Method for determining air leak holes, vacuum motor and method for detecting article adsorbed by vacuum motor

A technology of a vacuum motor and a determination method, which is applied to the detection of vacuum motors and their adsorbed objects, and the determination of air leakage holes, can solve the problem of the adsorption of objects by the motor, the difficulty of setting the current change threshold, and the difficulty of correctly judging whether the vacuum motor really adsorbs objects, etc. problem, to achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

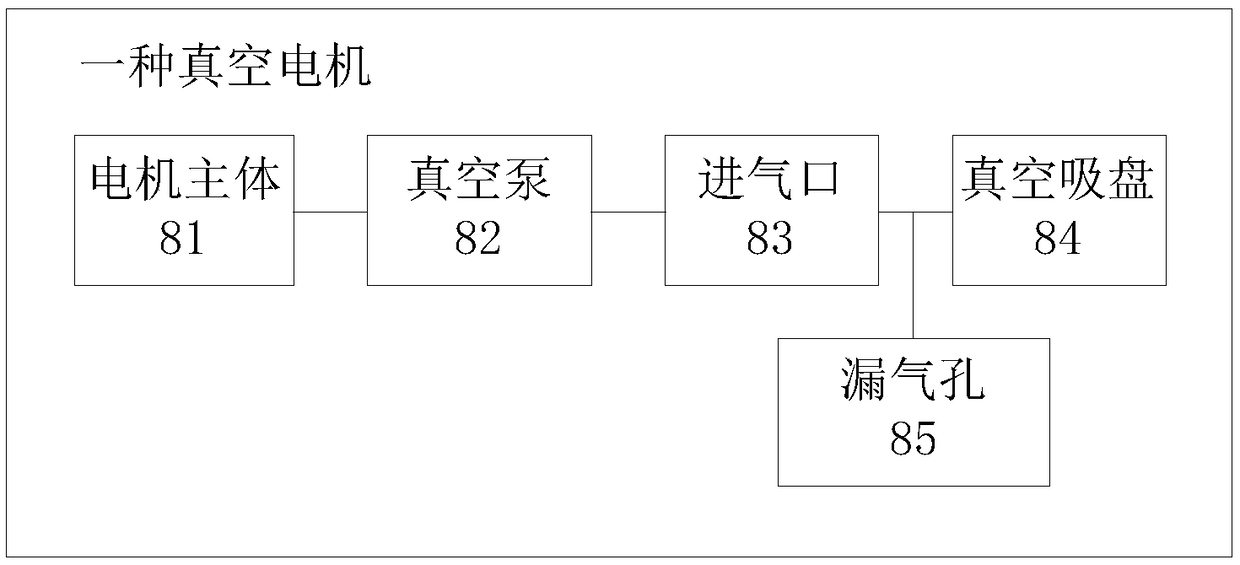

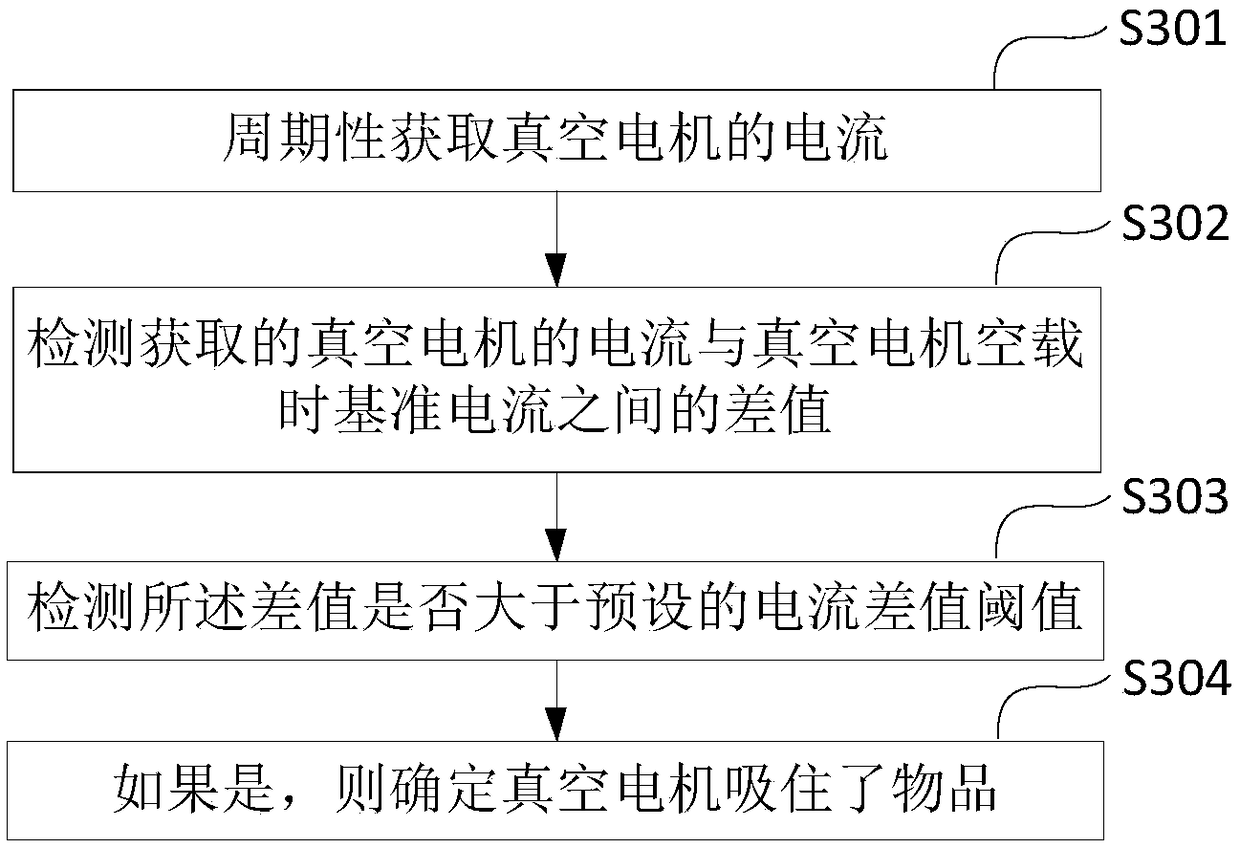

[0113] According to the above description, the present application also provides an embodiment of a method for determining an air leak, a vacuum motor and a method for detecting its adsorbed articles, including a medicine dispensing device, the medicine dispensing device is equipped with a main board, a vacuum motor , vacuum manipulator, etc., wherein the main board, vacuum motor, and vacuum manipulator are connected by data signal lines, and the end of the vacuum manipulator is provided with a vacuum suction cup, which is used to absorb medicines.

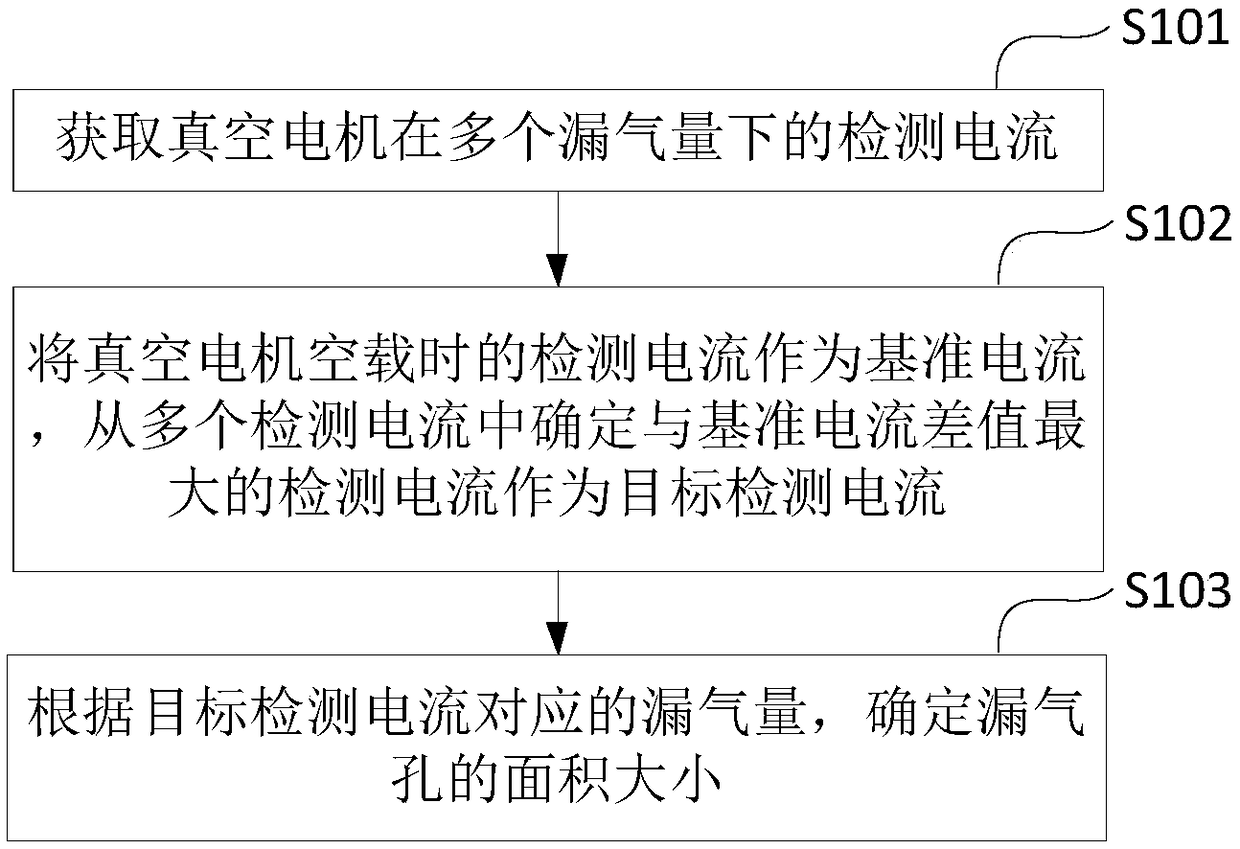

[0114] Apply a method for determining an air leak hole, a vacuum motor and its adsorbed article detection method provided in the embodiment of the present application to the medicine dispensing device, and obtain the detection current of the vacuum motor of the medicine dispensing device under multiple air leakage amounts, Then determine the detection current with the largest difference from the reference current when the vacuum mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com