Efficient torreya grandis circulating drying device and drying method thereof

A drying device and technology of torreya, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of high labor intensity, inability to independently process torreya, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

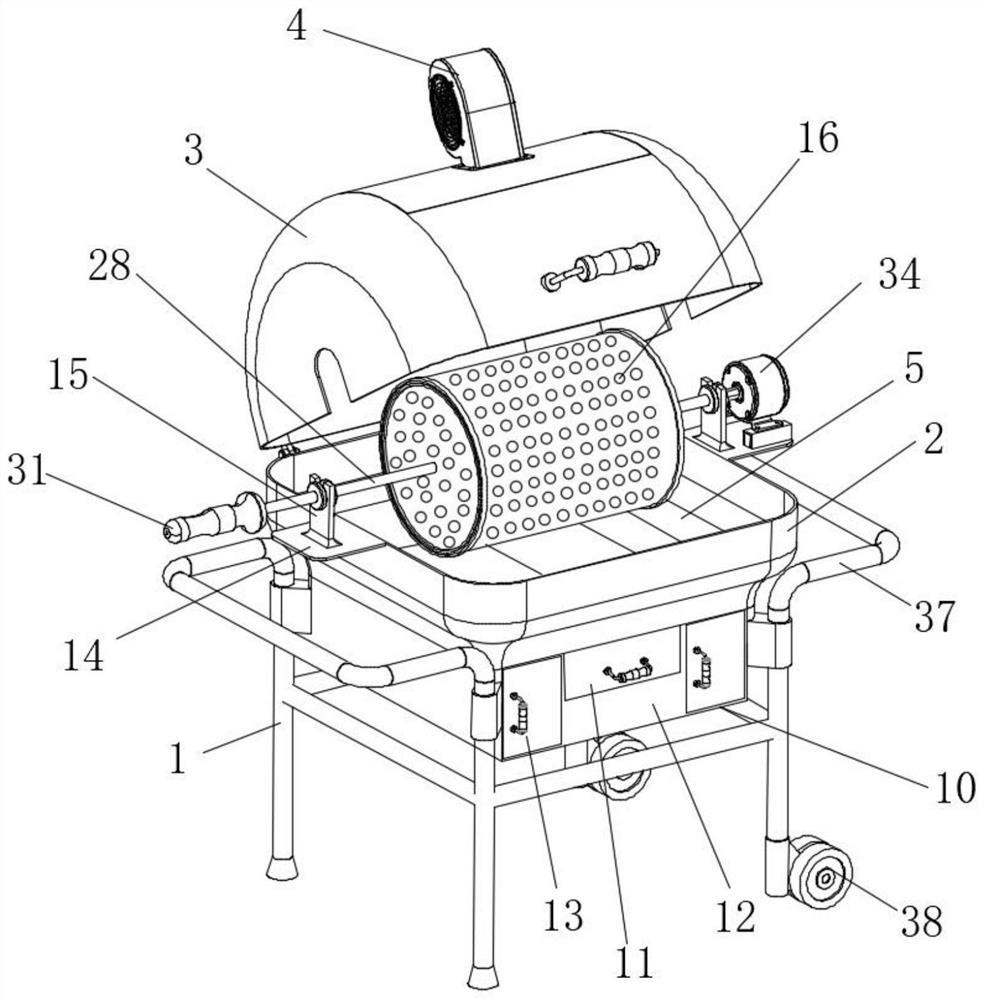

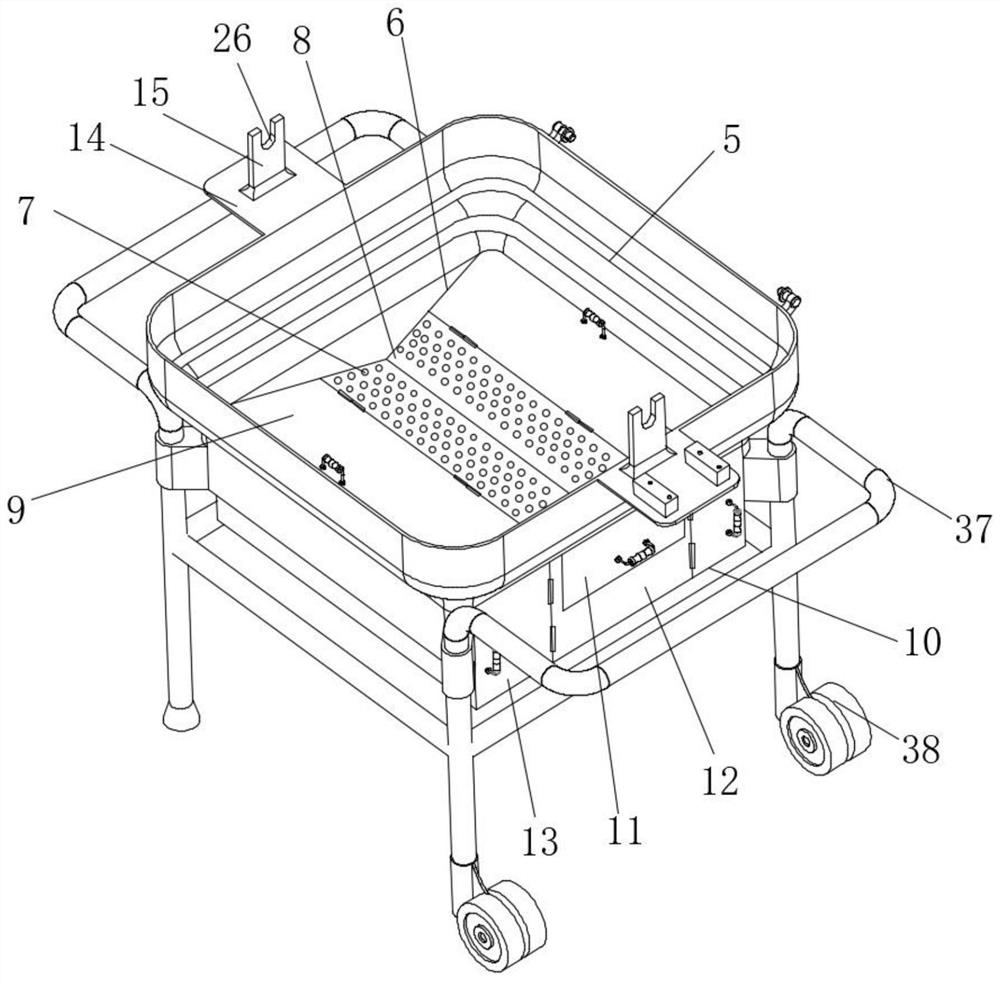

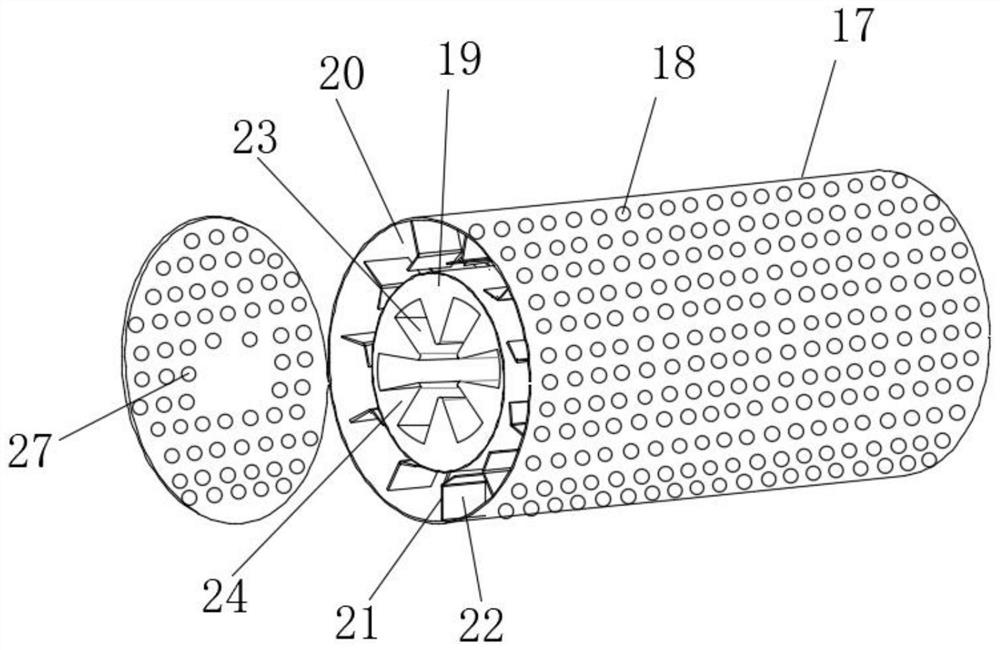

[0023]EXAMPVI: A high-efficiency fragrant cycle drying device, such asFigure 1-2As shown, including the frame body 1, the frame body 1 is provided with a drying chamber 2, and the drying chamber 2 is rotated, and a blower 4 is provided at the top of the drying cover 3; in the drying cover 3 When the drying chamber 2, the air inlet of the blower 4 is facing down; the side wall of the drying chamber 2 is provided with a heating tube 5, and the heating tube 5 is disposed on the side wall of the drying chamber 2; The drying chamber 2 is provided with a V-shaped drying bottom wall 6, and the middle portion of the drying bottom wall 6 is a fixed plate 8 having a plurality of first vent hole 7, and the outer side of the drying bottom wall 6 is with a fixed plate. 8 hinged flip plate 9, the fixing plate 8 and the flip plate 9 are connected between the hinged pages, and can be rotated; the lowering of the drying chamber 2 is provided with a heat exchange chamber 10, including the heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com