Pressure calibration and detection method for electronic pressure cooker

A detection method and pressure cooker technology, applied in the field of pressure cookers, can solve the problems of low detection accuracy and single working pressure, and achieve the effect of solving single working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

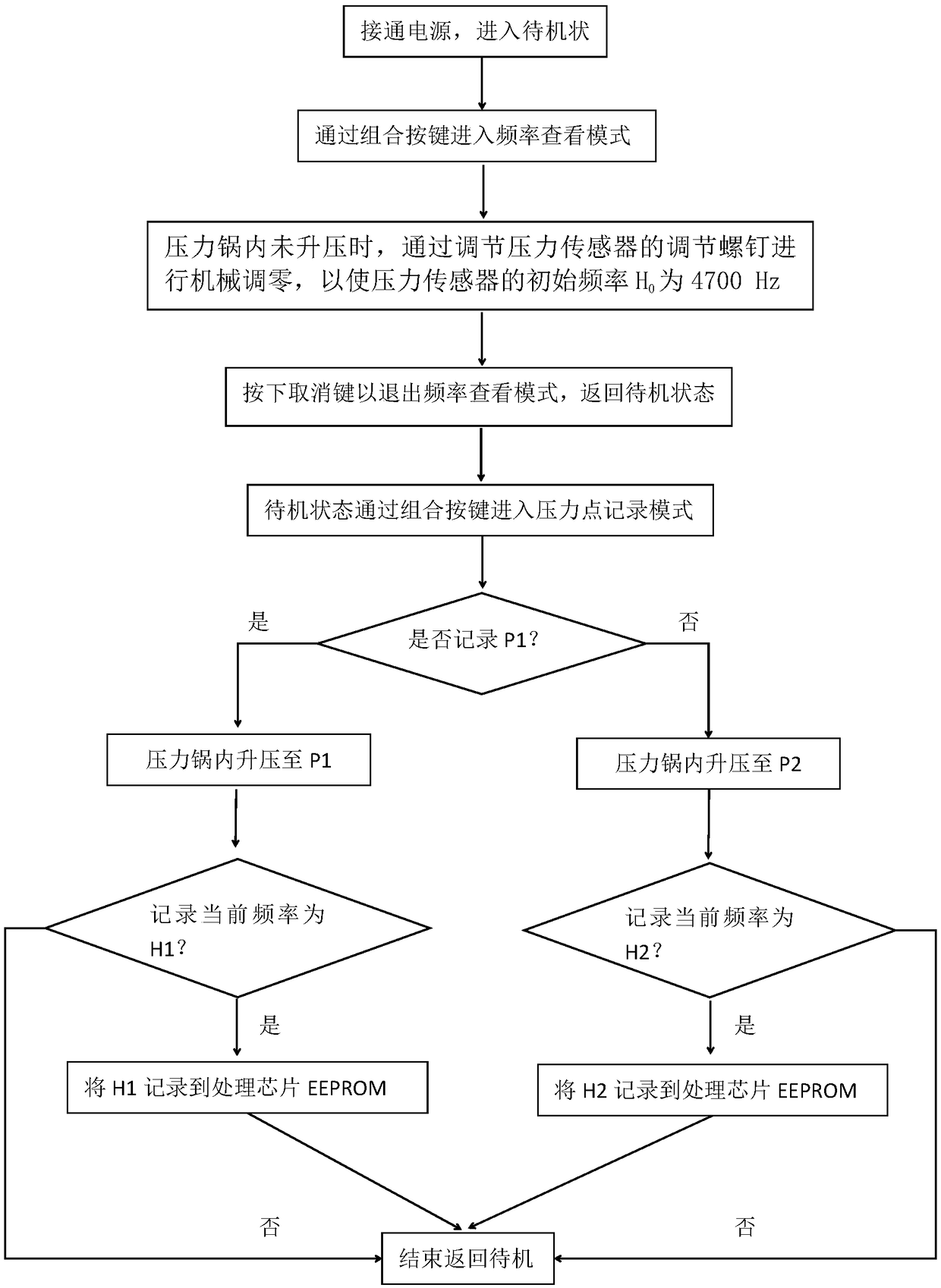

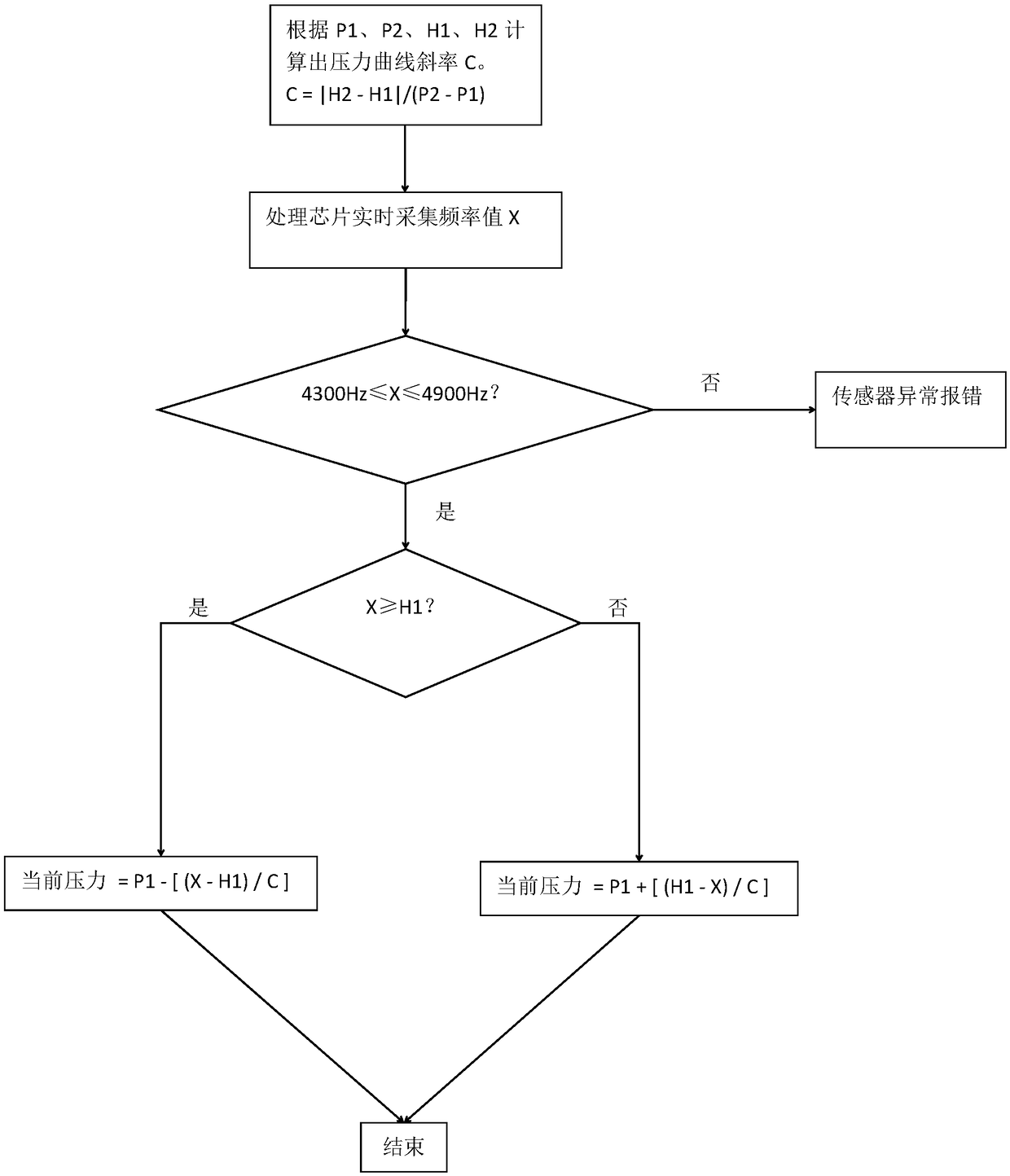

[0019] As shown in the figure, the pressure calibration and detection method of the electronic pressure cooker includes the following steps:

[0020] Step 1. First turn on the power to enter the standby state, and then enter the frequency viewing mode through the combination of buttons on the pressure cooker. Then, when the pressure in the pressure cooker is not boosted, perform mechanical zero adjustment by adjusting the adjustment screw of the pressure sensor to make the pressure sensor The initial frequency H 0 4700 Hz, then press the cancel button to exit the frequency viewing mode, and then enter the pressure point recording mode through the combination of buttons on the pressure cooker;

[0021] Step 2. When the pressure is increased in the pressure cooker, the diaphragm of the heating plate is deformed to adjust the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com