A kind of method for separating chlorine gas from chlorine dioxide solution

A chlorine dioxide and solution technology, which is applied in the direction of chlorine dioxide and chlorine oxide, can solve the problems of persistent bioaccumulation, high toxicity, semi-volatility and long-distance migration, increased environmental threats, and large investment in equipment. Achieve good social and economic benefits, reduce production costs, and achieve high separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

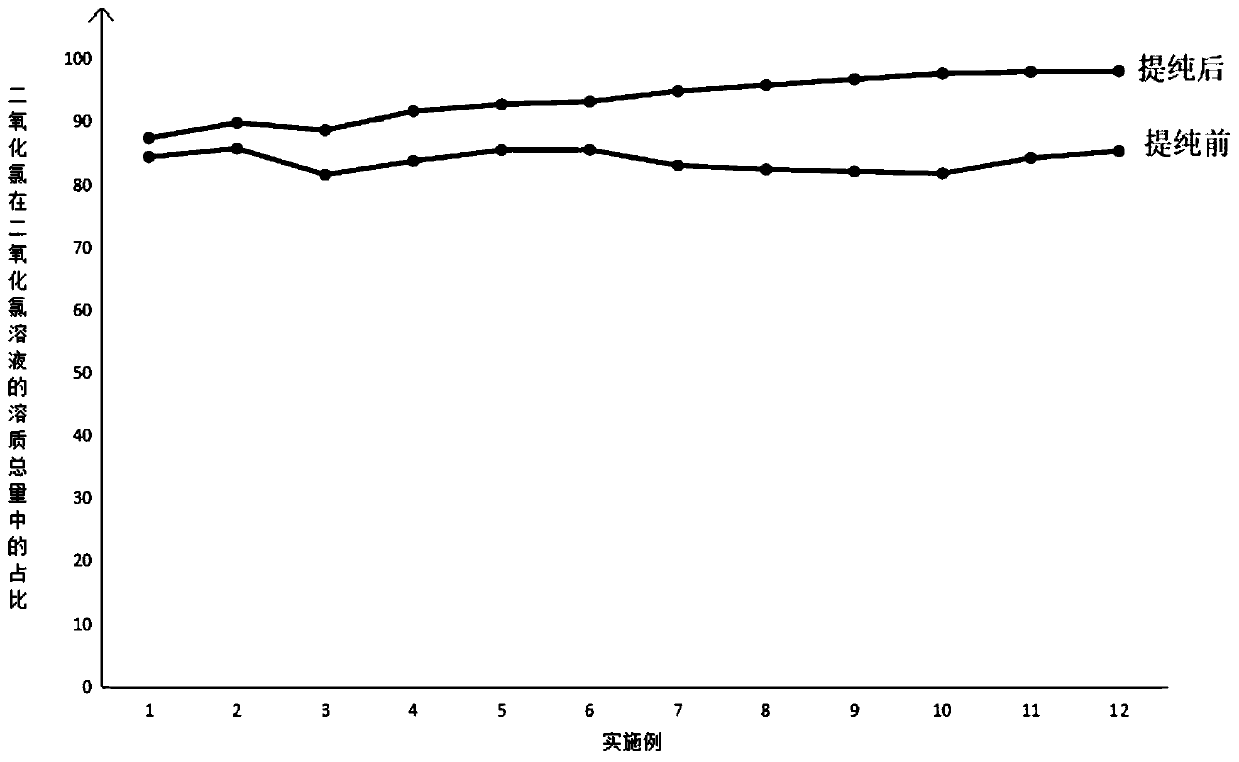

Embodiment 1

[0026] Take 100ml of chlorine dioxide solution containing chlorine gas and chlorine gas content accounting for 14.63% of the total mass of solute, put it in a glass sand core solvent filter, add hydrochloric acid with a concentration of 0.08mol / L dropwise in the solution, and adjust the pH of the solution Value is 5, then decompression suction filtration 10min makes chlorine be separated out, control suction filtration pressure is 0kPa, the temperature of solution during suction filtration is 25 ℃, after suction filtration finishes, obtain the chlorine dioxide solution after purification, in the solution after purification, The chlorine dioxide content accounts for 87.39% of the total mass of the solute; the separated chlorine gas can be collected and sent to the hydrochloric acid synthesis system for the production of hydrochloric acid;

[0027] The chlorine dioxide solution that is used for suction filtration is prepared by the R6 method, and the preparation method is as foll...

Embodiment 2

[0029] Get 200ml of chlorine dioxide solution containing chlorine gas and the chlorine gas content accounts for 12.24% of the total mass of the solute, put it in a glass sand core solvent filter, add dropwise hydrochloric acid with a concentration of 0.09mol / L in the solution, and adjust the pH of the solution The value is 4.7, and then the chlorine gas is precipitated by vacuum filtration for 12 minutes, the suction filtration pressure is controlled at -9.5kPa, the temperature of the solution during suction filtration is 23°C, and the purified chlorine dioxide solution is obtained after the suction filtration. The purified solution Among them, the content of chlorine dioxide accounts for 89.80% of the total mass of the solute; the separated chlorine gas can be collected and sent to the hydrochloric acid synthesis system for the production of hydrochloric acid;

[0030] The chlorine dioxide solution used for suction filtration is prepared by the R6 method, and the preparation m...

Embodiment 3

[0032] Get 300ml of chlorine dioxide solution containing chlorine gas and the chlorine gas content accounts for 16.41% of the total solute mass, put it in a glass sand core solvent filter, add hydrochloric acid with a concentration of 0.10mol / L dropwise in the solution, and adjust the pH of the solution The value is 4.4, and then depressurized suction filtration for 11.6min to precipitate chlorine gas, control the suction filtration pressure to -19kPa, the temperature of the solution during suction filtration is 22°C, and obtain the purified chlorine dioxide solution after the suction filtration, the purified solution Among them, the chlorine dioxide content accounts for 88.64% of the total mass of the solute; the separated chlorine gas can be collected and sent to the hydrochloric acid synthesis system for the production of hydrochloric acid;

[0033] The chlorine dioxide solution used for suction filtration is prepared by the R6 method, and the preparation method is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com