Damping device for mechanical equipment

A technology of shock absorbing devices and mechanical equipment, which is applied in the direction of mechanical equipment, shock absorbers, springs/shock absorbers, etc., and can solve problems such as poor protection of shock absorbing mechanisms, mechanical equipment damage, and poor buffer protection effects , to achieve good protection effect, reduce lateral impact force and avoid misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

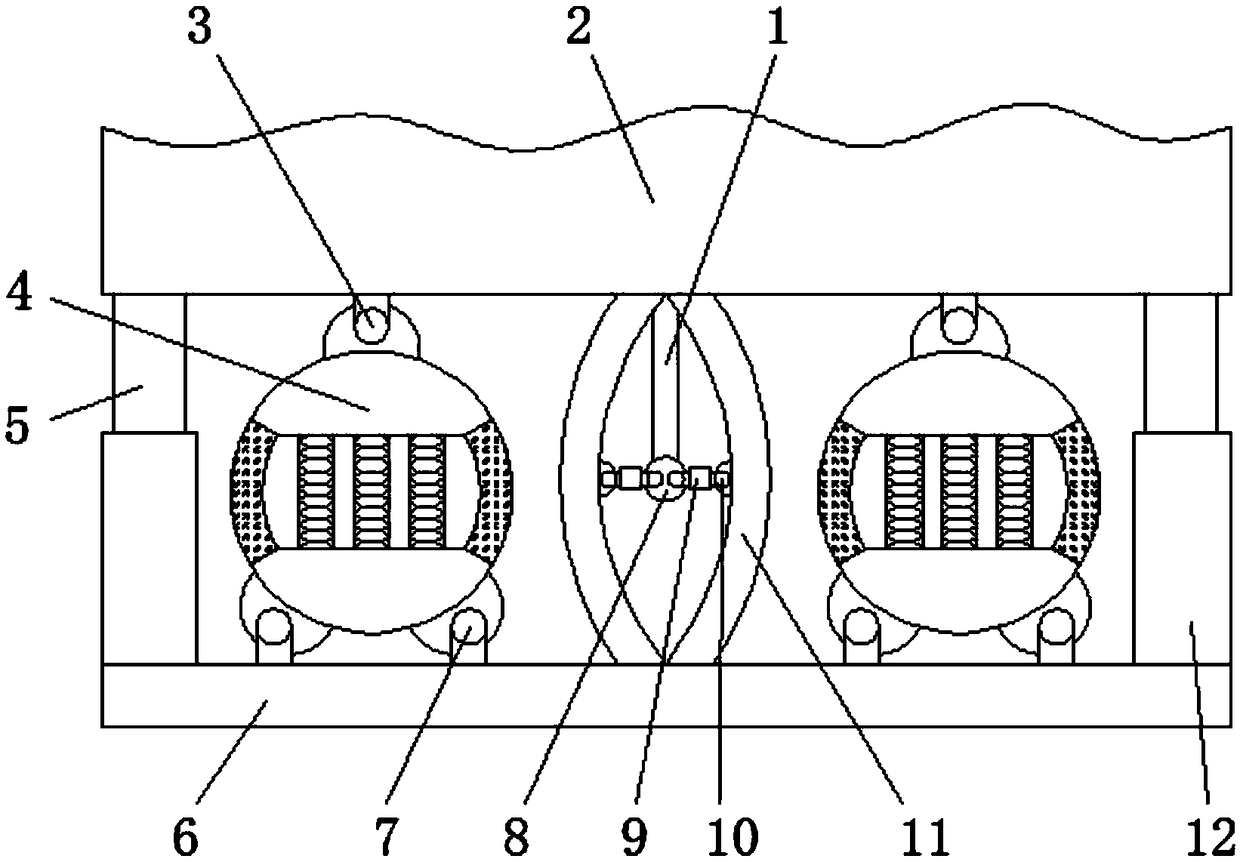

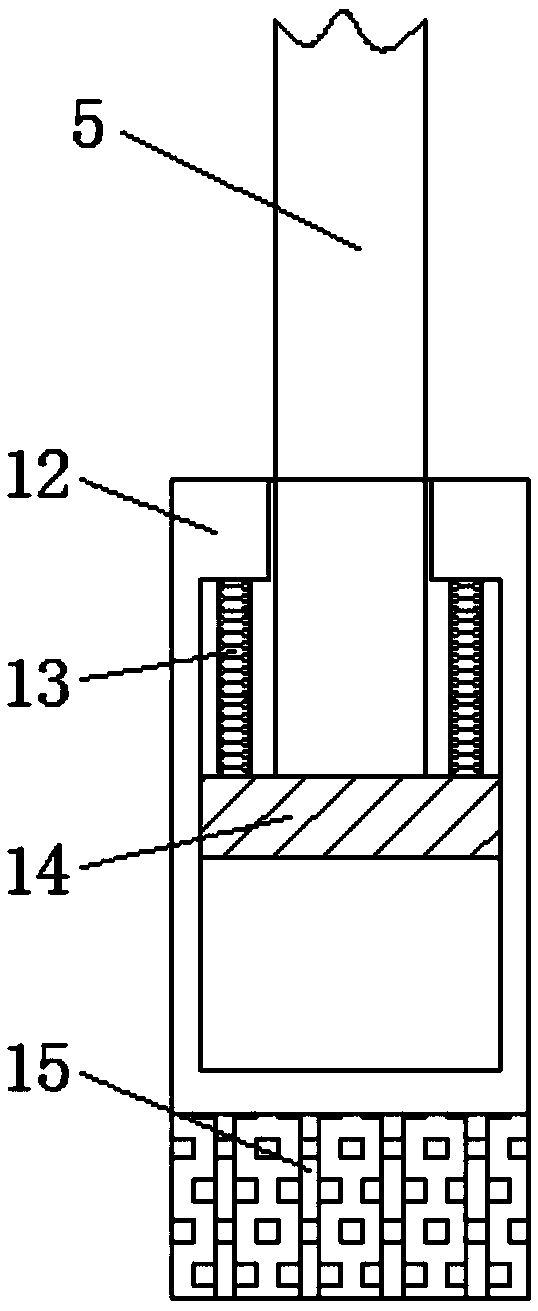

[0025] Embodiment one: refer to Figure 1-3 , a shock-absorbing device for mechanical equipment, including an upper fixing seat 2 and a lower fixing seat 6, the four corners of the top of the lower fixing seat 6 are welded with fixed sleeves 12, and the bottom of the fixed sleeve 12 is provided with a SH180X1480 hydraulic cylinder 15. The inside of the fixed sleeve 12 is covered with a sealing plate 14, the top of the sealing plate 14 is welded to the upper fixing seat 2 through the connecting rod 5 passing through the fixing sleeve 12, and the middle position of the top of the lower fixing seat 6 is symmetrically arranged. The arc-shaped elastic plate 11 is connected with the upper fixing seat 2, and the bottom of the upper fixing seat 2 is located at the intersection of the two arc-shaped elastic plates 11 and is connected with a fixed disc 8 through the fixing rod 1, wherein the center line of the two arc-shaped elastic plates 11 On the same level as the fixed disk 8, the f...

Embodiment 2

[0026] Embodiment two: refer to figure 2 The outer side of the connecting rod 5 on the sealing plate 14 is elastically connected to the top of the fixed sleeve 12 through a plurality of first tension springs 13. This structure can prevent the impact force received between the connecting rod 5 and the fixed sleeve 12 from being relatively large. Large, falling off occurs, and at the same time, buffer protection can be performed between the sealing plate 14 and the fixed sleeve 12 .

Embodiment 3

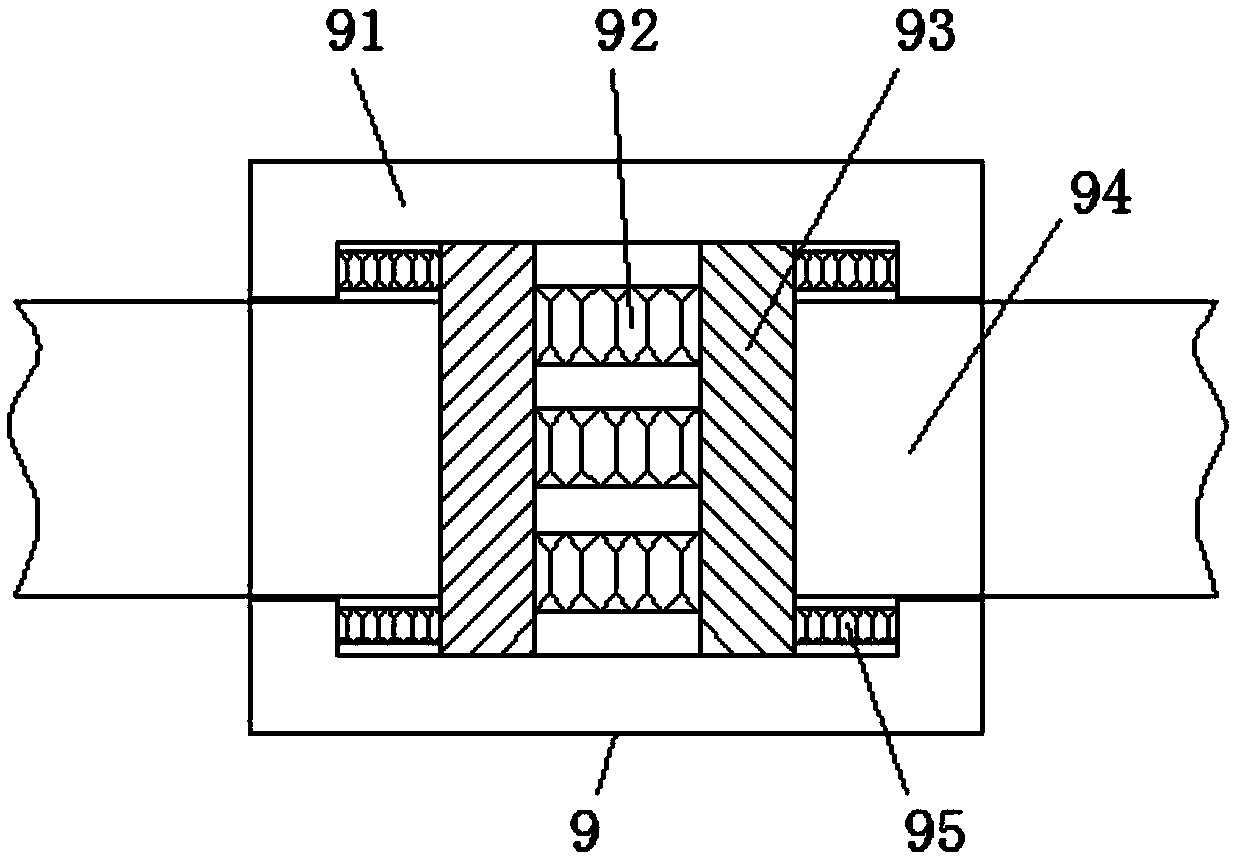

[0027] Embodiment three: refer to figure 1 with Figure 4 , the top of the lower fixing seat 6 is located on both sides of the arc-shaped elastic plate 11 and is flexibly connected with the buffer sphere 4 through the second movable connection card 7, and the top center of the buffer sphere 4 is movable with the upper fixing seat 2 through the first movable connection card 3 The connection can make the buffer sphere 4 deform in different directions, so that the effect of shock absorption is better. The inside of the buffer sphere 4 is a hollow structure, and an elastic connecting ring 42 is arranged at the middle position of the outer wall of the buffer sphere 4, and the buffer sphere The inside of 4 is connected to both ends by a buffer spring 41, and there are two second movable connection cards 7 located at the bottom of the buffer sphere 4, and the two second movable connection cards 7 are symmetrical about the vertical midline of the buffer sphere 4, and the upper fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com