Efficient unhusked rice dryer

A paddy dryer and high-efficiency technology, which is applied in the agricultural field, can solve the problems of inability to dry grains, decreased quality of grain raw materials, and low drying efficiency, and achieve the effects of enhancing drying effect, improving efficiency, and reasonable and sufficient structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described in detail below in conjunction with specific embodiments.

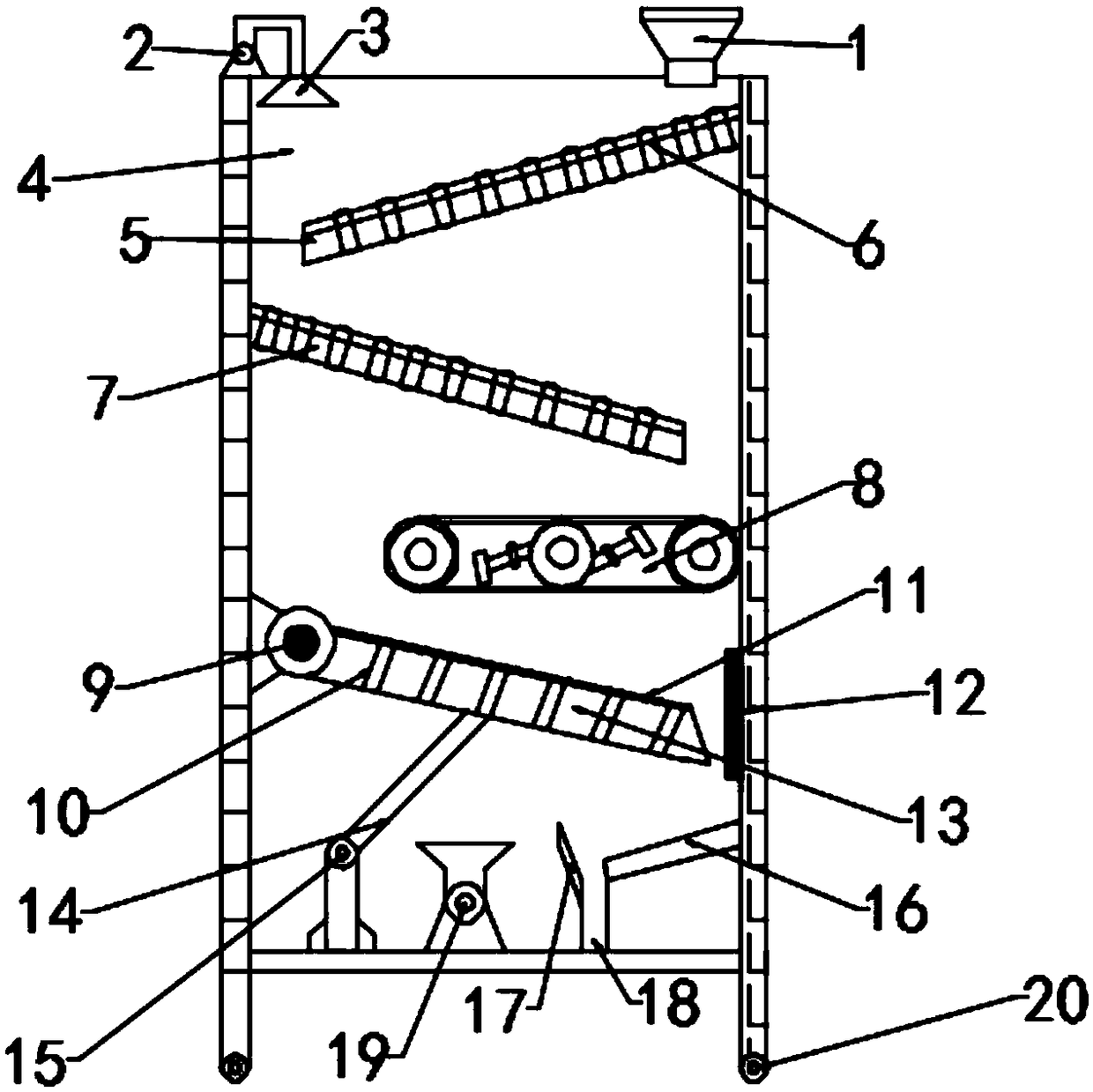

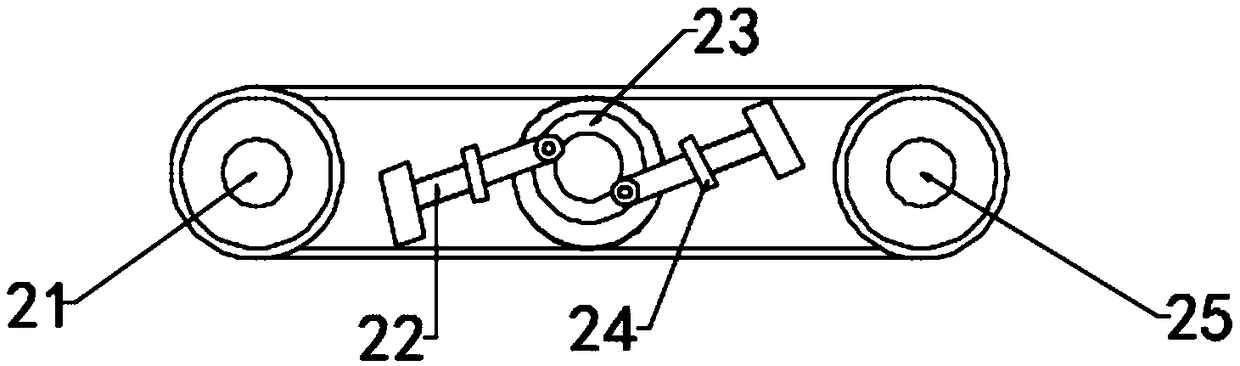

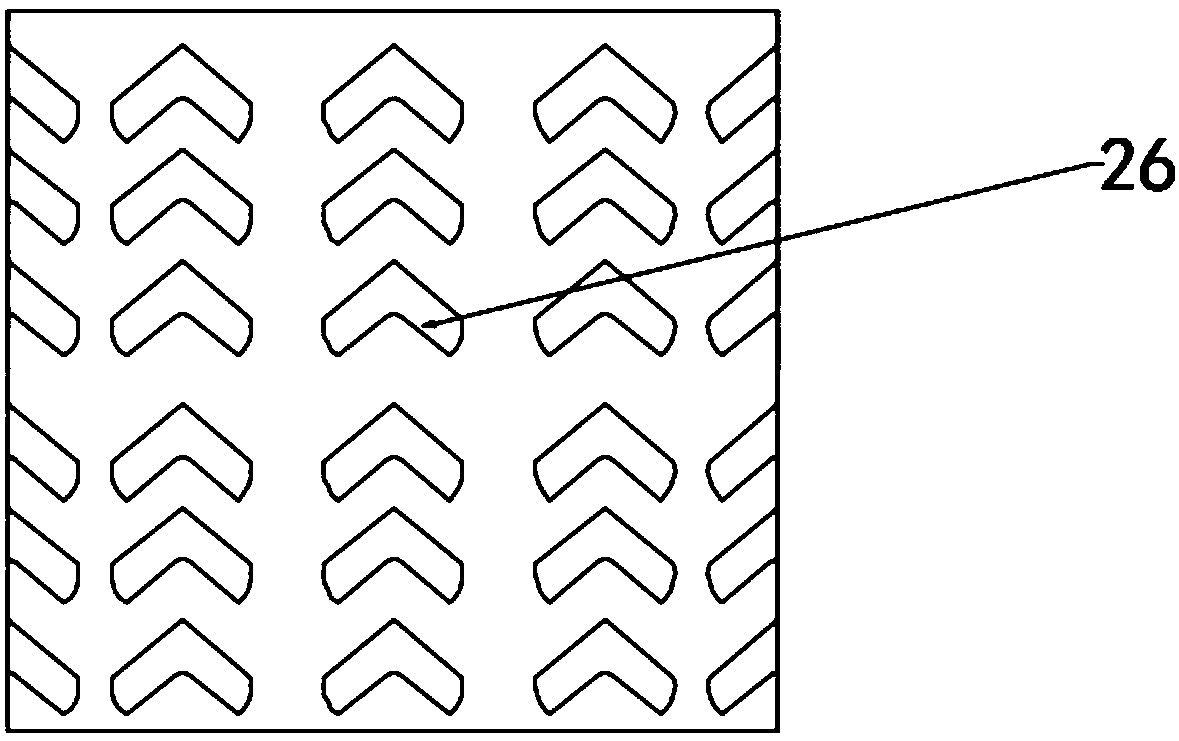

[0016] See Figure 1-3 , An efficient rice drying machine, which includes: hot air blower-2, feed hopper 1, hot air blower-2 and feed hopper 1 are jointly connected to the drying box 4, and the wheels 20 installed at the bottom of the drying box 4 , The hot air blower 2 is connected to the horn-shaped air outlet 3 through the pipeline, the hot air blower 2 is installed on the left side of the drying box 4, and the feed hopper 1 is installed on the right side of the drying box 4, and the drying box 4 is the core part of the whole device , The drying box 4 is provided with two baffles, the first baffle 5 and the second baffle 7, respectively. The first baffle 5 is drilled with vent holes -6, and the number of vent holes is 6. There are 10, and the diameter of the vent-6 is smaller than the diameter of the rice. The second baffle 7 is also dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com