Gear choosing and gear shifting device for vehicle

A technology for shifting gears and motor vehicles, which is applied to control devices, vehicle components, transportation and packaging, etc., can solve problems such as increasing the rotation angle of gears, poor load characteristics during gear shifting, and unfavorable working life of mechanisms, etc., to achieve aggravated wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

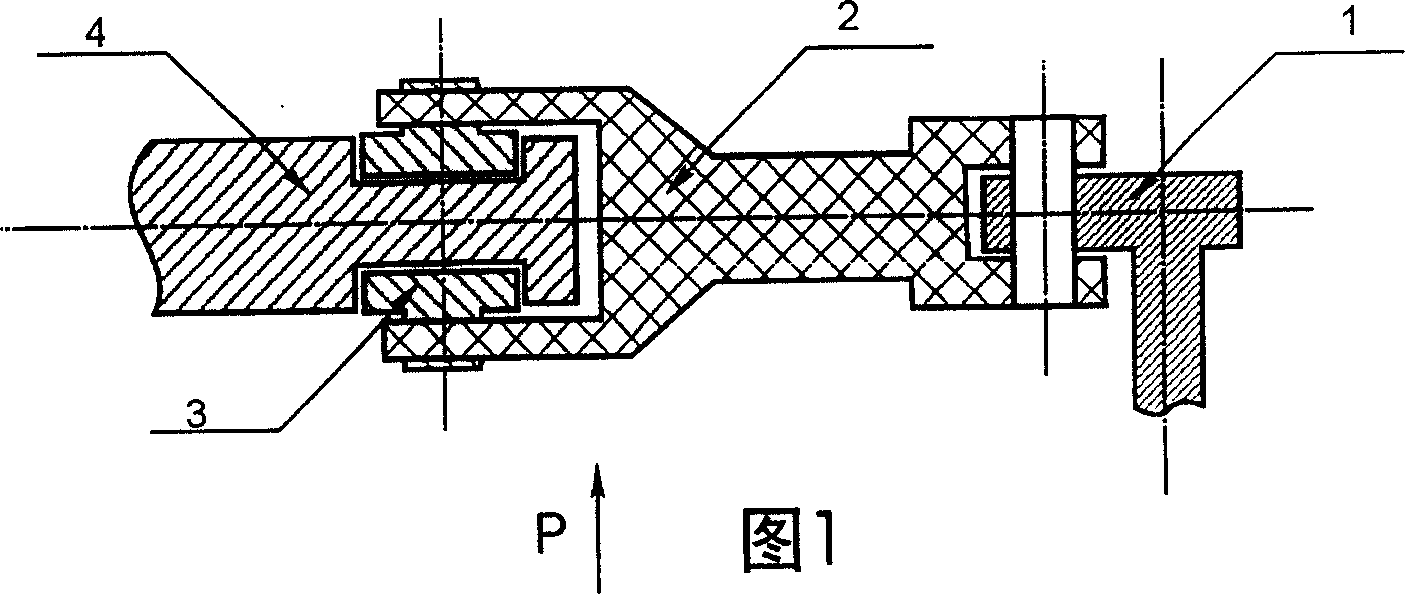

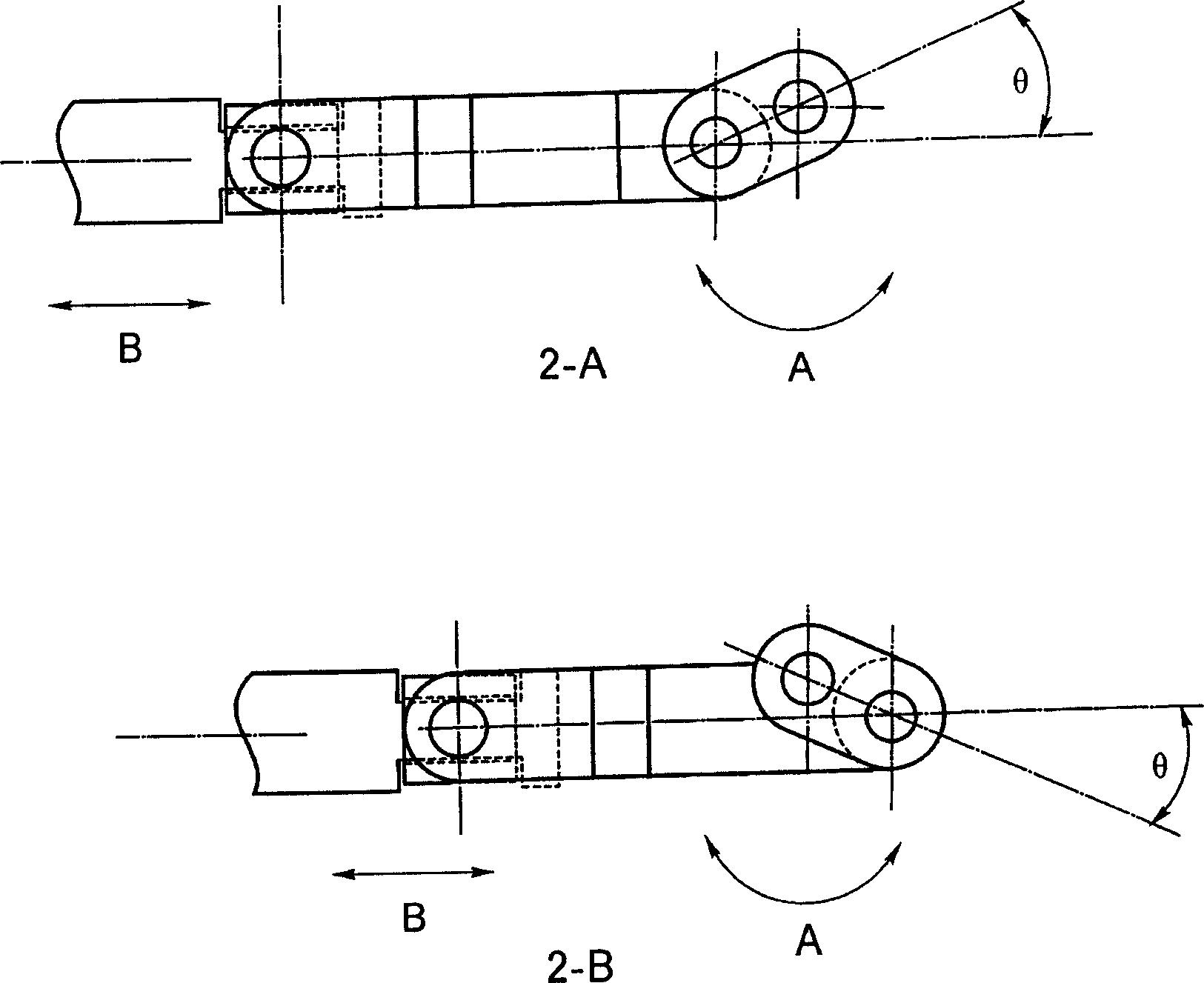

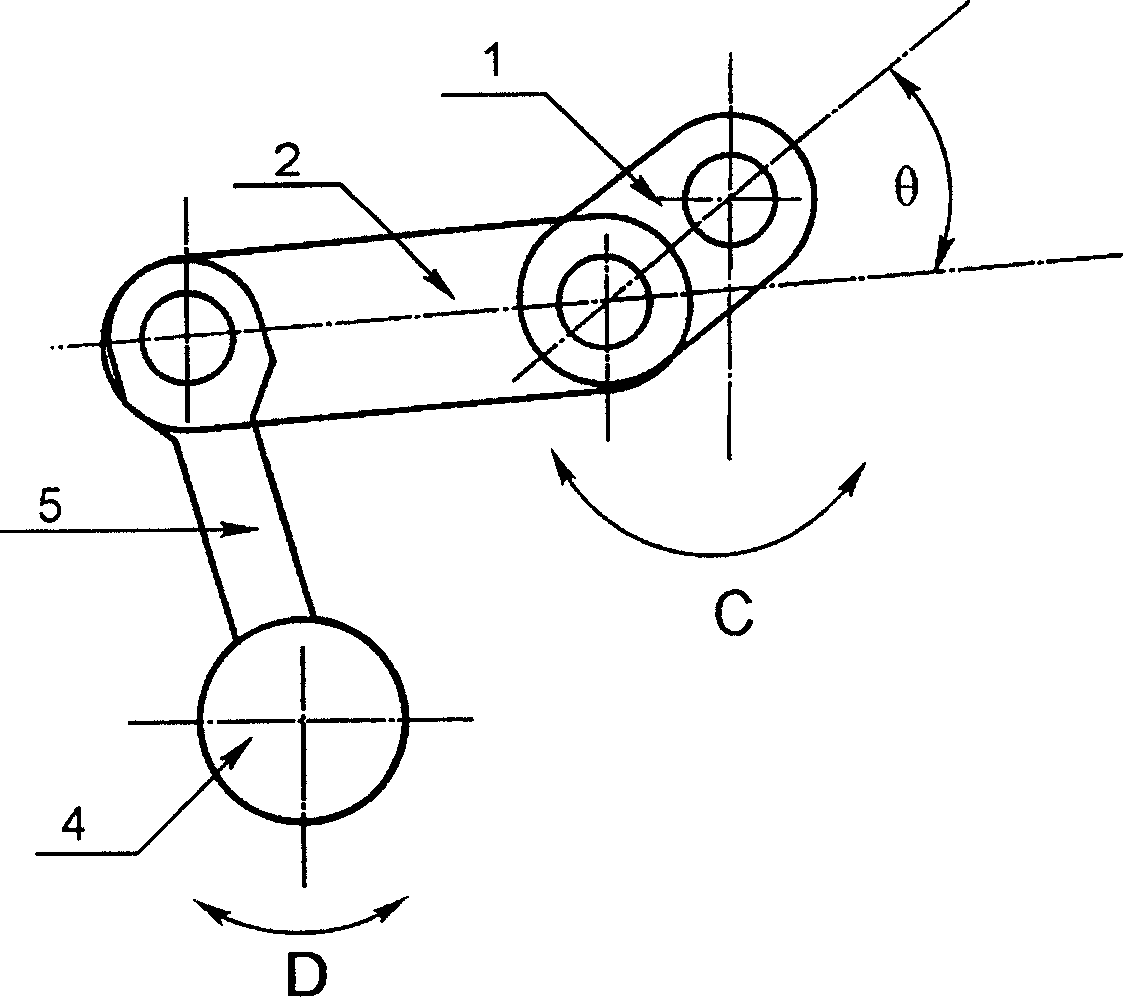

[0023] Figure 1 and figure 2 Shown, is a kind of structural form of the gear shifting device of the present invention. The selector shift lever 4, which can move back and forth along its length axis and / or swing around the length axis, is hinged to one end of the connecting rod 2 with a fork pin end structure through the hinge sleeve 3 at the end of its length direction, The other fork pin structural end of the connecting rod 2 is hinged to the swing end of the eccentric arm 1 which can swing back and forth under the drive of the driving mechanism. The swing range of the eccentric arm 1 should be that when it is at the limit position of swinging on both sides, the acute angle θ between its radial direction (that is, the length of the eccentric arm) and the reciprocating direction of the connecting rod 2 is ≤30°. The gear selection lever 4 is connected to the connecting rod through the composite hinge sleeve 3 hinged to each other in an orthogonal manner, so that mechanical in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com