The method of clamping the bottle blowing mold by using the clamp during turning

A mold and turning technology, which is applied in the field of clamping the bottle blowing mold by using fixtures during turning, can solve the problems of extrusion dents on the surface of the mold core and the inability to guarantee the accuracy of coaxiality, etc., to improve the coaxiality of the inner and outer circles , to ensure the effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

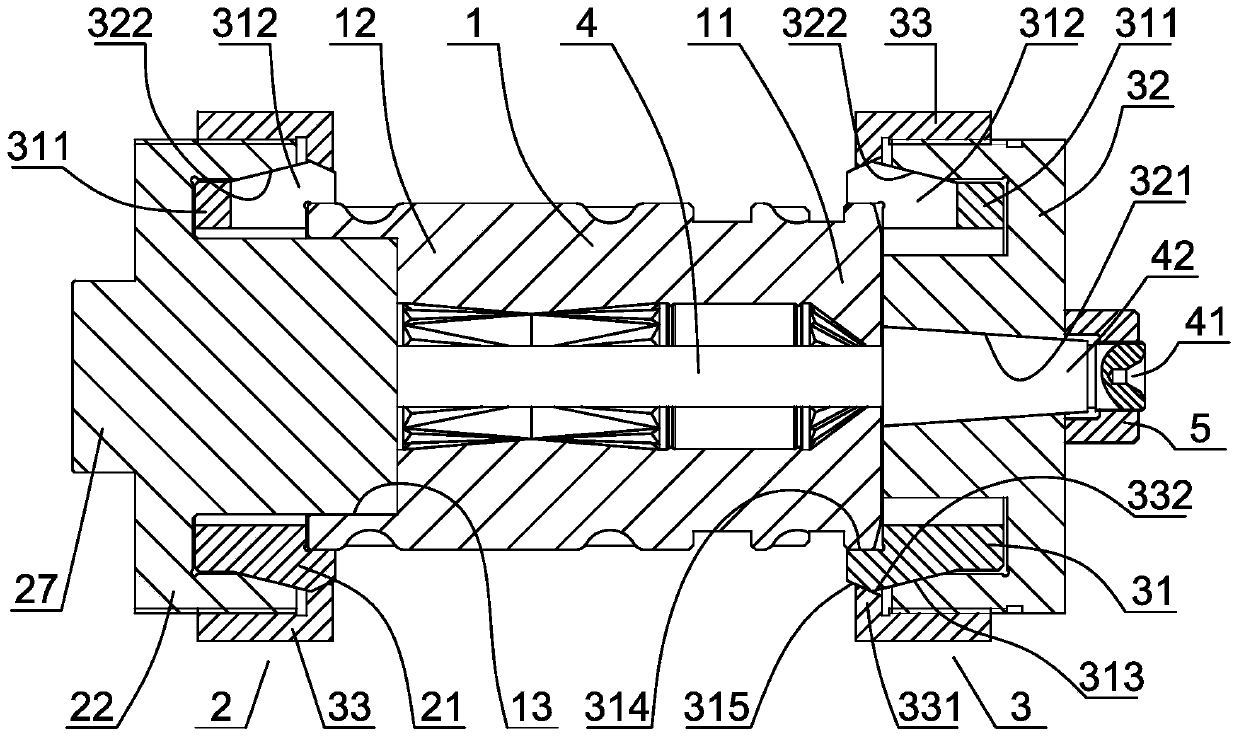

[0040] like figure 1 Shown, a kind of method that utilizes fixture to carry out clamping to bottle blowing mold when turning, described bottle blowing mold comprises splicing into cylindrical Hafur type mold core 1, is provided with mold cavity in the Hafur type mold core, The right end of the Hafur mold core is the bottle mouth end 11 corresponding to the cavity and the bottle mouth, and the left end is the bottle bottom end 12 corresponding to the cavity and the bottle bottom. Groove 13, so that setting is used for the mosaic block at the bottom of the beverage bottle bottle, specifically comprises the following steps:

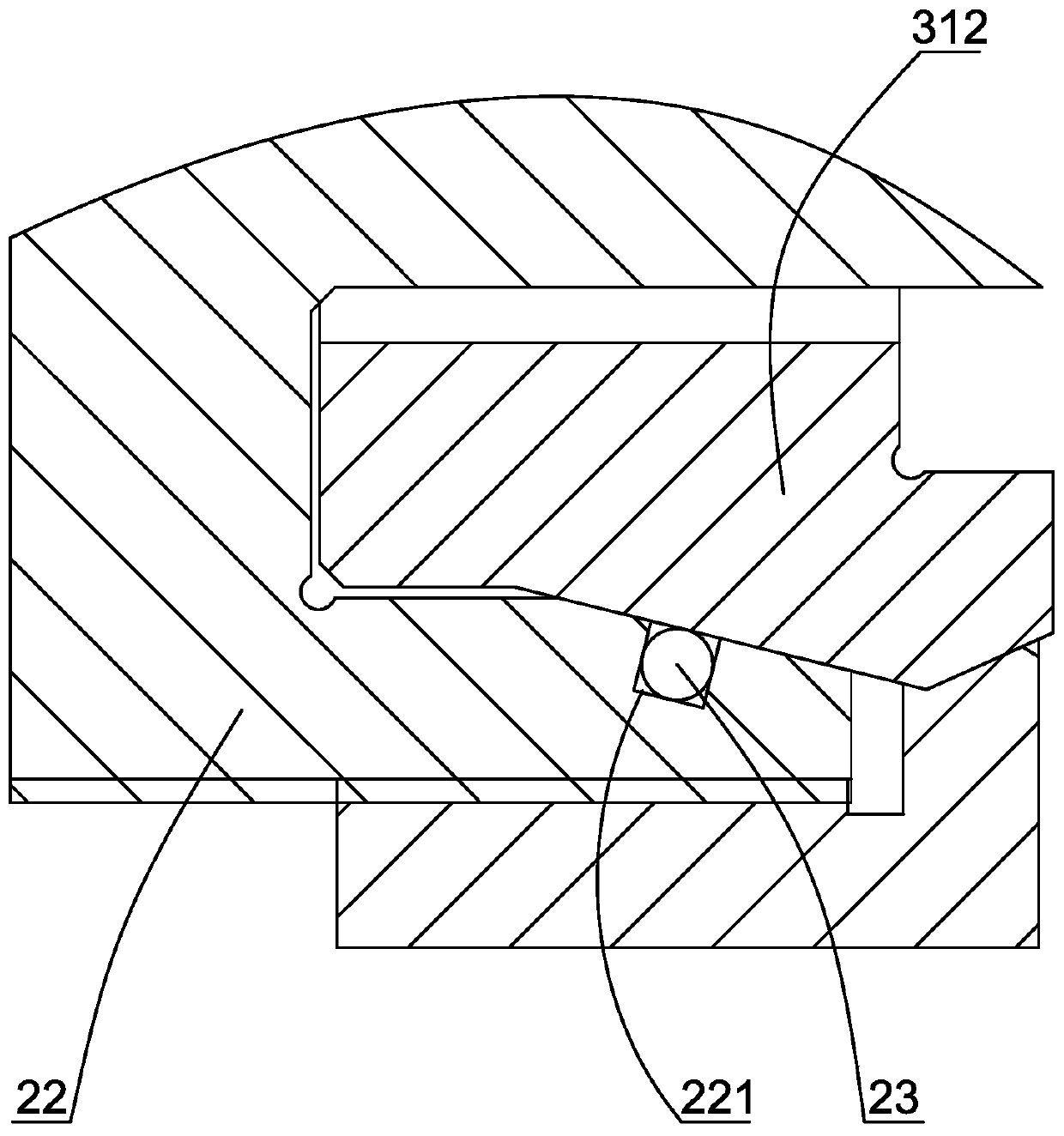

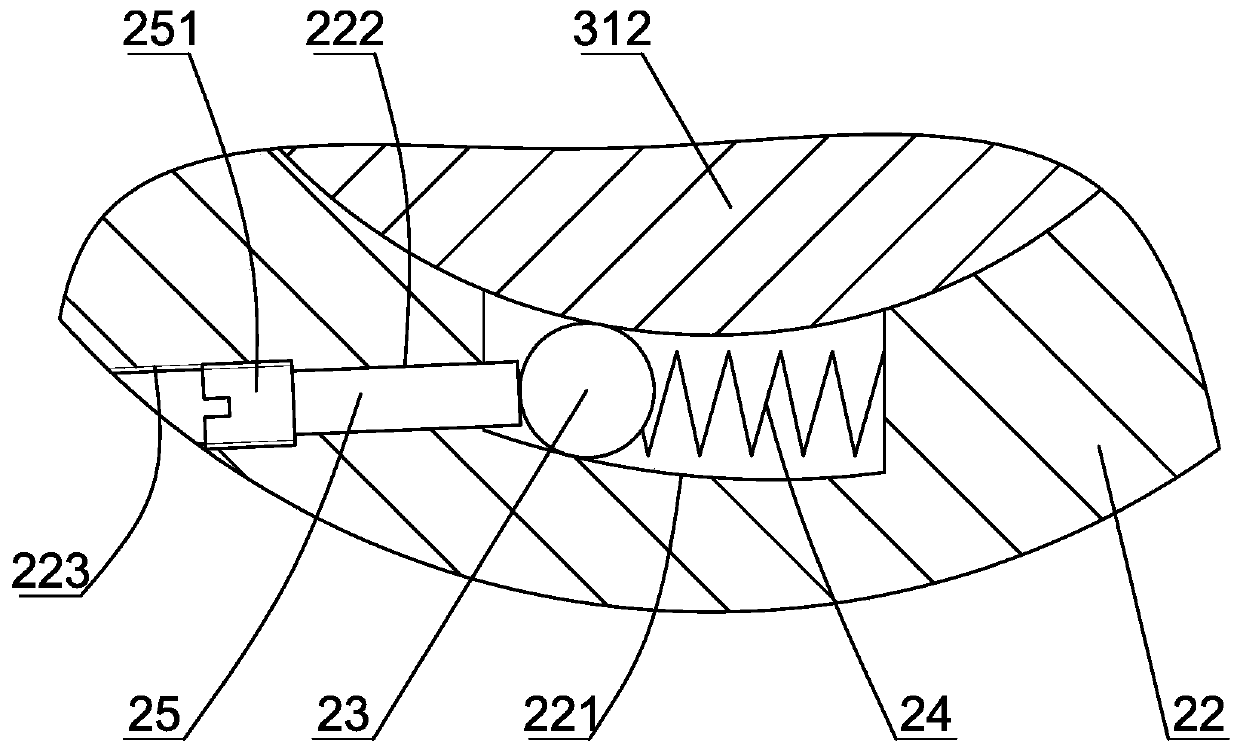

[0041] a. Use a left clamping device 2 with a first elastic positioning element 21 to clamp the bottle bottom end of the Hafur type mold core, and the first elastic positioning element is closely attached to the circumferent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com