Adsorption type mine air dust-settling device

A dust suppression device and adsorption technology, which is applied in the direction of safety devices, dust prevention, mining equipment, etc., can solve the problems of time-consuming and laborious installation and movement, muddy water left on the ground, and affecting dust reduction efficiency, etc., to improve the adsorption effect and increase the dust collection range , Design novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

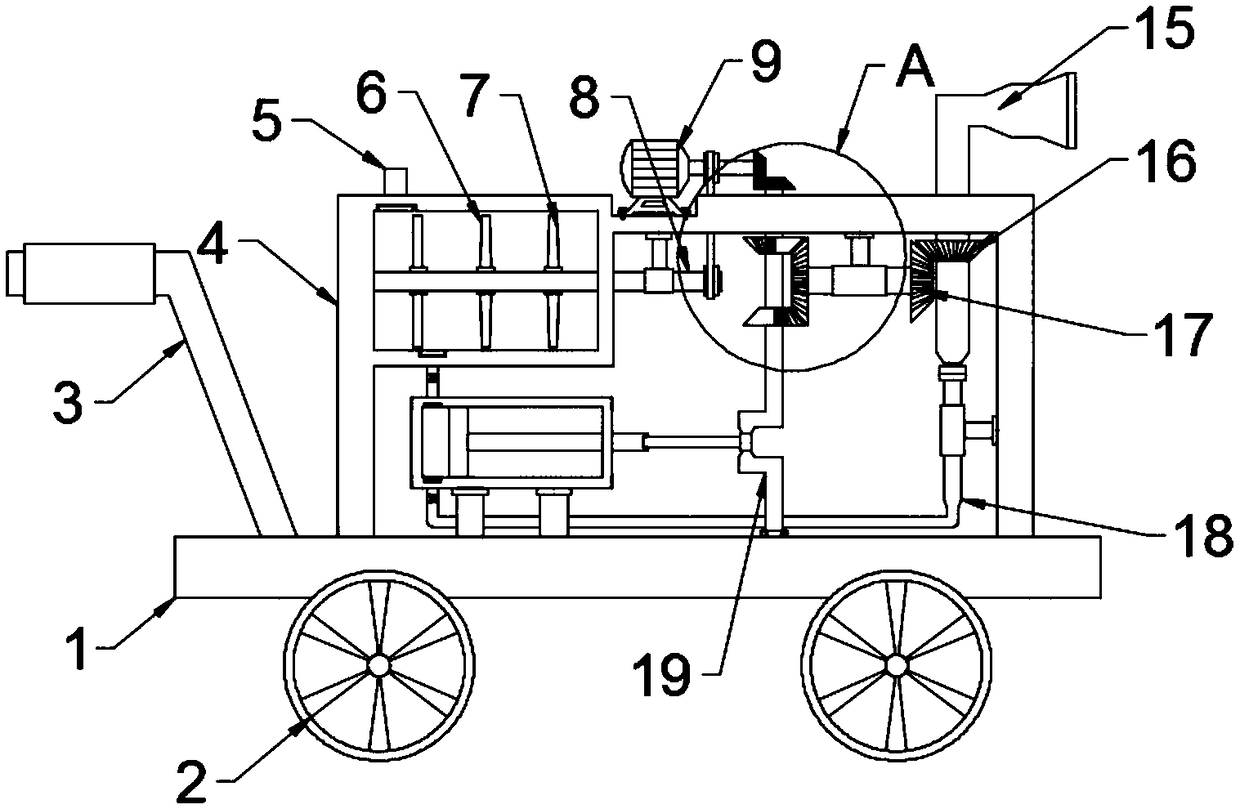

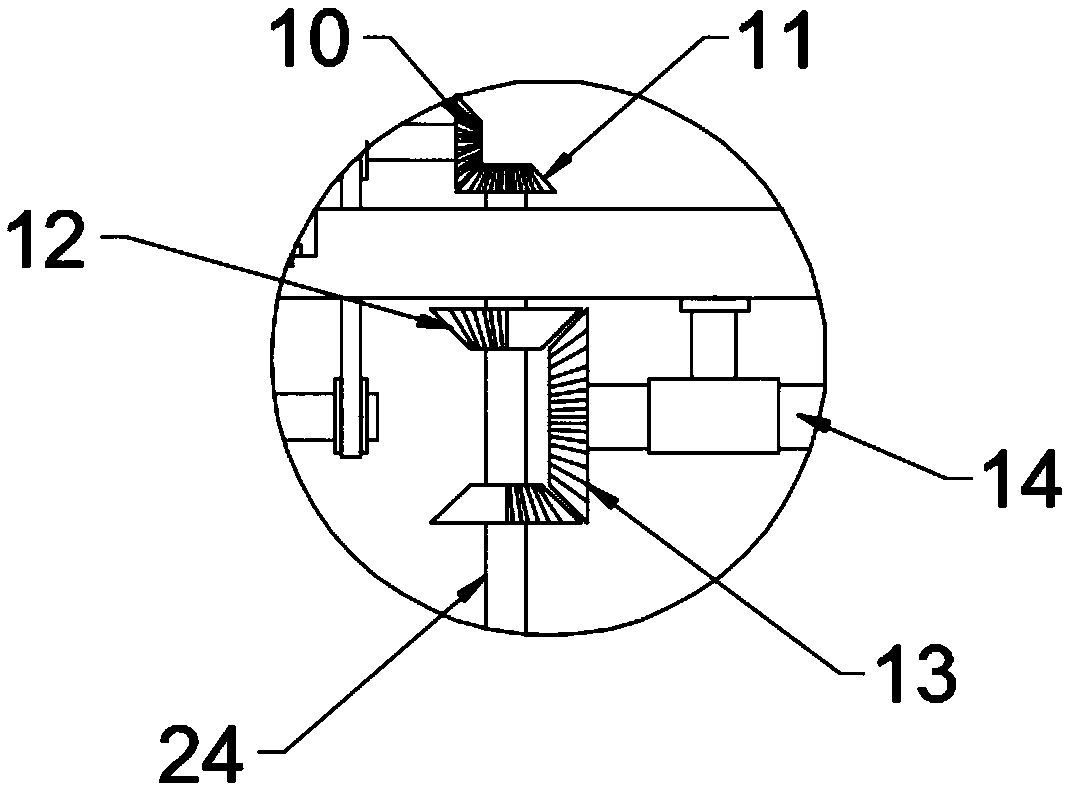

[0023] see Figure 1~3 , in an embodiment of the present invention, an adsorption type air dust suppression device for mines includes an adsorption chamber 4, a dust cover 15, a transmission chamber 18 and a pumping mechanism; the transmission chamber 18 is fixedly installed on the upper end of the bottom plate 1, and the adsorption chamber 4 is set At the upper end of the transmission chamber 18, the upper end of the transmission chamber 18 is also provided with a dust collection cover 15, the dust collection cover 15 is L-shaped, and its upright end penetrates the upper wall of the transmission chamber 18 into the transmission chamber 18 and is connected with the transmission chamber 18. The upper wall of the upper wall is rotatably connected, and a bevel gear D16 is fixedly installed on the dust collection cover 15 in the transmission chamber 18. The bevel gear D16 meshes with the bevel gear E17 fixedly installed on the right end of the second rotating rod 14. The second rot...

Embodiment 2

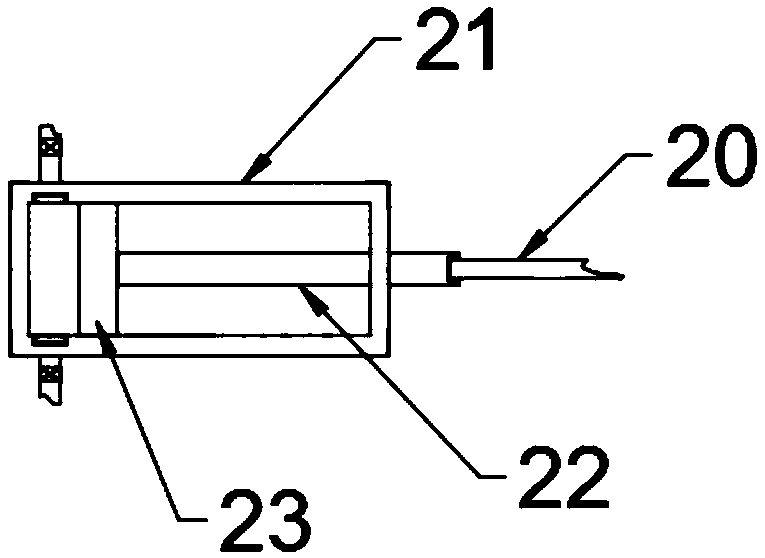

[0029] see Figure 2~5 The difference between the second embodiment and the first embodiment is that the other end of the connecting rod 20 is rotatably connected to the eccentric position of the turntable 25, and the rear end shaft of the turntable 25 is engaged with the first bevel gear F26 and the bevel gear G27 through the meshing action. The three rotating rods 24 are connected in rotation, the bevel gear F26 is fixedly connected to the turntable 25 , and the bevel gear G27 is fixedly connected to the third rotating rod 24 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com