EVA secondary foaming formation method

A technology of secondary foaming and molding method, applied in the field of EVA secondary foaming molding, can solve the problems of low production efficiency, high labor intensity, poor working environment, etc., to improve production efficiency, reduce labor intensity, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

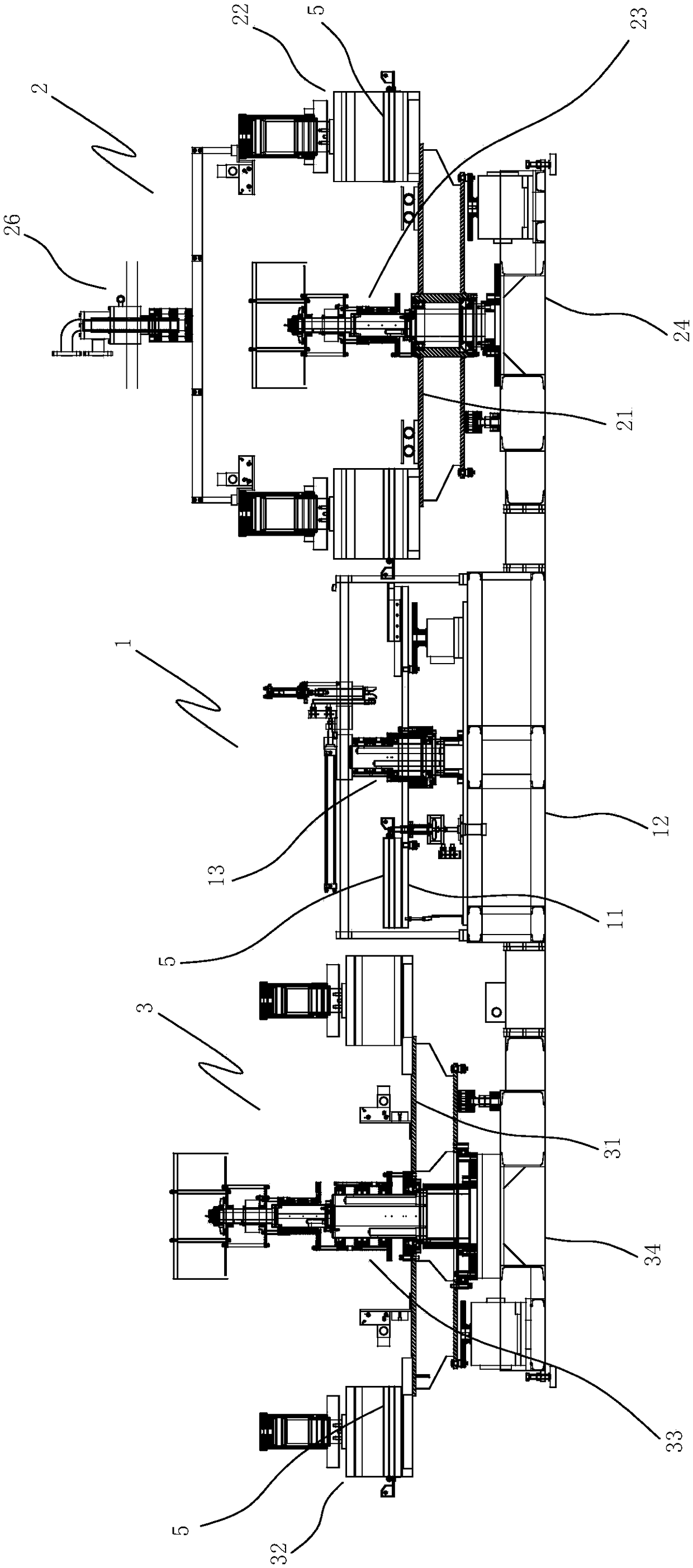

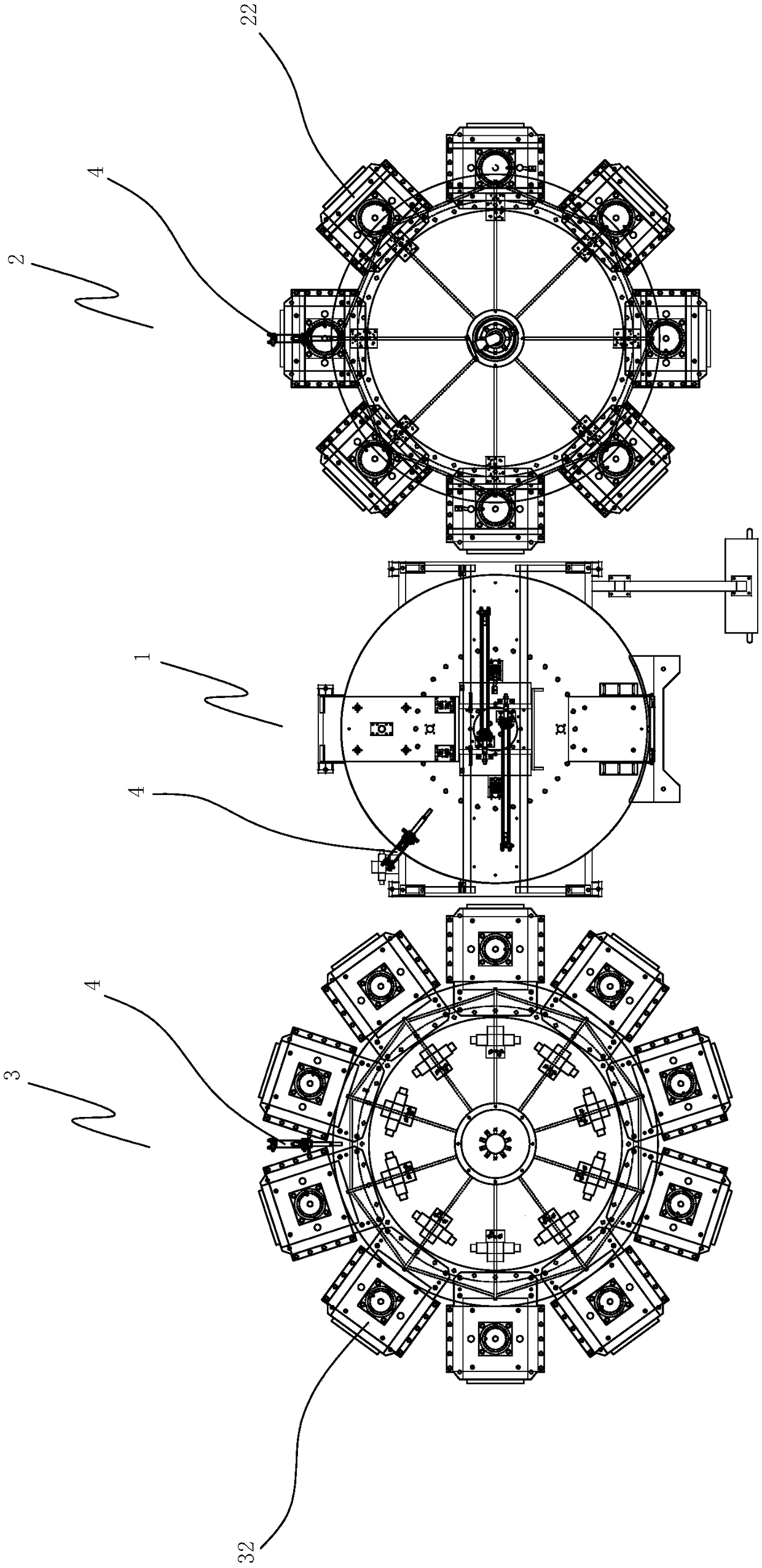

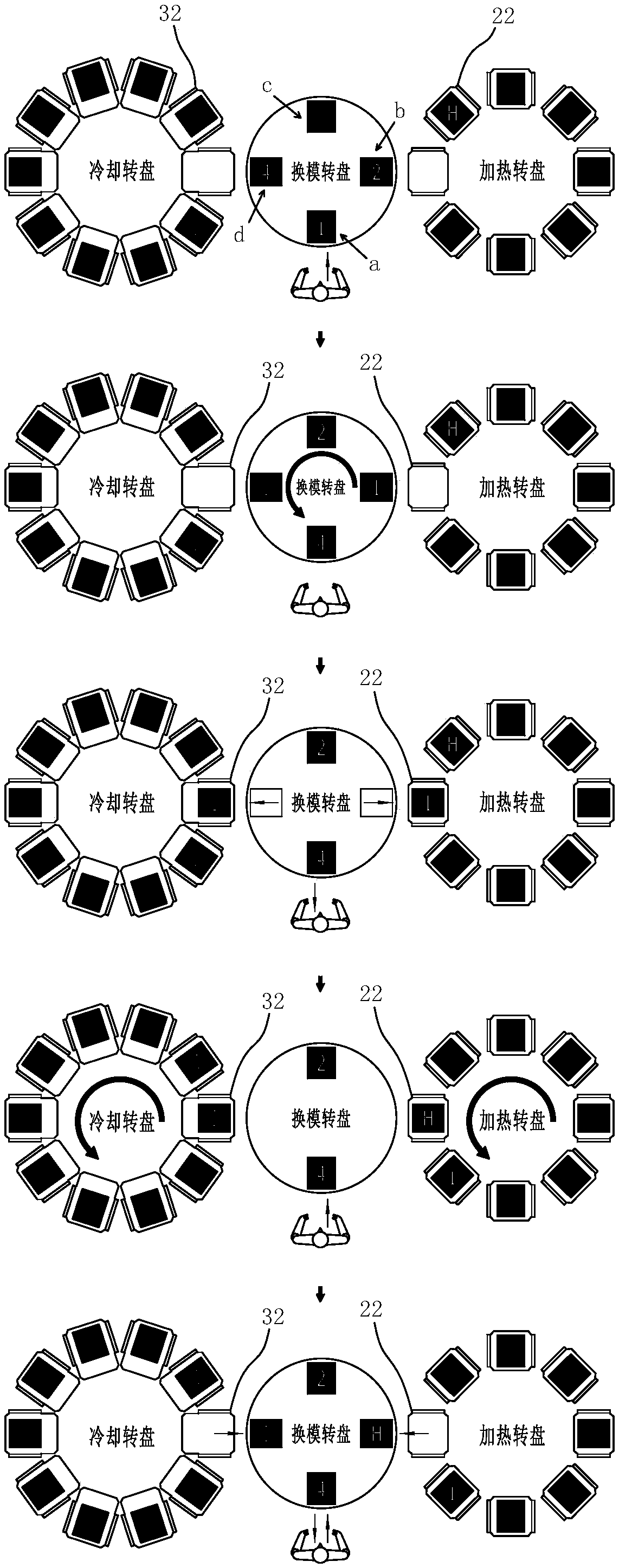

[0042] refer to Figure 1 to Figure 11 As shown, an EVA secondary foam molding system includes a mold changing device 1 , a heating device 2 and a cooling device 3 .

[0043] The heating device 2 has a heating turntable 21 which can rotate intermittently. The heating turntable 21 is provided with a plurality of heating stations 22 distributed in a circle. The cooling device 3 has a cooling turntable 31 which can rotate intermittently. A plurality of cooling stations 32, the mold changing device 1 has a mold changing turntable 11 that can rotate intermittently, a heating manipulator for pushing the mold 5 on the mold changing turntable 11 into the heating station 22 or pulling it back from the heating station 22, and a heating manipulator for The mold 5 on the mold changing carousel 11 is pushed into the cooling station 32 or the cooling manipulator that is pulled back from the cooling station 32 .

[0044] Specific reference figure 1 , figure 2 , Figure 6 and Figure 7A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com