A drillable fracturing bridge plug

A kind of fracturing and bridge plug technology, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc. It can solve long-term problems ranging from 2-3 hours to more than ten hours. Drilling bridge plugs are not involved in the field of fracturing, and no problems such as low casing damage have been found, so as to reduce the workload, save the anti-retraction mechanism and shorten the operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention is described in further detail:

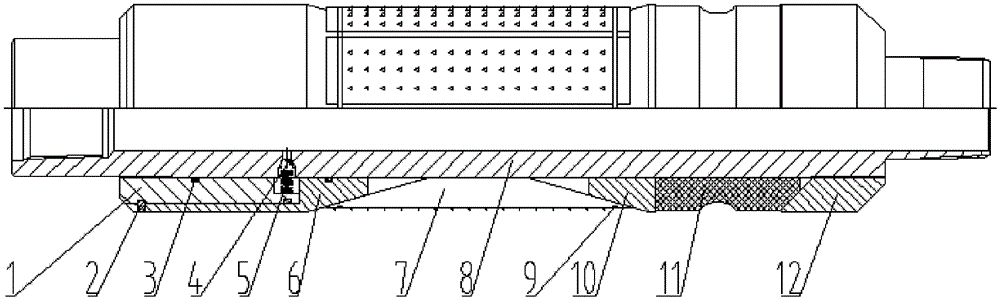

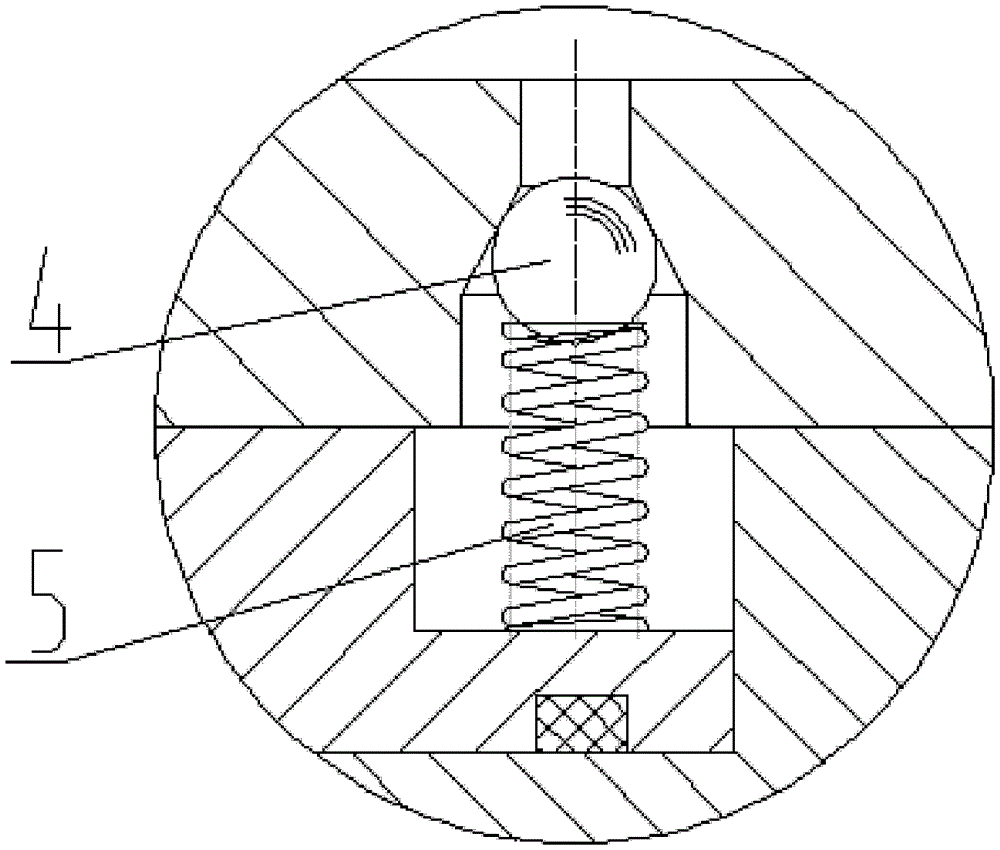

[0035] Such as figure 1As shown, a drillable fracturing bridge plug includes a central tube 8 and a retaining ring 1, a piston 6, slips 7, and a lower vertebral body 10 that are sequentially sleeved on the central tube 8 and coaxial with the central tube 8. , rubber cartridge 11, protective bowl 12;

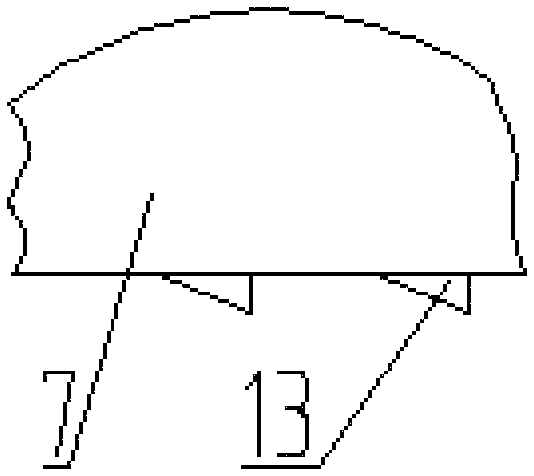

[0036] The slip 7 is an integral slip, which is a sleeve structure, and its outer surface is a cylindrical surface, and oblique triangle anchor teeth 13 are evenly distributed on the outer surface, such as image 3 As shown, the inclination direction of all oblique triangular anchor teeth 13 is towards the same direction; its central hole sequentially includes an upper tapered hole, a cylindrical hole and a lower tapered hole; the hole wall of the cylindrical hole and the central tube 8 contact with the outer surface; the minimum diameters of the upper tapered hole an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com