Combined test device for surface flashover and breakdown of transformer oil-paper insulation

A surface flashover, transformer oil technology, applied in the direction of measurement equipment, test ship construction, test dielectric strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

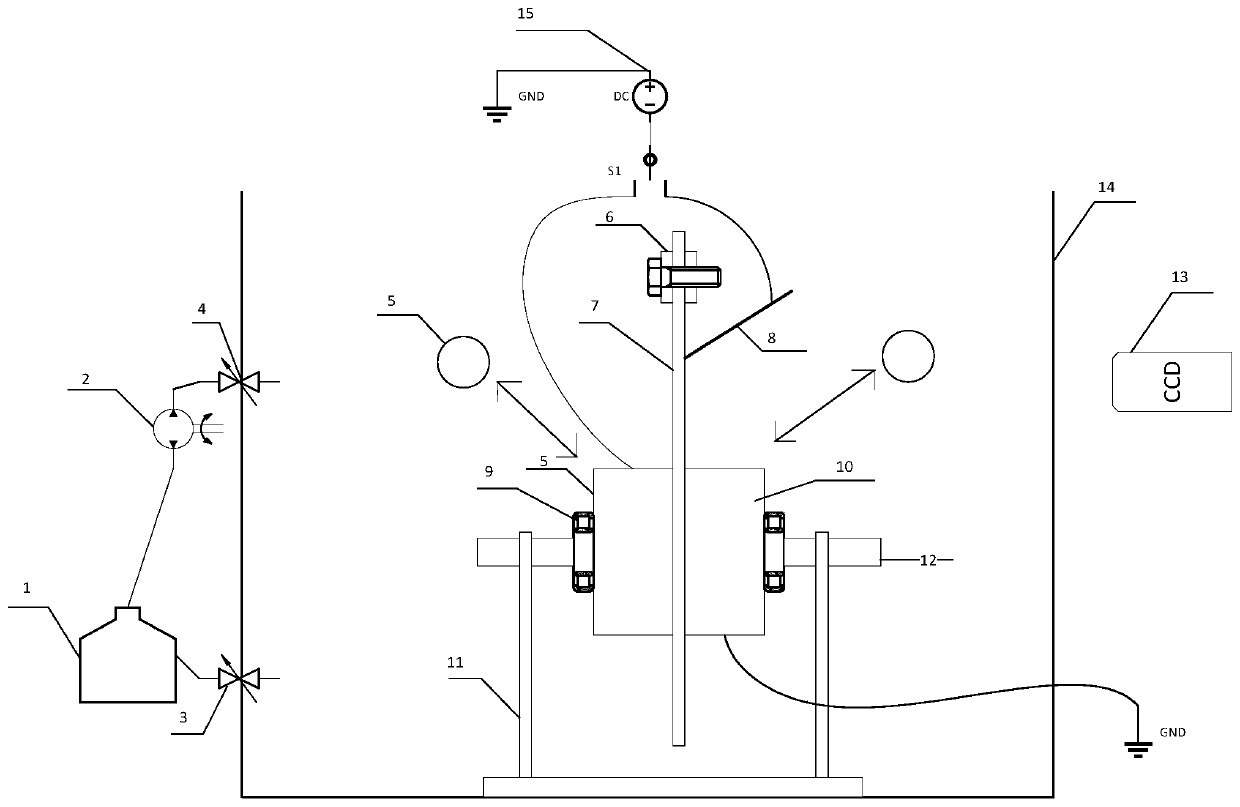

[0019] like figure 1 As shown, this embodiment includes: an oil bath module, a high-voltage source module, a CCD observation module, a detection electrode and an insulating support module, wherein: the detection electrode and the insulating support module are arranged inside the oil bath module to flashover the sample along the surface The CCD observation module for real-time observation of breakdown and breakdown is located outside the oil bath module. The high-voltage source module is connected to the detection electrode and switches between the high voltage of the flashover test along the surface and the high voltage of the breakdown test through a high-voltage relay.

[0020] like figure 1 As shown, the heating oil tank 1, the flow motor 2, and the experimental oil tank 14 in the oil bath module provide temperature control for the entire measurement process, and at the same time ensure that the high-voltage breakdown electrode 5, the locking structure 9, the ground electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com