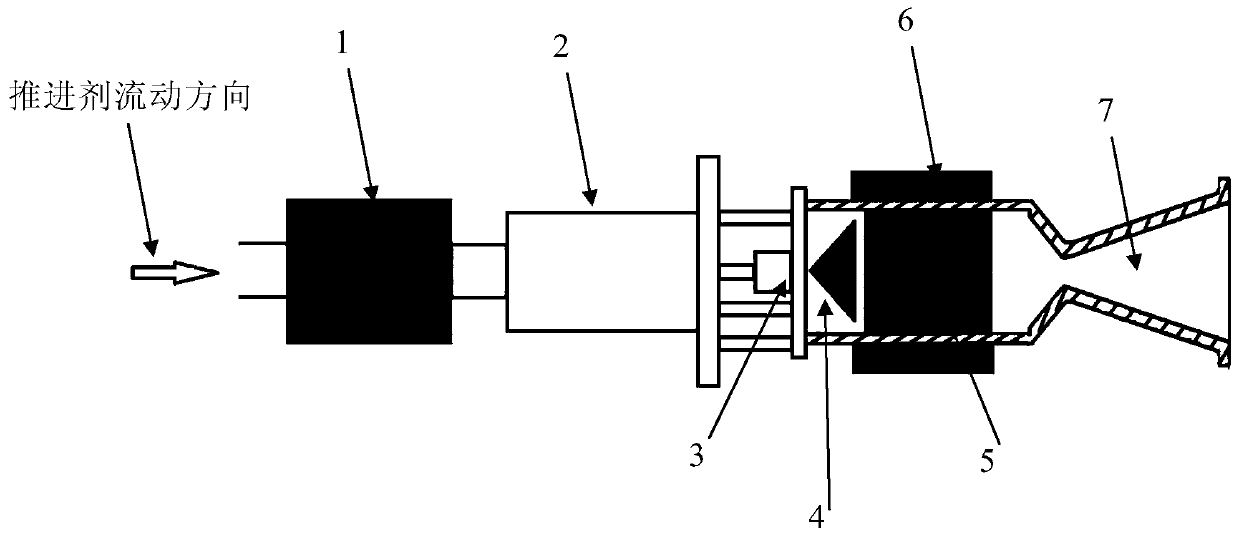

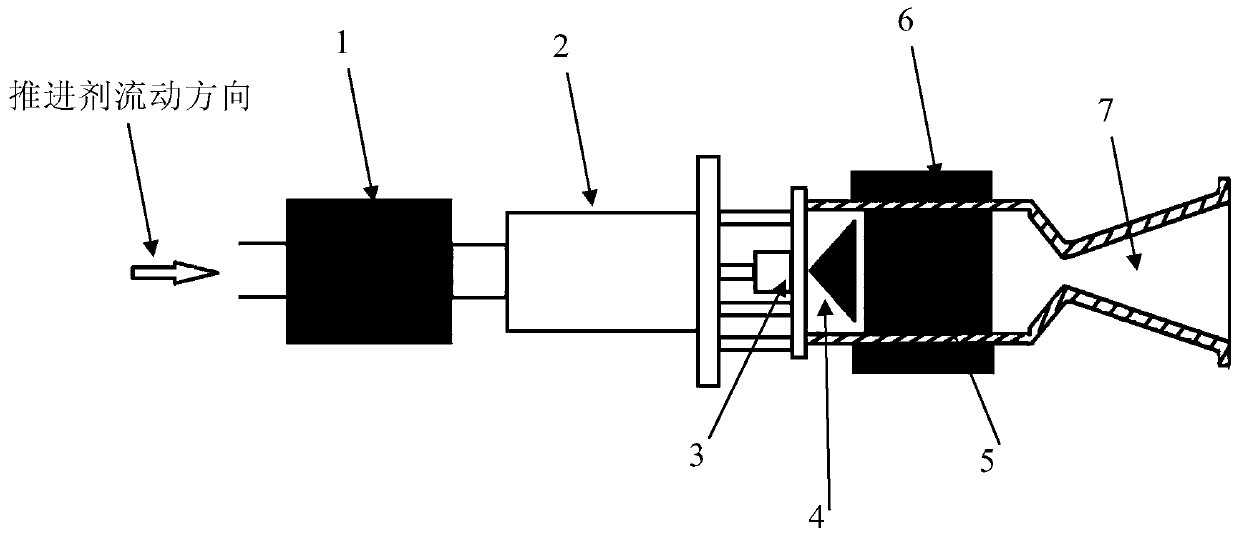

Catalytic combustion engine and combustion method for high viscosity ionic liquid propellant

A technology of liquid propellants and ionic liquids, applied in combustion methods, combustion chambers, combustion equipment, etc., can solve problems such as high viscosity of propellants, poor fluidity, lack of heating function of foam metal preheater, etc., to improve flow Performance and atomization performance, increase the effective contact area, and improve the effect of catalytic combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Implementation steps of the present invention are as follows:

[0044] Quantitative engine parameters: ionic liquid propellant main components: hydroxylammonium nitrate, 1-ethyl-3-methylimidazolium ethyl sulfate, a small amount of solvent.

[0045] Rated injection pressure of ion propellant: 1.7MPa

[0046] Rated flow of ion propellant: 3.0g / s

[0047] Catalytic bed design fuel pressure: 0.5MPa

[0048] Engine rated thrust: 5N

[0049] The longest continuous ignition time of the engine in steady state: 200s.

[0050] The implementation steps are as follows:

[0051] 1. The upstream propellant injection pressure of the metal foam preheater is 1.7MPa, and the metal foam preheater with suitable fluid resistance and porosity is selected through the rated propellant flow rate of 3.0g / s, and the power of the preheater is 10w. After the propellant flows through the metal foam preheater at a flow rate of 3.0g / s, the temperature of the propellant at the outlet of the prehea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap