Integrated insole and processing technique thereof

An insole and fabric technology, which is applied in the field of integrated insole and its processing technology, can solve the problems of multiple labor and many sewing processes, and achieve the effects of saving costs, improving production efficiency, and reducing sewing and molding processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention is further described in detail.

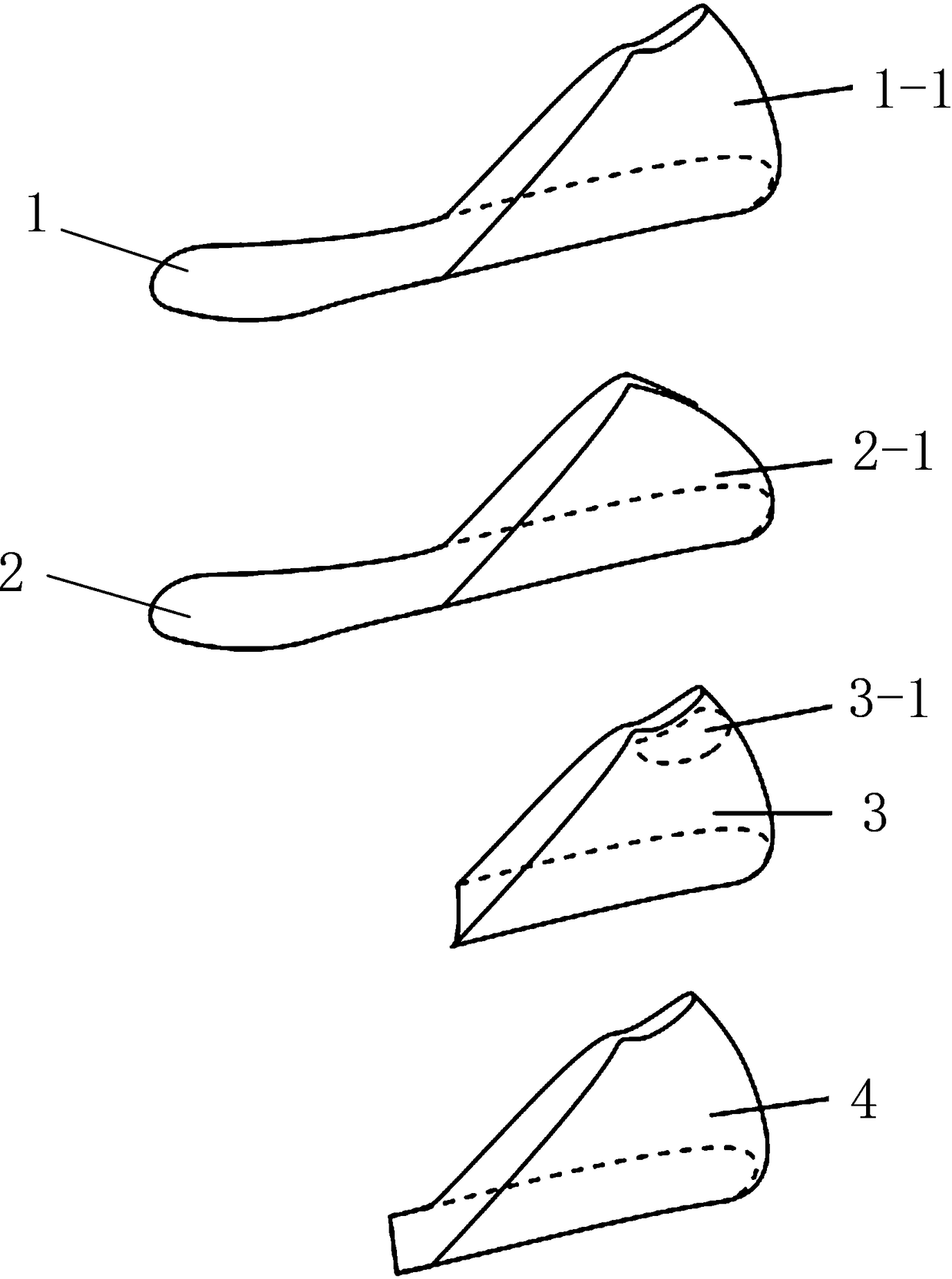

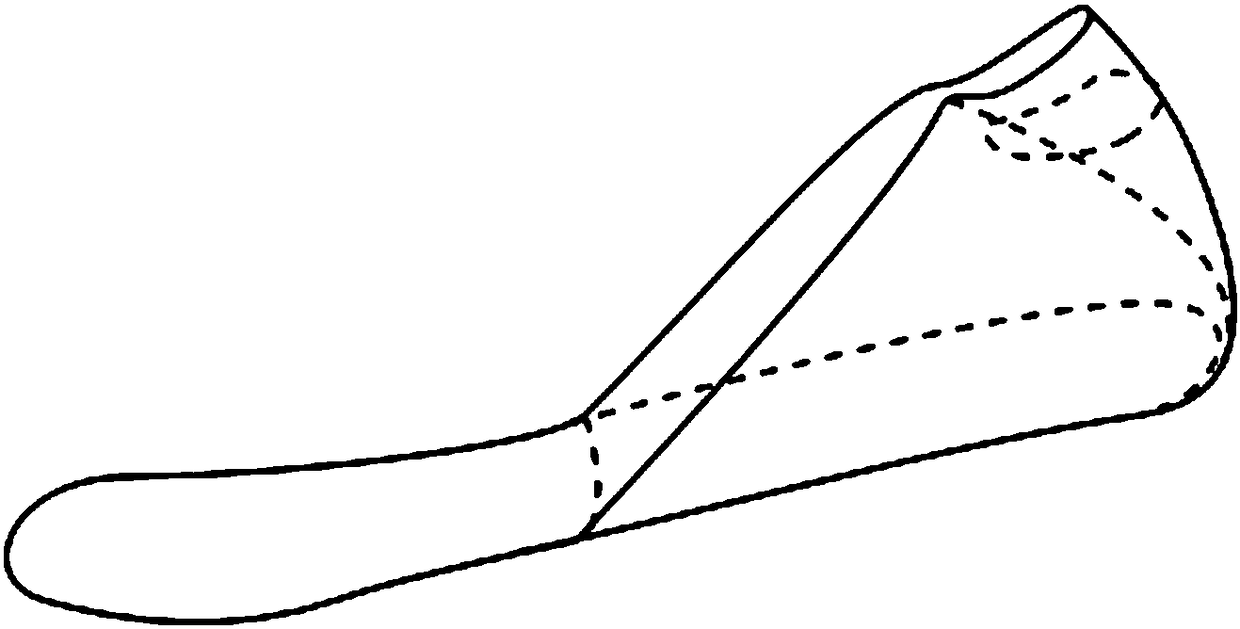

[0029] Such as figure 1 , figure 2 As shown, an integrated insole is characterized in that it includes an inner layer 1, a cloth layer 2, a rear heel shaping layer 3 and an exposed layer 4, and the inner layer 1 and the cloth layer 2 are respectively provided with a rear heel guard 1- 1 and the rear heel protection part 2-1, the cloth layer 2 covers the outer surface of the inner inner layer 1, the rear heel shaping layer 3 covers the outer surface of the rear heel protection part 2-1 of the cloth layer 2, and the exposed layer 4 covering the outer surface of the rear heel shaping layer 3 .

[0030] The inner layer 1 is made of high elastic cloth composite sponge.

[0031] The cloth layer 2 is a cloth with a very small elasticity, which is used to control the length of the bottom, and will not be deformed due to the large elasticity when the overshoe last is formed. The bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com