Firework charging production line

A production line and charging technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of complicated fireworks production process, numerous processes, raw material mixing uniformity, proportioning quality and production speed, etc., to achieve The quality assurance of mixing uniformity and proportioning, and the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

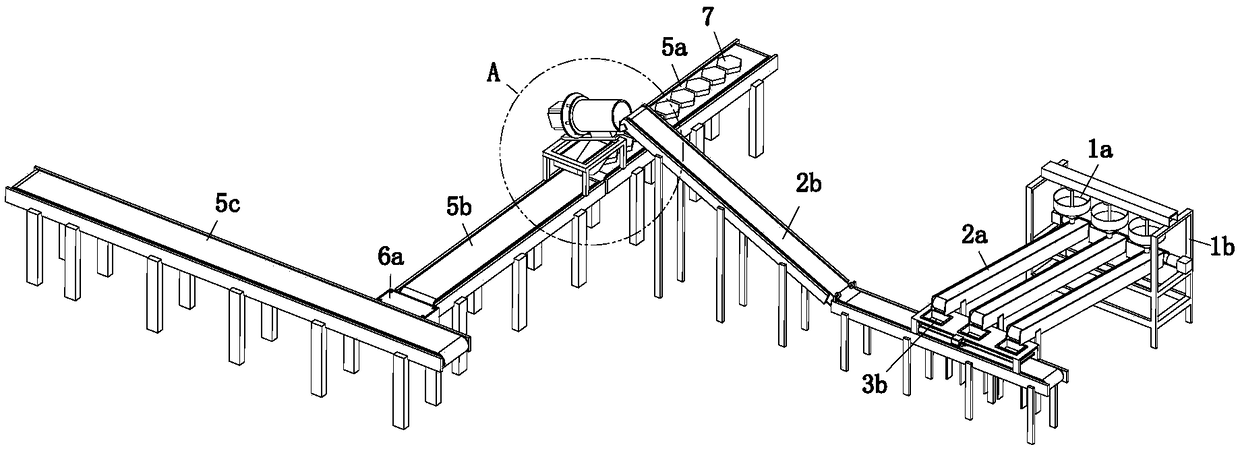

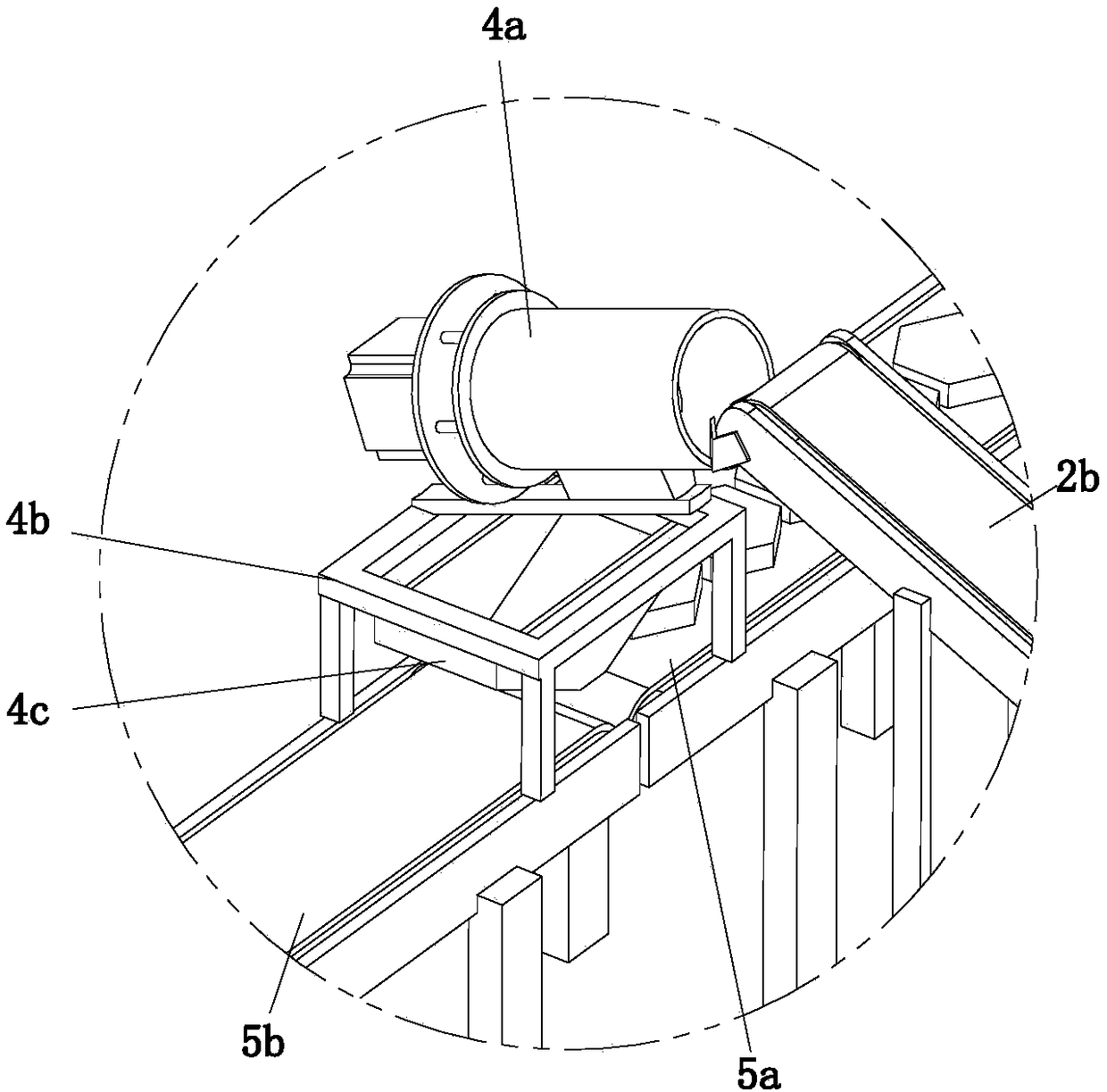

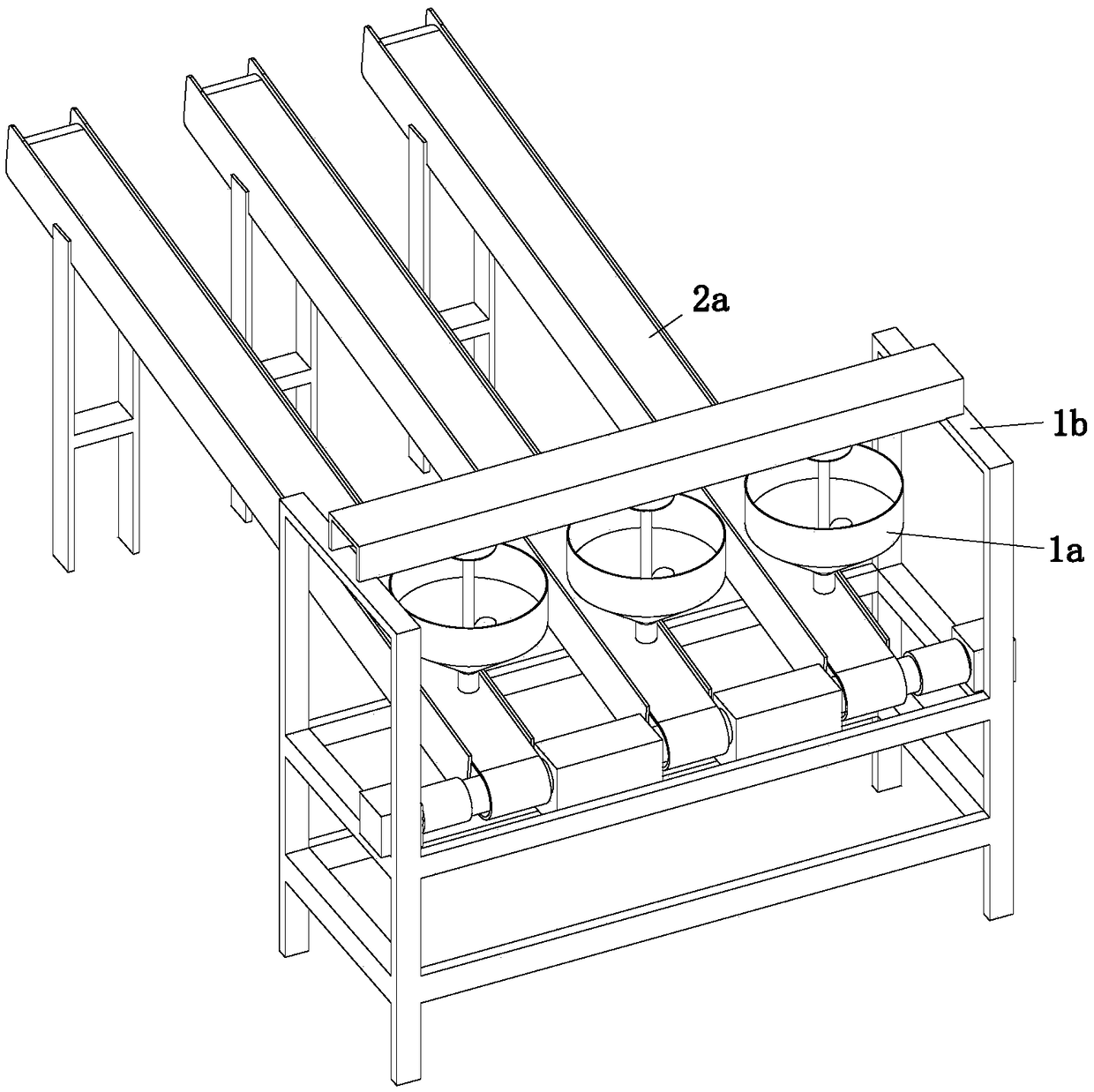

[0029] refer to Figure 1 to Figure 11 The shown a kind of fireworks charge production line, comprises feeding mechanism, proportioning mechanism, filling mechanism, raw material conveying mechanism and pie crust conveying mechanism, and described feeding mechanism comprises a plurality of agitating cylinders 1a arranged side by side, and proportioning mechanism It is connected with a plurality of mixing cylinders 1a through a raw material transmission mechanism, and the raw material transmission mechanism is also connected with the filling mechanism. The filling mechanism is installed directly above the cake skin transmission mechanism, and the cake skin 7 moves on the cake skin transmission mechanism. The filling mechanism charges it.

[0030] Preferably, the present invention also includes a plurality of explosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com