Light bullet supplementing mechanism

A light-duty, plucking wheel technology, applied in ammunition supply, weapon accessories, offensive equipment, etc., can solve the problems of personnel injury, heavy mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

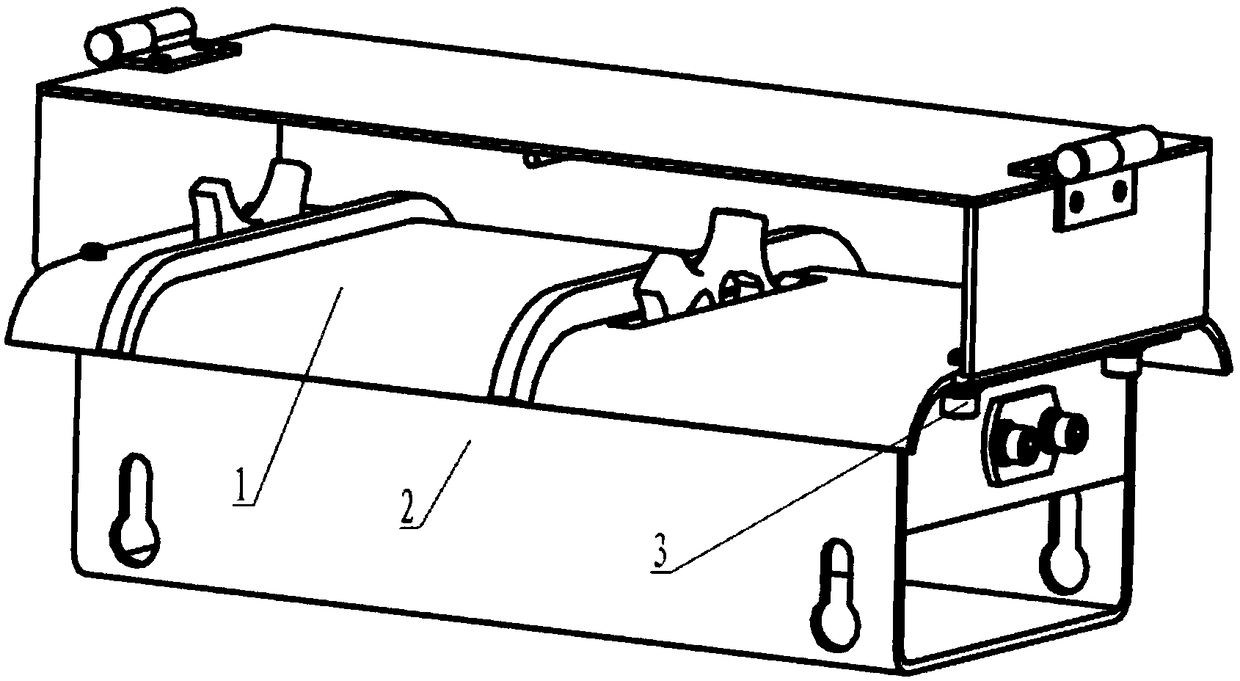

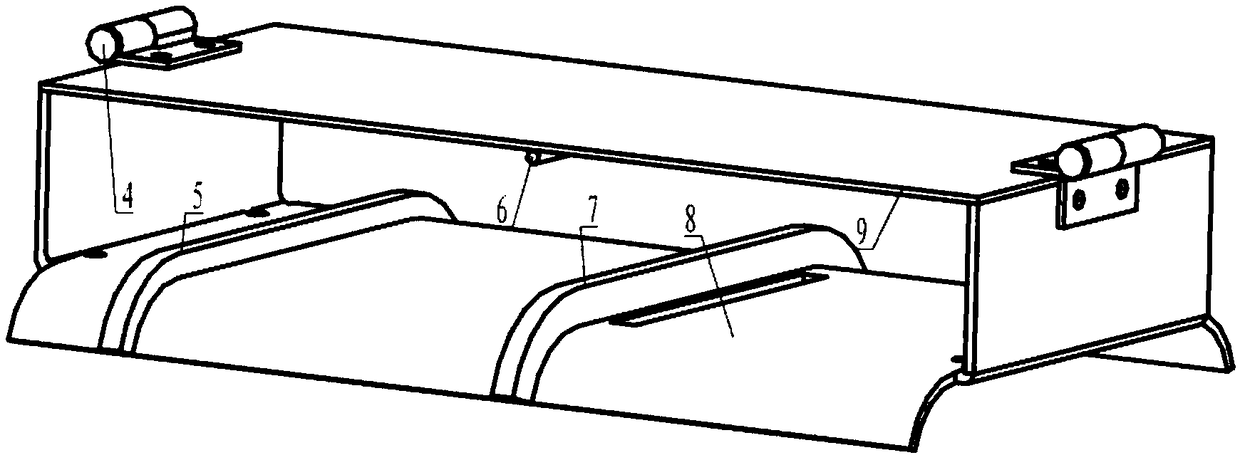

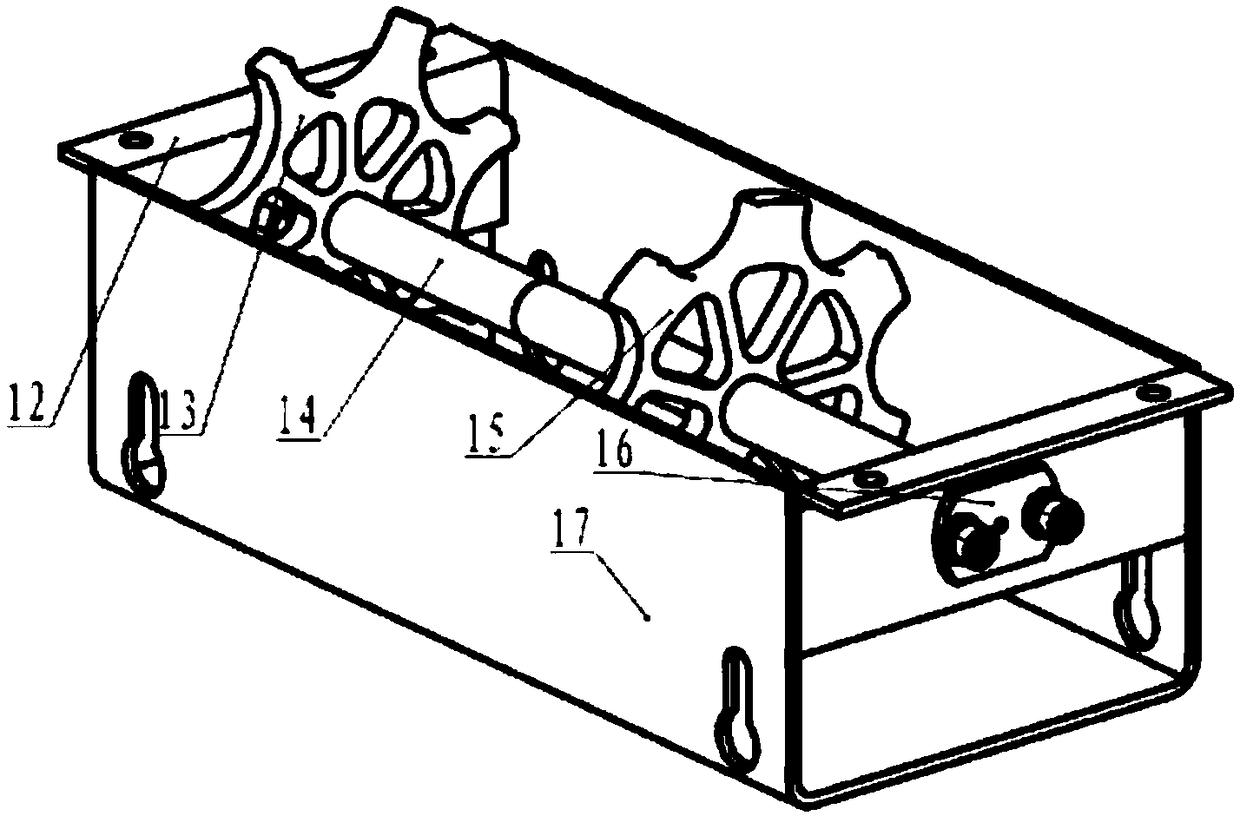

[0033] see figure 1 — Figure 16 , the technical scheme that the present invention adopts to solve its technical problem is: a kind of 30mm chain cannon ammunition replenishment mechanism, comprises refill interface mechanism 1 and dial wheel combination 2, described ammunition replenishment interface mechanism 1 and dial wheel combination 2 are threadedly connected by screws 3; the bomb feeding interface mechanism 1 includes a detachable pin 4, a thin guide bar 5, a round guide bar 6, a thick guide bar 7, a curved plate 8, and a flip cover 9; the dial combination 2 includes a shaft 10, a short Sleeve 11, connecting plate 12, large dial elastic wheel 13, sleeve pipe 14, small dial elastic wheel 15, long sleeve 16, shroud 17, key 18; described bomb filling interface mechanism makes 30 elastic chains limited to the thin guide Between the bar and the thick guide bar, by removing the pin shaft in the detachable pin, the flip cover can be opened in both directions, which is conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com