Energy-saving type cooling machine

A cooling machine and energy-saving technology, which is applied in the direction of refrigerators, compressors, refrigeration components, etc., can solve the problem that the cooling machine cannot meet the energy-saving demand, and achieve the effect of meeting the energy-saving demand and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

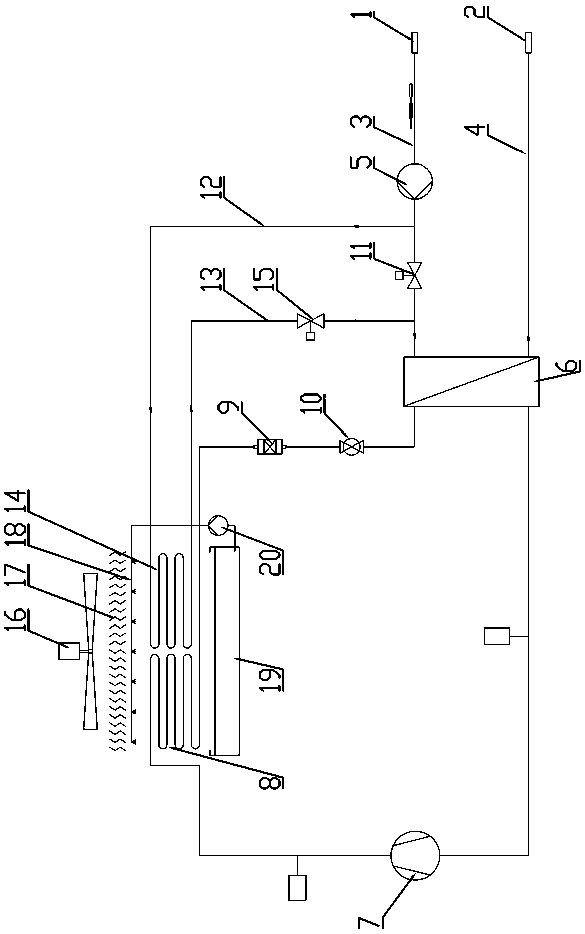

[0009] like figure 1 As shown, the energy-saving cooler includes a refrigeration system and a liquid circulation circuit. The refrigeration system includes a compressor 7, an evaporative condenser, a dry filter 9, an expansion valve 10 and an evaporator 6 connected in sequence. The refrigeration system is located in the compressor The inlet and outlet pipelines of 7 are equipped with a low-pressure pressure control switch and a high-pressure pressure control switch. The liquid circulation circuit includes a liquid input pipeline 3 and a liquid return pipeline 4. The liquid input pipeline 3 is connected to the liquid inlet 1 of the cooler and the evaporator The input end of the liquid pipeline of 6, the liquid return pipeline 4 connects the liquid outlet 2 of the cooler and the output end of the liquid pipeline of the evaporator 6, and the evaporative condenser includes a blower fan 16, a dehydrator 17, which are arranged from top to bottom. The spray pipe 18, the first condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com