Calibration method for on-line total chromium analyzer

A calibration method and analyzer technology, which is applied in the direction of color/spectral characteristic measurement, etc., can solve the problems that no similar instrument research has been carried out, and there is no online total chromium analyzer verification procedure or calibration specification, etc., and achieve the effect of correcting inherent errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

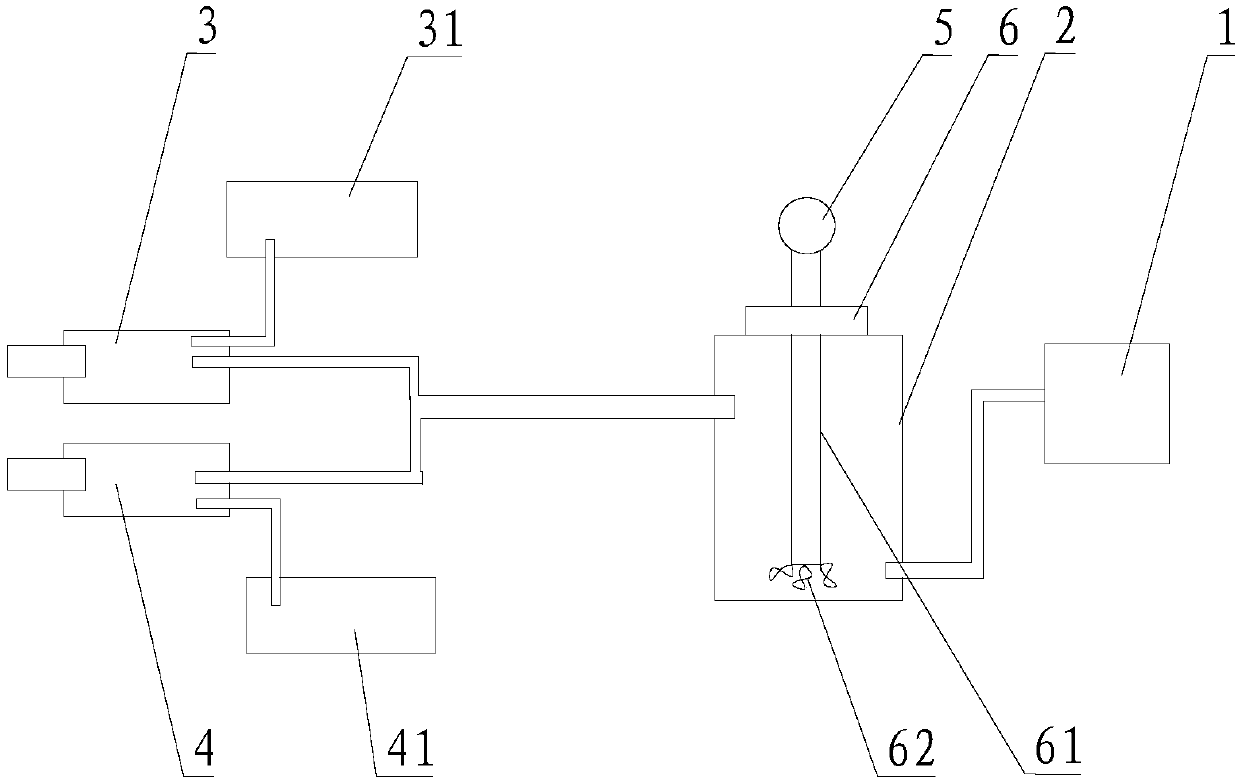

[0044] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0045] The calibration method of the on-line total chromium analyzer of this embodiment, the calibration method is calibrated based on the calibration device, and the calibration device includes the on-line total chromium analyzer 1, a host computer, a first control module, a second control module, a third Control module, circuit control unit, solution mixing device 2, first syringe pump 3, second syringe pump 4, peristaltic pump 5 and electromagnetic stirrer 6; the injection inlet of the first syringe pump 3 is connected to the pipeline of standard mother solution bottle 31 The injection inlet of the second syringe pump 4 is communicated with the diluent bottle 41 pipeline, and the injection outlets of the first syringe pump 3 and the second syringe pump 4 are respectively communicated with the liquid inlet pipeline of the solution mixing device 2 A liquid outlet of the solution mixing device 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com