Phase changing heat storing peak valley heating system and heating method thereof

A phase-change heat storage and heating system technology, which is applied in electric heating systems, heating systems, heating methods, etc., can solve the problems of phase-change heat storage and electricity peak shaving and valley filling, and achieve reduced operating costs, accurate heating efficiency, and energy saving The effect of power resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

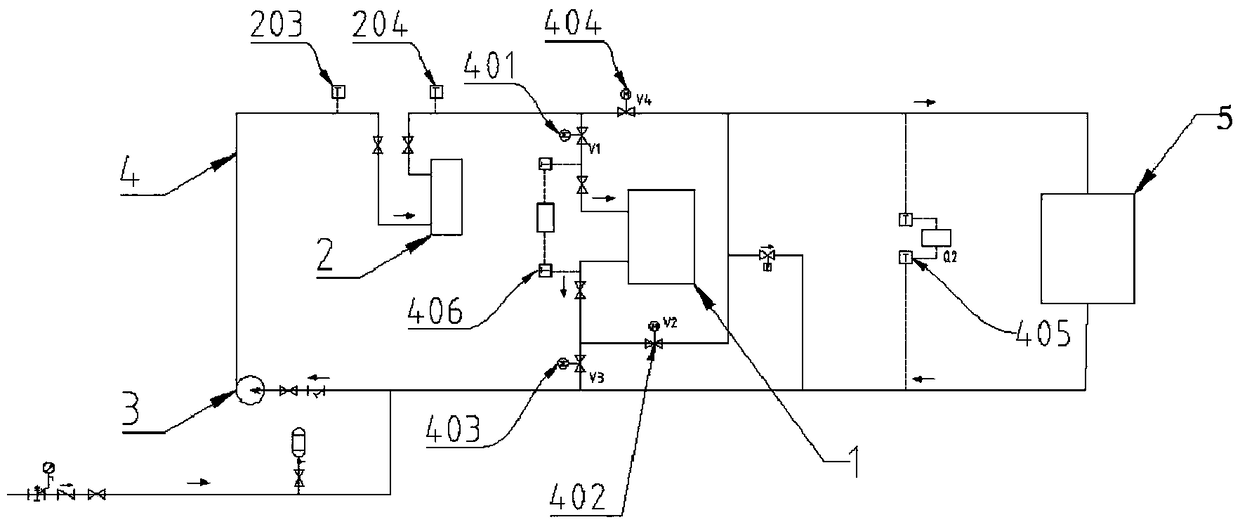

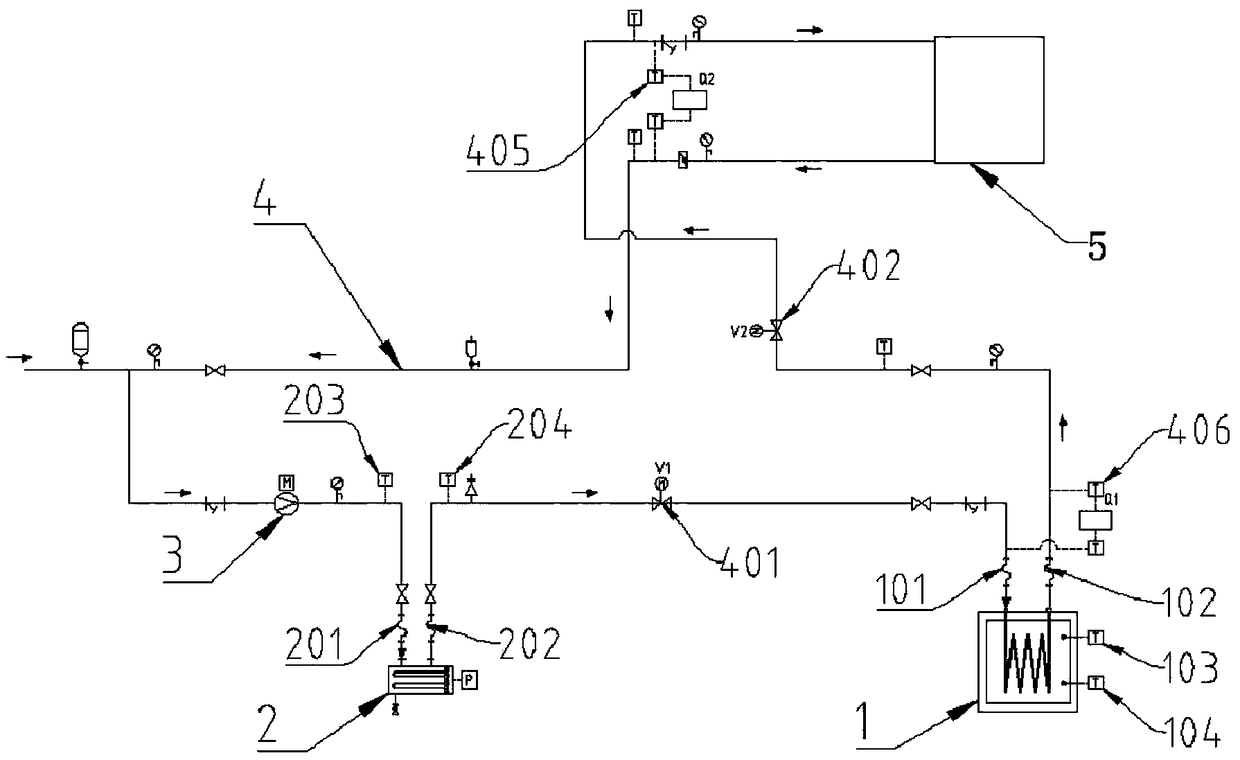

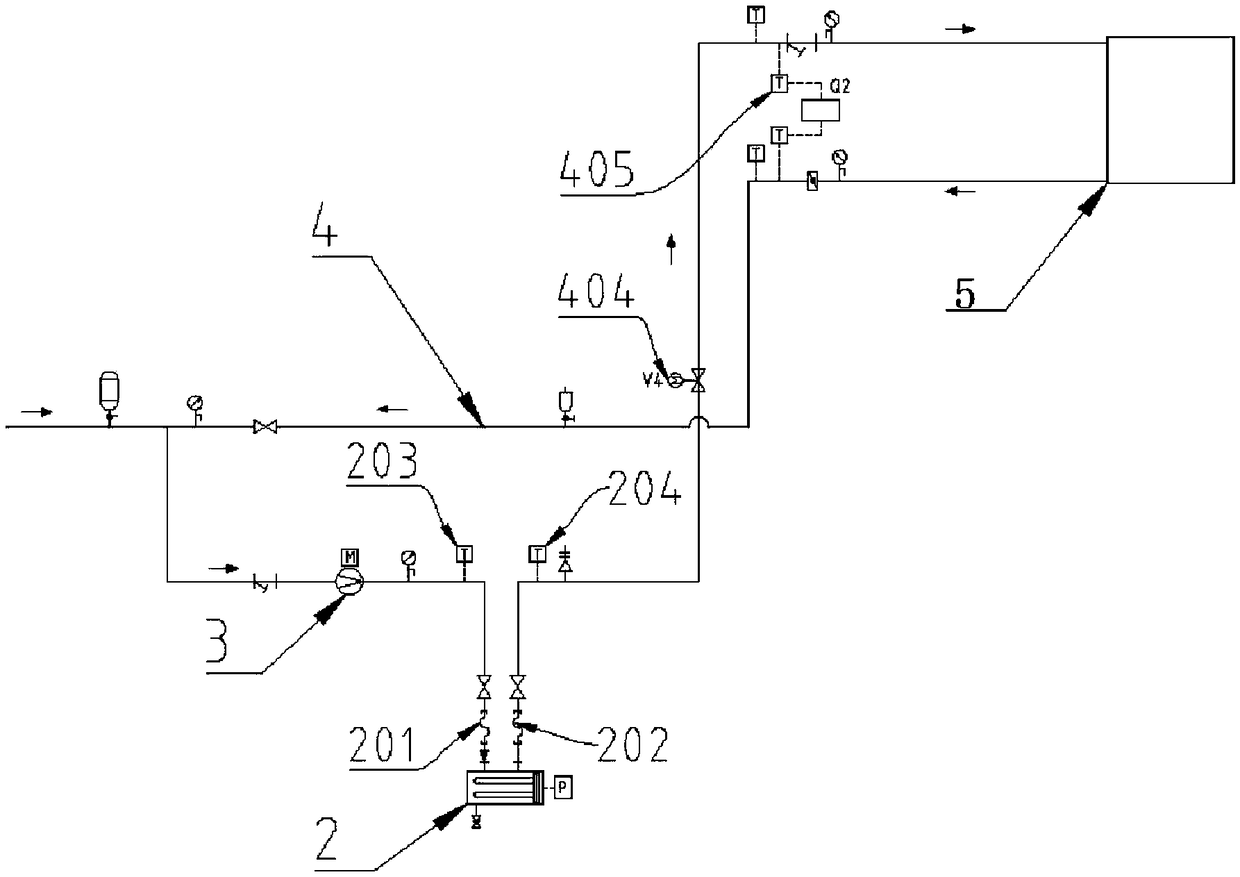

[0042] Embodiment 1: as figure 1 As shown, a phase change heat storage peak and valley heating system and method in this embodiment has a phase change heat storage device 1, an electric heating pipe 2, a circulating water pump 3, a circulating water network pipeline 4 and a heating control system. The thermal device 1 is provided with a heat storage water inlet 101 connected to the heating water outlet 202 of the electric heating tube 2, the heat storage water outlet 102 is connected to the user port 5, and the heating water inlet 201 of the electric heating tube 2 is connected to the circulating water pump 3, The circulating water network pipeline 4 is respectively provided with the electric V1 switch valve 401 of the heating water outlet 202 and the heat storage water inlet 101, the electric V2 switch valve 402 of the heat storage water outlet 102 and the user port 5, the heat storage water outlet 102 and the circulating water pump 3 electric V3 switch valve 403, heating wat...

Embodiment 2

[0067] The heating control system 6 dynamically controls the power output of the electric heating tube 2 according to the calorific value in the phase change heat storage device 1 . The existing heating system supplies heat directly from electric heating, and does not monitor the end in real time. The ultimate goal of this embodiment is to combine the temperature of the end to directly affect the temperature provided by the heating system, through the Q2 ultrasonic heat set at the user port 5 Meter 405 feeds back the user's temperature, and controls the real-time power of the electric heater 2 through comprehensive calculation.

[0068] The power regulator can control the real-time power percentage of the electric heating tube through the analog output current 4-20mA signal, that is, through the power percentage adjustment, the power control of the electric heating tube can be realized, and the stable operation of the system can be realized. In the calculation process, the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com