Rotary feeder shell body

A closed fan and casing technology, applied in the field of closed fan casing, can solve the problems of increasing the wear degree of fan blades and unfavorable service life of the closed fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

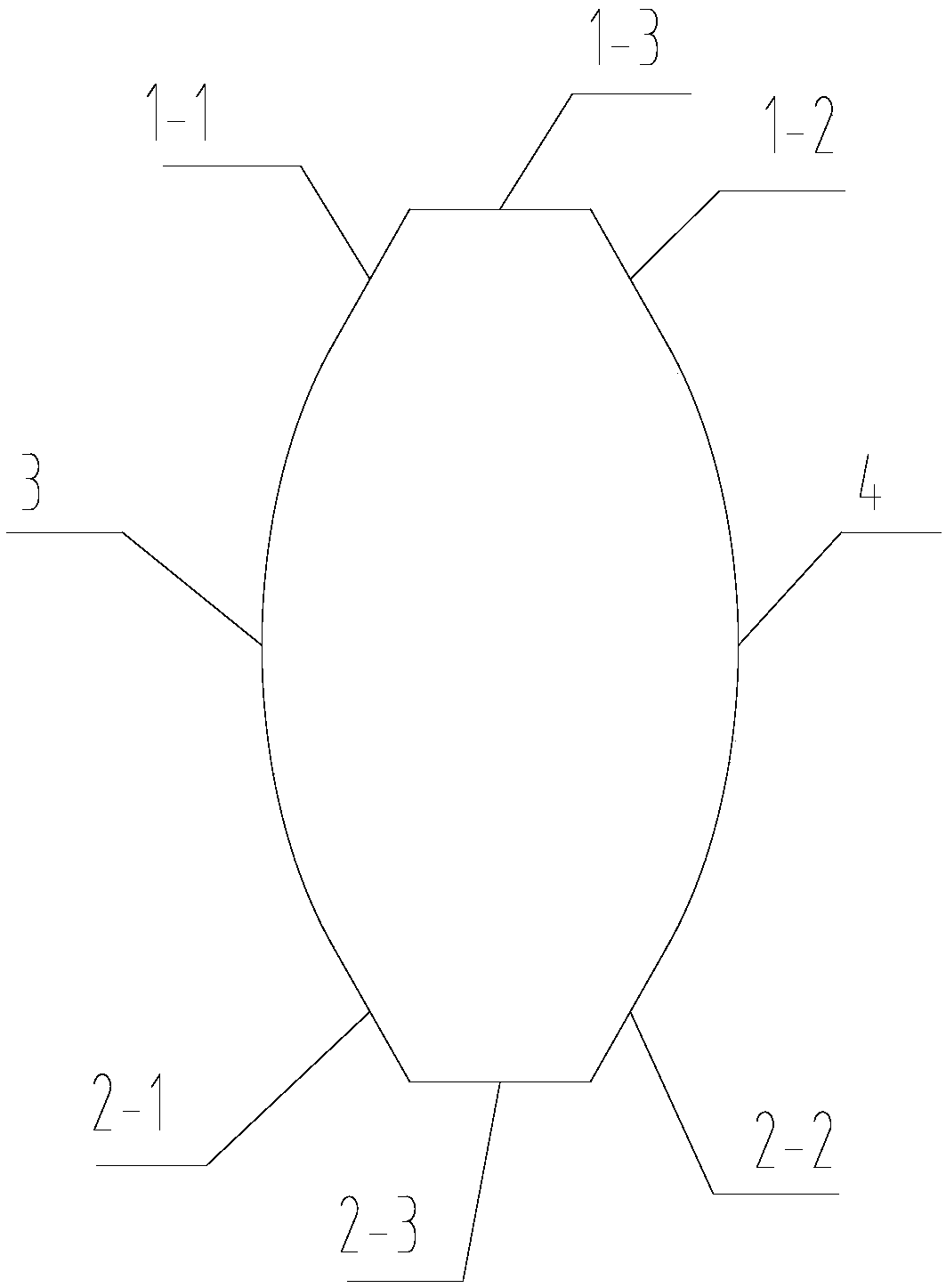

[0025] In this embodiment, the top surface 1 is composed of a first plane 1-1, a second plane 1-2 and a third plane 1-3, and the bottoms of the first plane 1-1 and the second plane 1-2 are respectively connected to the first The tops of the arc surface 3 and the second arc surface 4 are respectively tangent to the first arc surface 3 and the second arc surface 4, and the third plane 1-3 is arranged horizontally, and its two sides are respectively connected to the first plane 1-1 and the second arc surface. On the top of the second plane 1-2, the feed inlet is arranged on the third plane.

[0026] The bottom surface 2 is composed of the fourth plane 2-1, the fifth plane 2-2 and the sixth plane 2-3, and the tops of the fourth plane 2-1 and the fifth plane 2-2 respectively connect the first arc surface 3 and the second arc surface. The bottom of the arc surface 4 is tangent to the first arc surface 3 and the second arc surface 4 respectively, the sixth plane 2-3 is set horizontal...

Embodiment 2

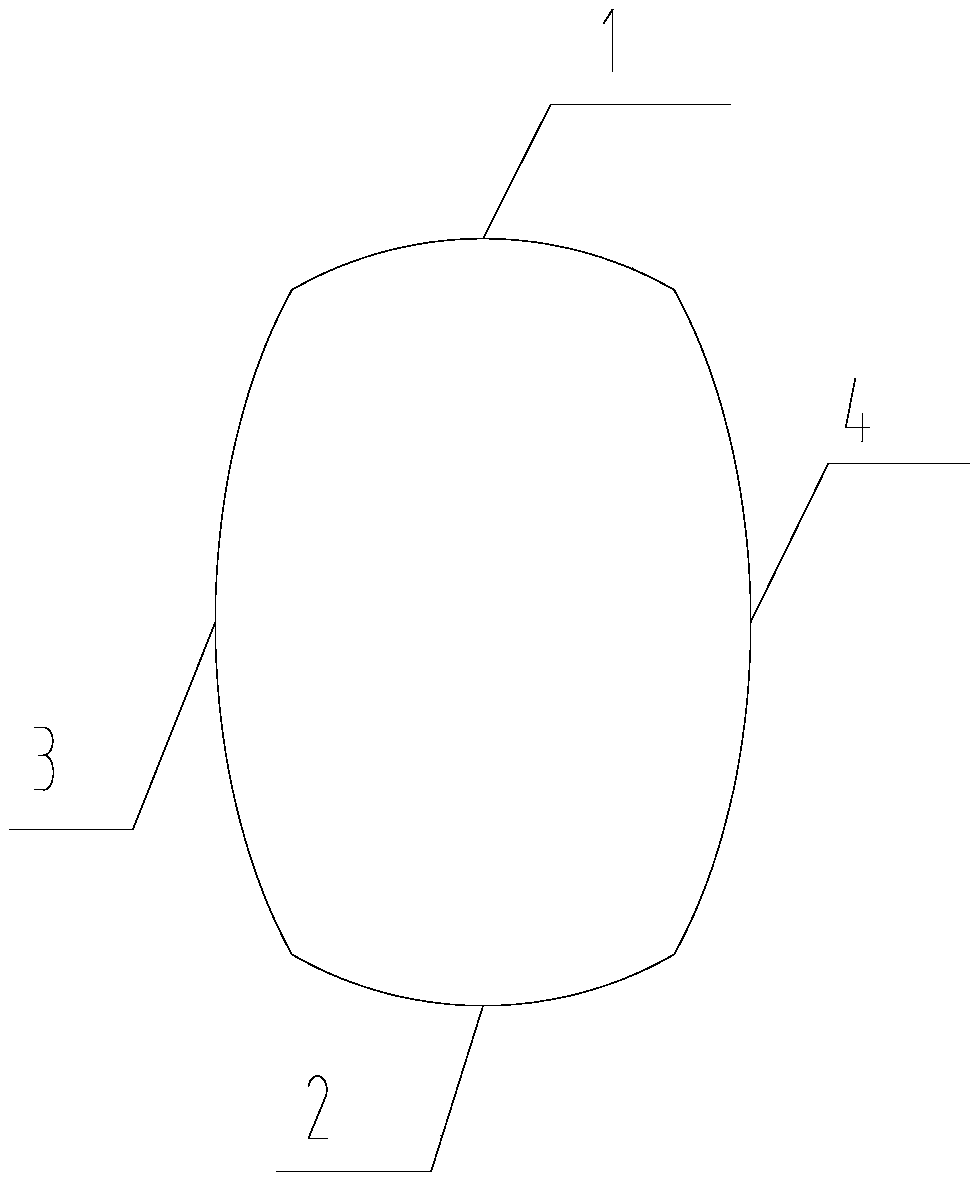

[0029] In this embodiment, the projection of the top surface 1 and / or the bottom surface 2 on the end surface is located on a circle B with a radius equal to L1, which is beneficial to reducing the volume of the entire housing.

Embodiment 3

[0031] In this embodiment, the projection of the top surface 1 and / or the bottom surface 2 on the end surface is located on the ellipse A. Further, the projections of the top surface 1 , the bottom surface 2 , the first arc surface 3 and the second arc surface 4 on the end surface form a complete ellipse A. In this way, the entire shell forms an elliptical cylindrical structure, which is convenient for processing and forming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com