Charging pile facilitating cleaning and dust removal of air inlet

A charging pile and air inlet technology is applied in the field of charging piles that are convenient for cleaning and dust removal at the air inlet, and can solve the problems of inconvenient cleaning of dustproof nets and vents, reduced charging reliability, inconvenient opening and closing of dustproof nets, and the like, and achieves a simple structure. , The effect of convenient later maintenance, convenient and quick opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

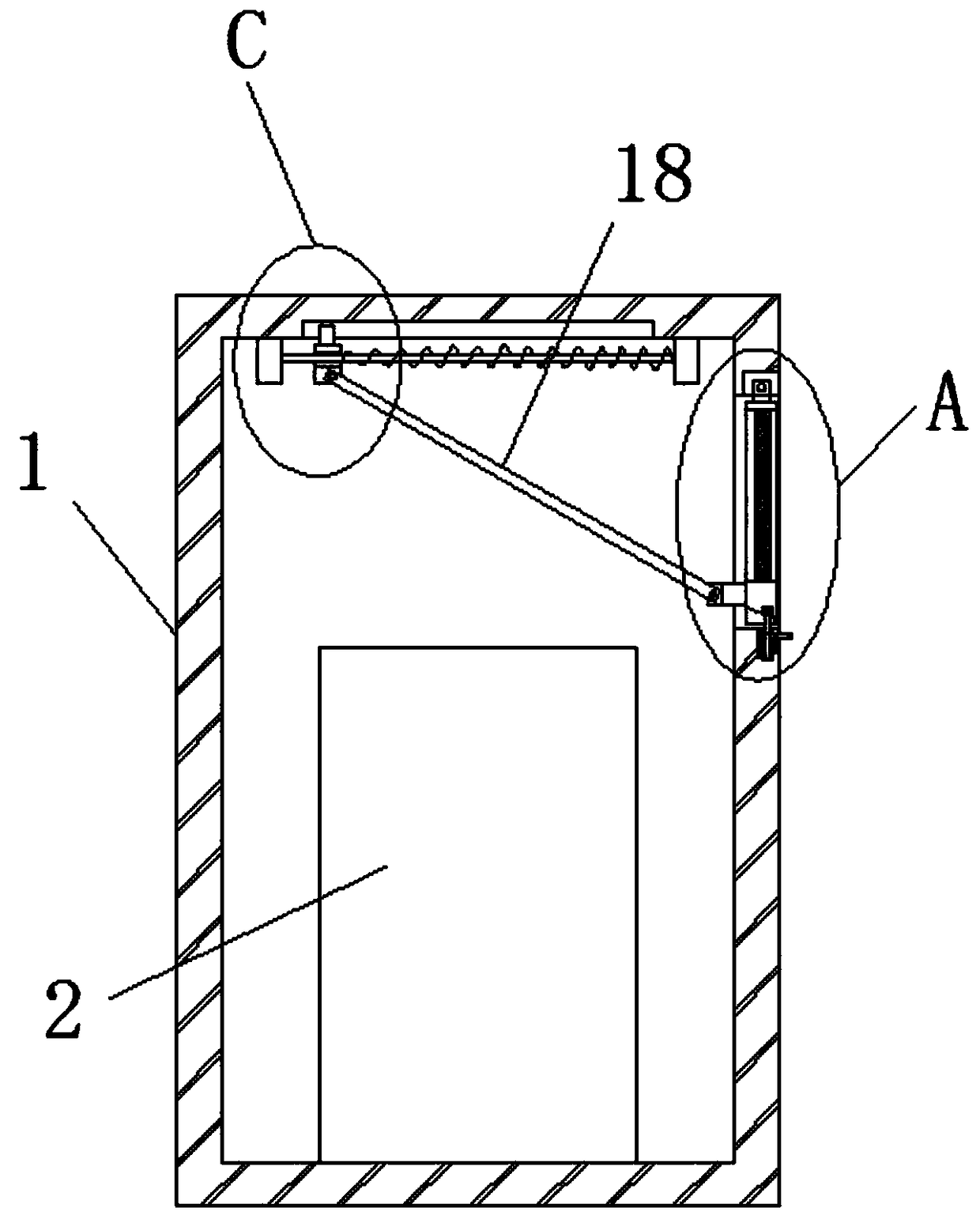

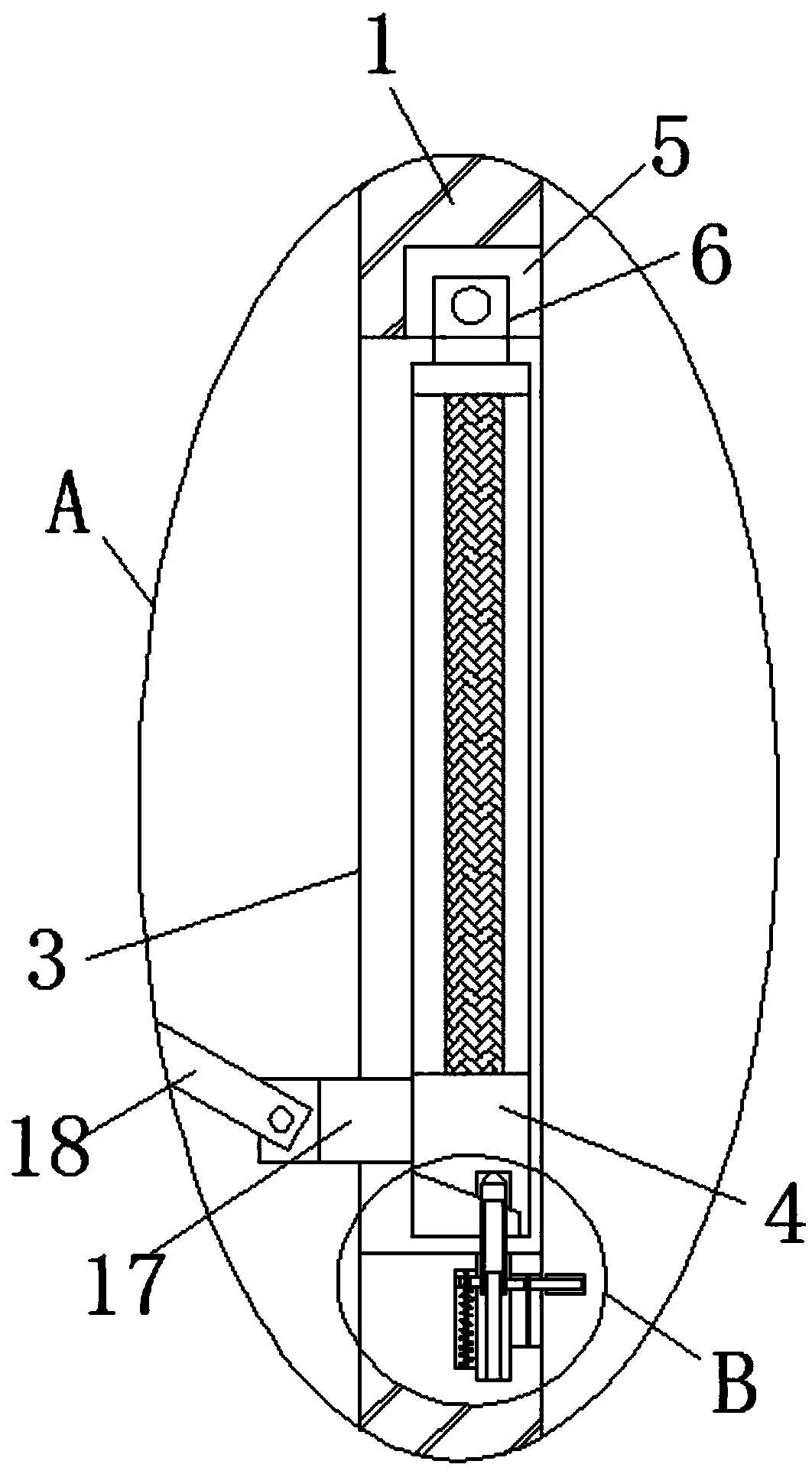

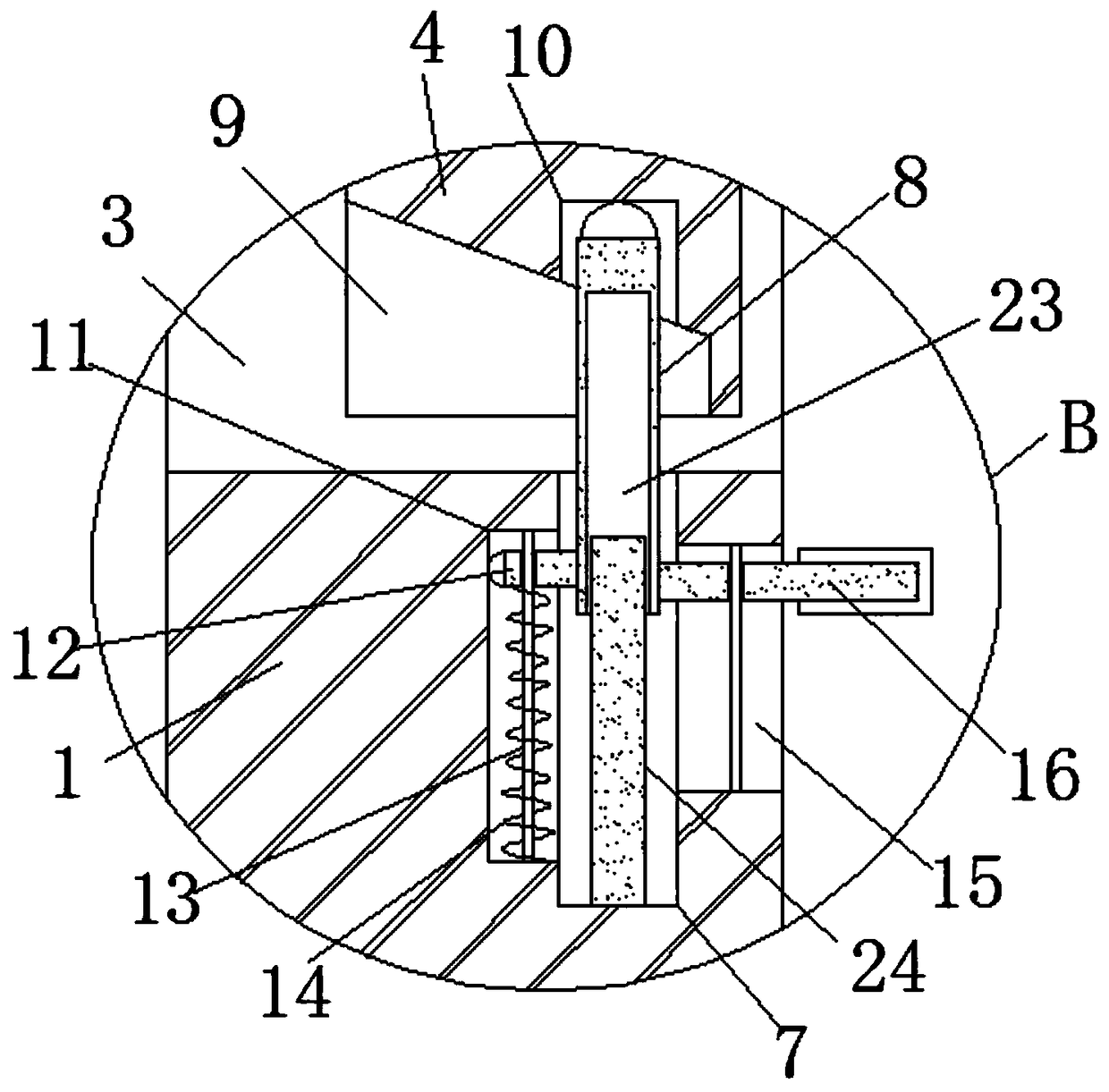

[0022] refer to Figure 1-5 In this embodiment, a charging pile that facilitates the cleaning and dust removal of the air inlet is proposed, including a housing 1, a charging pile body 2 is fixedly installed on the inner wall of the bottom of the housing 1, and a first through hole 3 is opened on one side of the housing 1. The first through hole 3 is provided with a dustproof plate 4, the top inner wall of the first through hole 3 is provided with a mounting groove 5 with one side open, the top of the dustproof plate 4 is fixedly installed with a connecting seat 6, and the top of the connecting seat 6 Rotationally installed in the installation groove 5, a first groove 7 is opened on the bottom inner wall of the first through hole 3, and a fixed rod 8 is slidably installed in the first groove 7, and the top end of the fixed rod 8 extends to the first through hole 3 Inside, the bottom of the dustproof plate 4 is provided with a wedge-shaped groove 9 with an opening on one side, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com