An Effective Loss Reduction Type Closed Fan

A technology for closing fans and reducing losses, applied in conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of reducing the practicability of closing fans, leakage of air at the connection, poor sealing effect, etc. Guaranteed air-tight performance and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

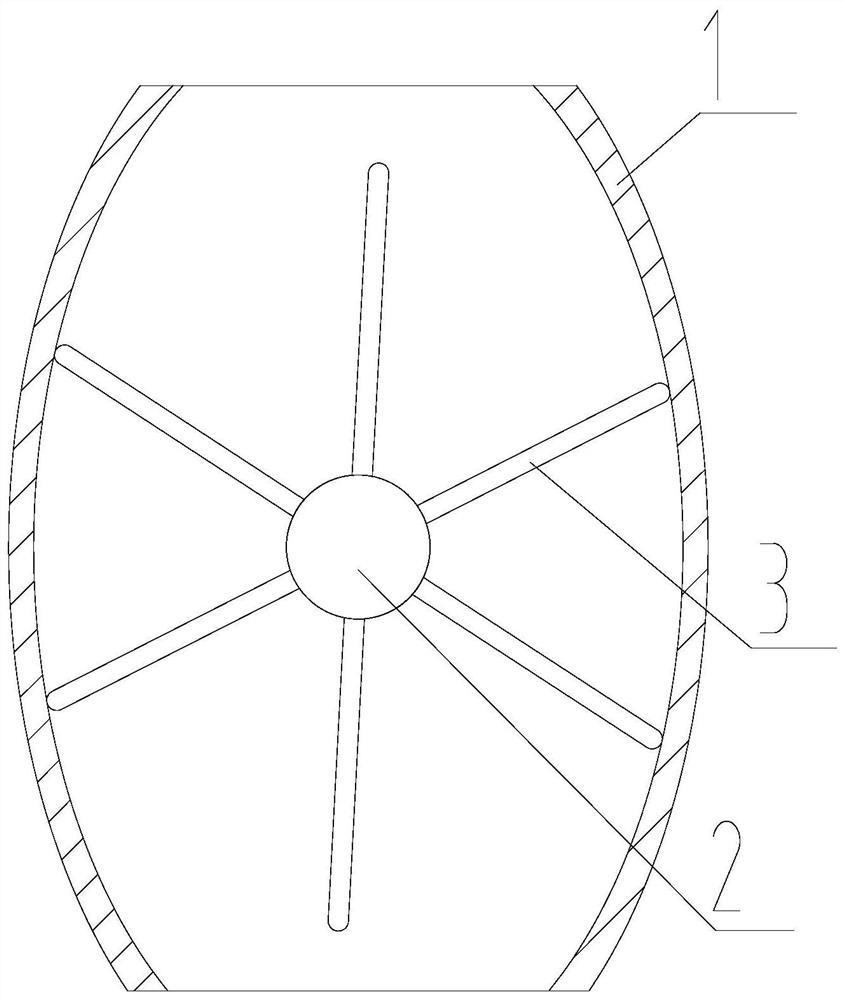

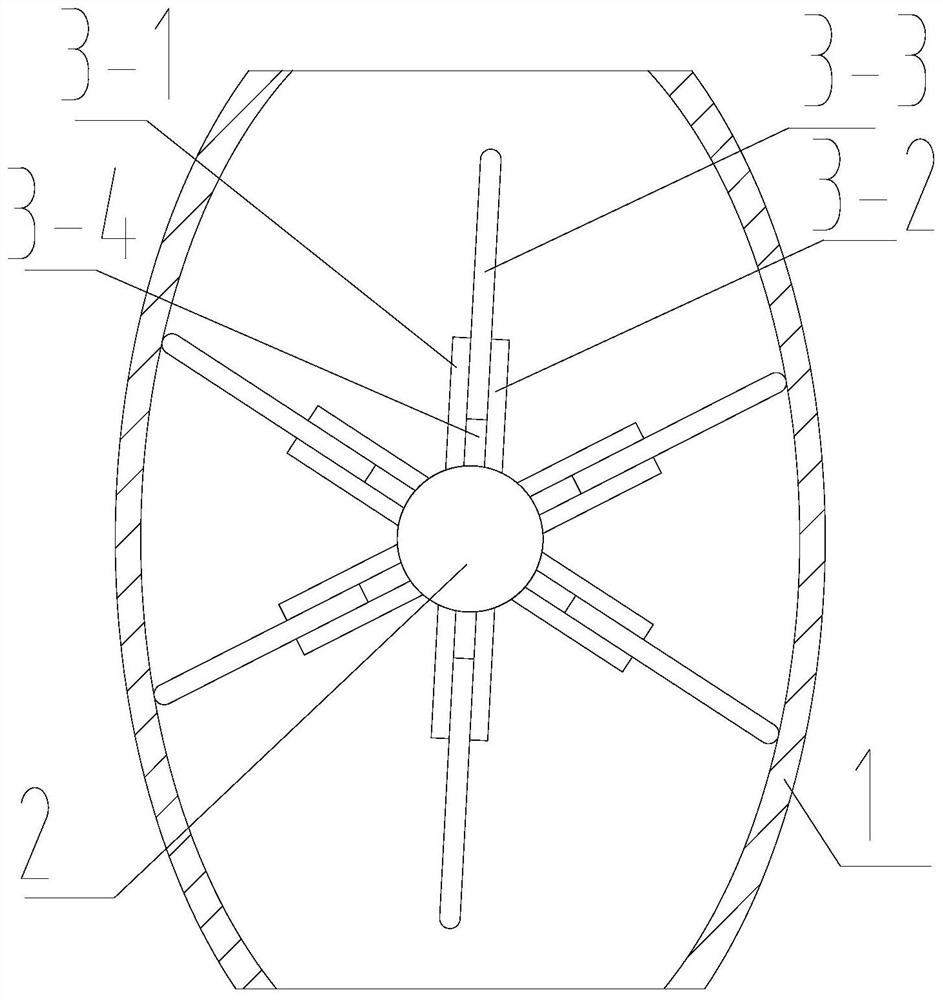

[0022] In this embodiment, the fan blade 3 includes a first splint 3-1, a second splint 3-2, a scraper 3-3 and an elastic sealing strip 3-4, and the first splint 3-1 and the second splint 3-2 are connected to each other. Installed parallel to the shaft 2, the width of the gap between the first splint 3-1 and the second splint 3-2 is equal to the thickness of the scraper 3-3, and the elastic sealing strip 3-4 is bonded to the shaft 2 and is located on the second splint. Between the first splint 3-1 and the second splint 3-2, the scraper 3-3 is inserted into the gap between the first splint 3-1 and the second splint 3-2 and bonded to the elastic sealing strip 3-4. The scraper 3-3 extends along the radial direction of the rotating shaft 2 in the width direction. In this way, during the rotation of the rotating shaft 2, the scraper 3-3 expands and contracts with the change of the inner diameter of the side of the housing 1, ensuring that the fan blade 3 divides the space inside th...

Embodiment 2

[0025] In the embodiment, the fan blade 3 is composed of a blade and a film, the blade is installed on the rotating shaft 2 , and the film is installed on the side of the blade away from the rotating shaft 2 . The soft sheet has a rubber construction. In this way, the gap between the blade and the housing 1 can be sealed by the film, ensuring the air-closing performance, avoiding the blade from scratching the inner wall of the housing, and reducing wear and tear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com