Device and method for measuring fiber permeability of flat plate preform

A technology of preforms and measuring devices, which is applied in the directions of measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc. It can solve problems such as single function, cost waste, and complicated measurement methods, so as to avoid cost waste , easy operation, and simple measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

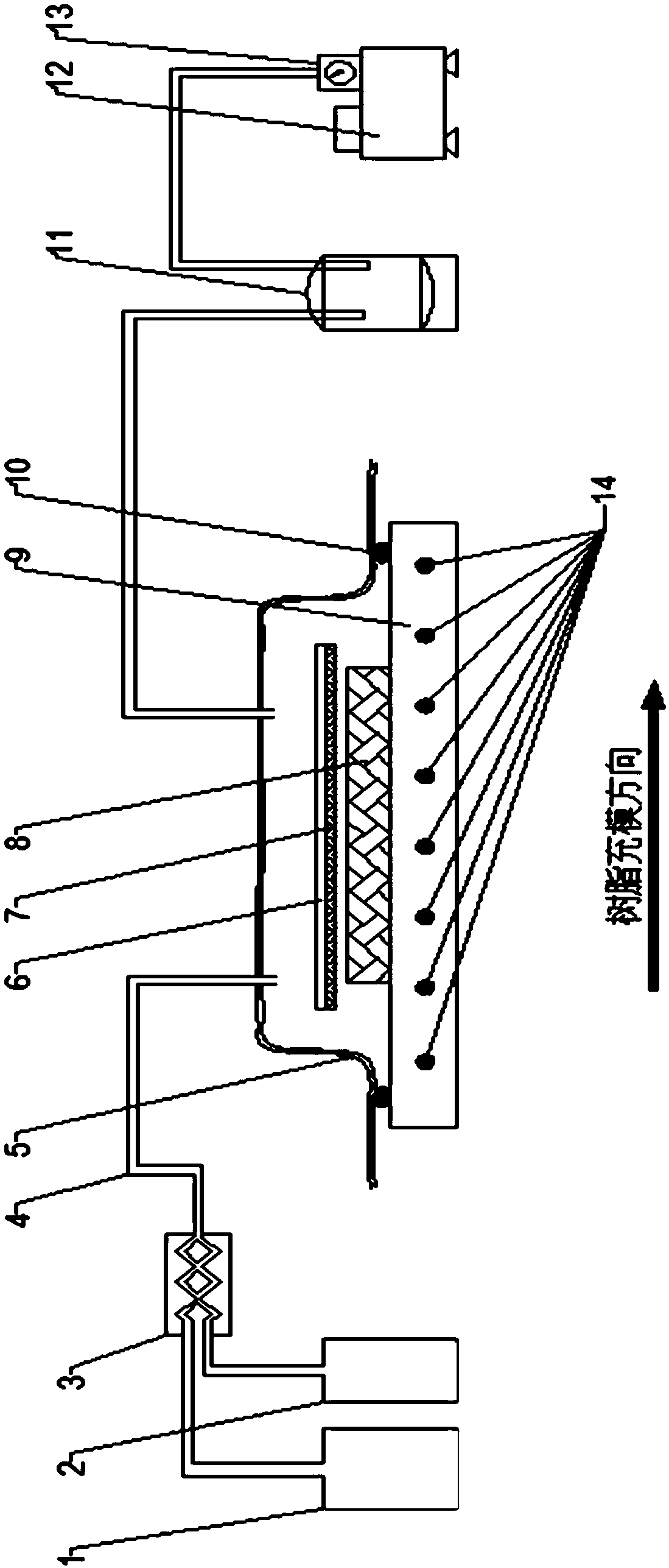

[0022] combine figure 1 Describe this embodiment, in this embodiment, a kind of measuring device that is used for the fiber permeability of flat plate preform that the present invention relates to, it comprises resin tank 1, catalyst tank 2, static mixer 3, resin tube 4, Vacuum bag film 5, diversion net 6, release cloth 7, fiber preform 8, mold 9, sealing tape 10, resin recovery tank 11, vacuum pump 12, sensor 14, No. 1 conduit and No. 2 conduit; the resin tank 1 and the outlet of the catalyst tank 2 are respectively connected with the two inlets of the static mixer 3, the sealing tape 10 seals the vacuum bag film 5 on the mold 9 and forms a sealed space, and the outlet of the static mixer 3 passes through the resin tube 4 communicates with the sealed space, a plurality of sensors 14 are arranged on the mold 9, the guide net 6, the release cloth 7 and the fiber preform 8 are all arranged in the sealed space, the fiber preform 8, the release cloth 7. The diversion net 6 is pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com