Electromagnetic separated brake assist device for automobile

A booster device and automobile technology, applied in the direction of brake transmission, vehicle parts, transportation and packaging, etc., can solve the problems of brake performance degradation, high cost of use, small torque, etc., to achieve fast start-up speed, long service life, The effect of increasing torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described:

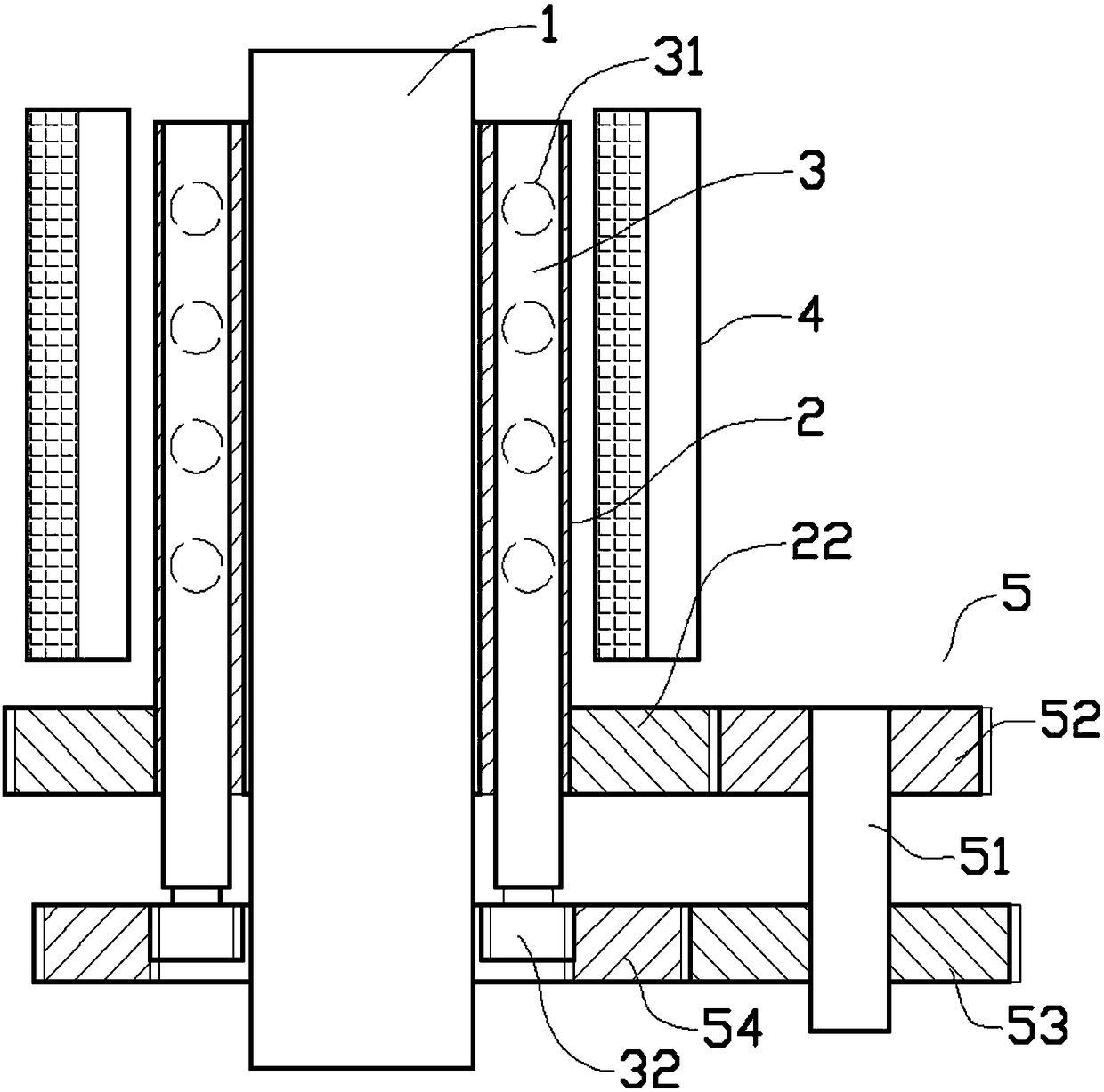

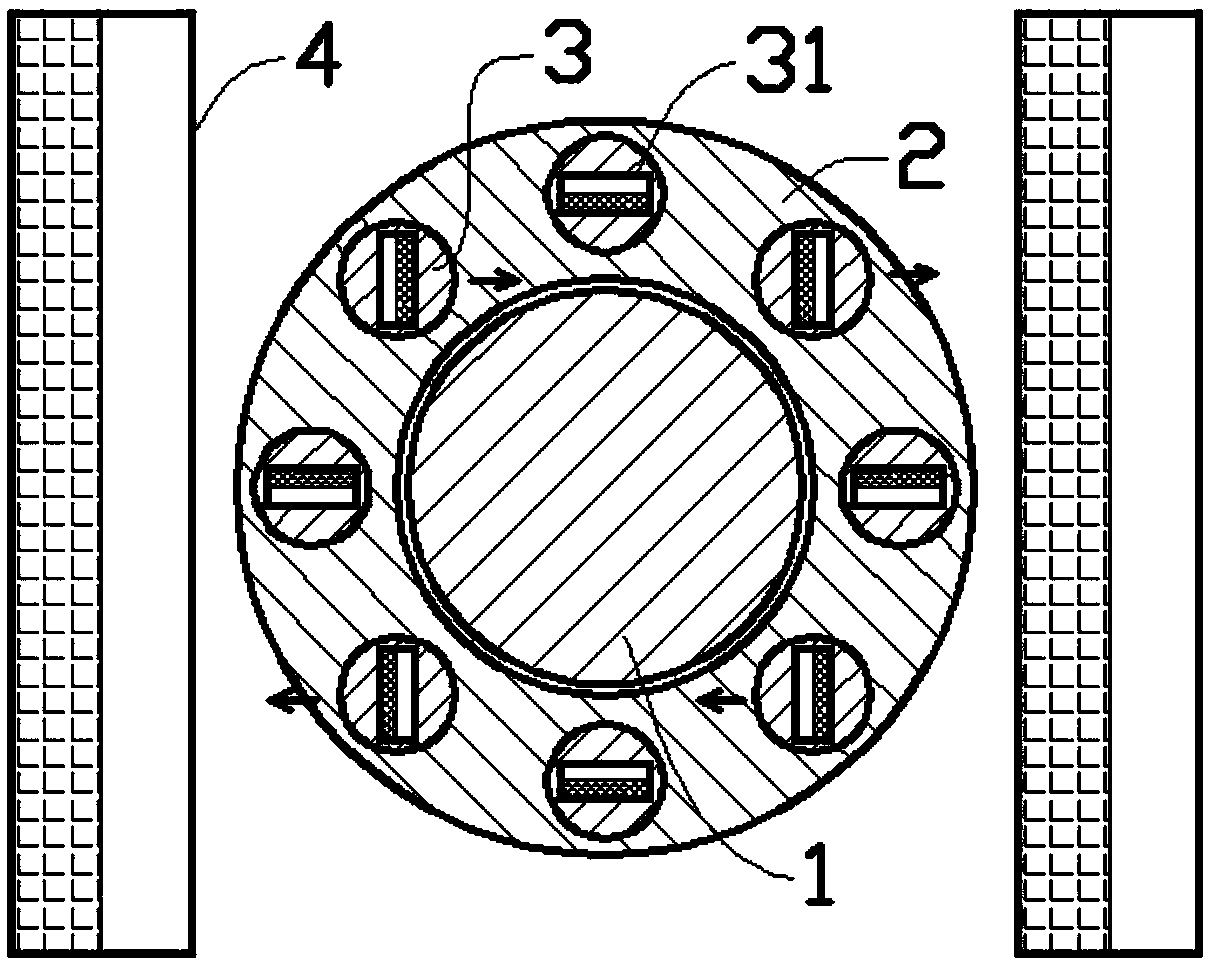

[0014] like figure 1 and figure 2 As shown in the embodiment, the automobile electromagnetic air brake booster device includes a resistance ring 2 assembled on the outside of the transmission shaft 1 of the automobile, the resistance ring 2 is assembled horizontally and coaxially with the transmission shaft 1, and the resistance The ring 2 is processed with mounting holes evenly distributed and horizontally surrounding the axis of the resistance ring 2. A transmission rod 3 that can rotate from the axis is installed in the installation hole. In the transmission rod 3, inner magnetic blocks 31 are uniformly distributed along the axis. The north-south magnetic pole connection line of the inner magnetic block 31 is perpendicular to the axis of the resistance ring 2; the left and right sides of the resistance ring 2 are respectively equipped with electromagnetic plates 4, and one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com