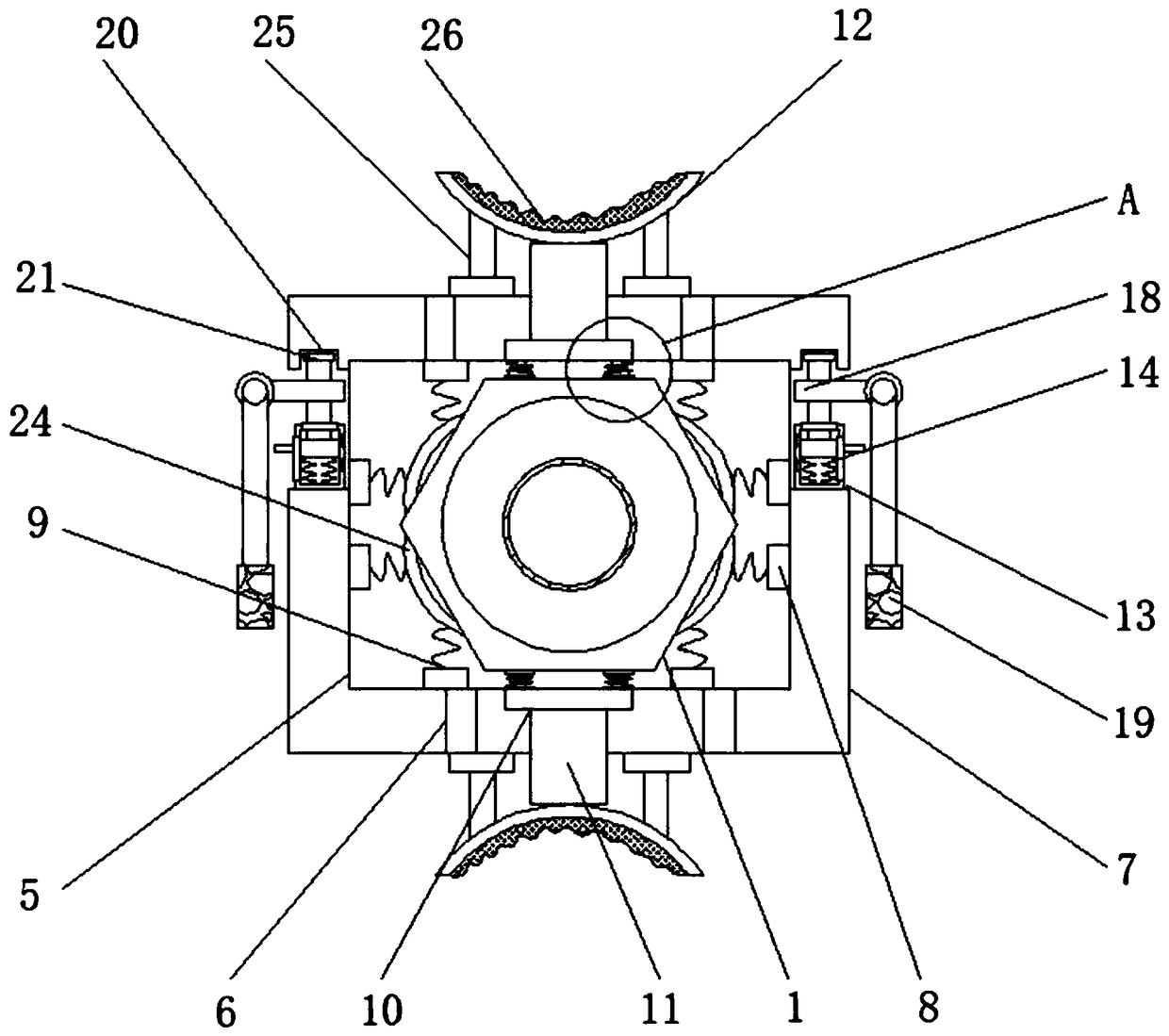

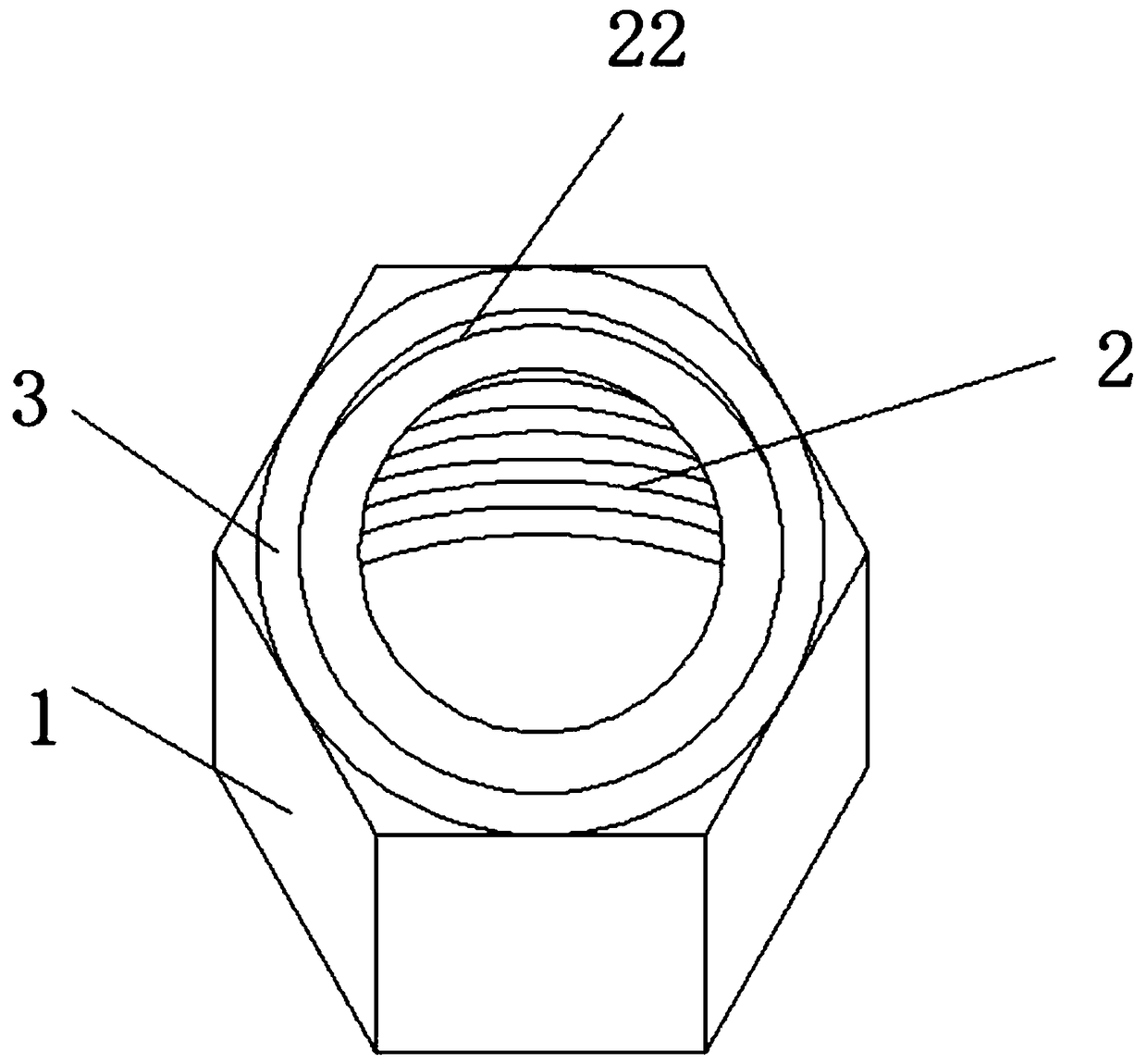

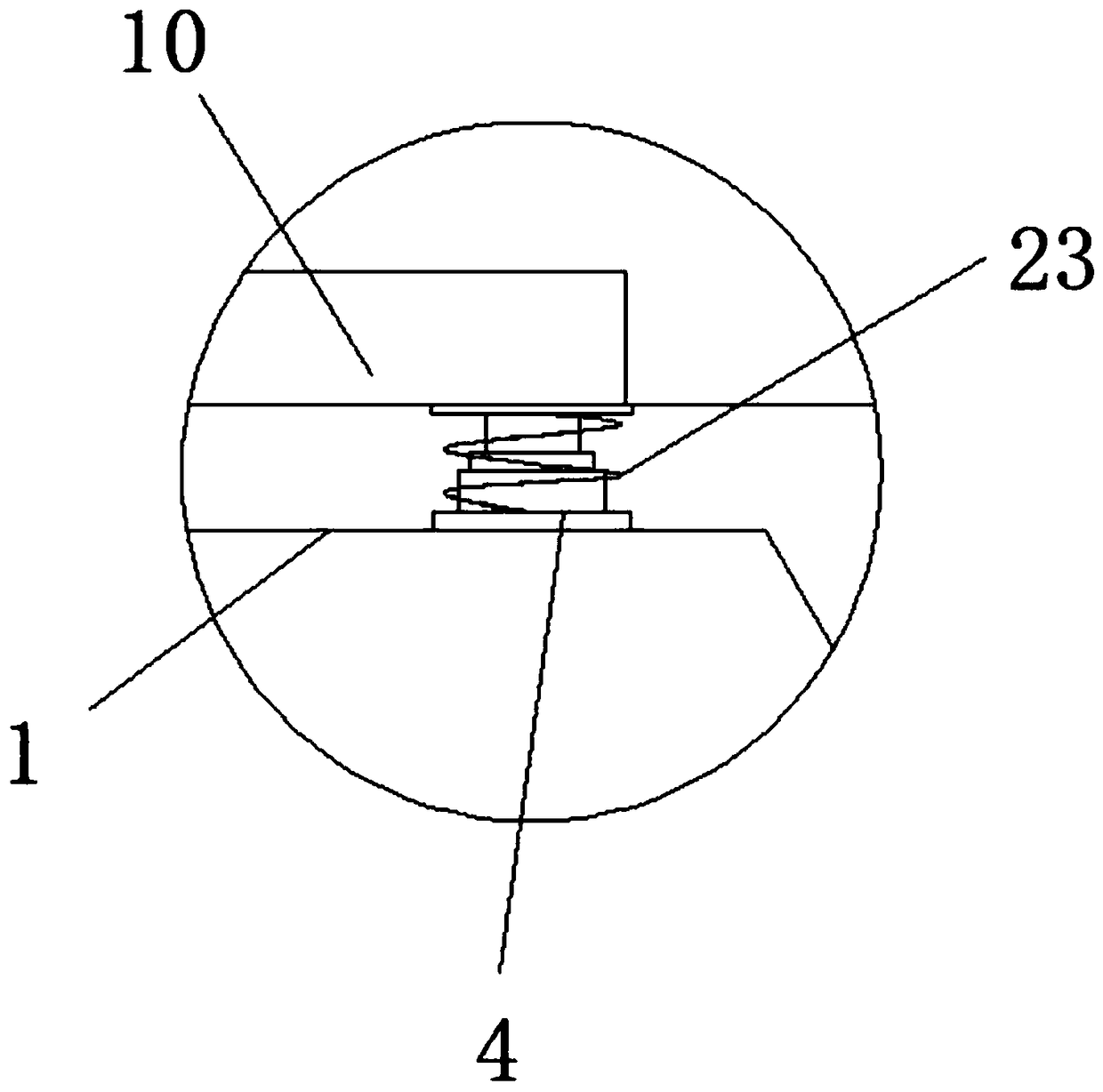

[0021] Such as Figure 1-Figure 4 As shown, an adjusting nut structure proposed by the present invention includes a body 1, the inner surface of the body 1 is provided with a rotating thread 2, the top of the body 1 is fixedly connected with a welding ring 3, and the inner surface of the welding ring 3 is provided with a rotating thread 22 , use the double screw rotation of the rotating thread 2 and the rotating thread 22 to enhance the stability, the two sides of the top and bottom of the body 1 are fixedly connected with the telescopic rod 4, and the end of the telescopic rod 4 away from the body 1 is fixedly connected with a square frame 5, Between one side of the square frame 5 and the top and bottom of the body 1 and on the surface of the telescopic rod 4, a telescopic spring 23 is sleeved, and the telescopic spring 23 on the surface of the telescopic rod 4 is used to buffer between the body 1 and the square frame 5 , the inner surface of the square frame 5 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com