Method of readjusting a pressure sensor in an engine air intake line, as a function of temperature

A technology of pressure sensor and calibration method, which is applied in the direction of engine control, machine/engine, electrical control, etc., to achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

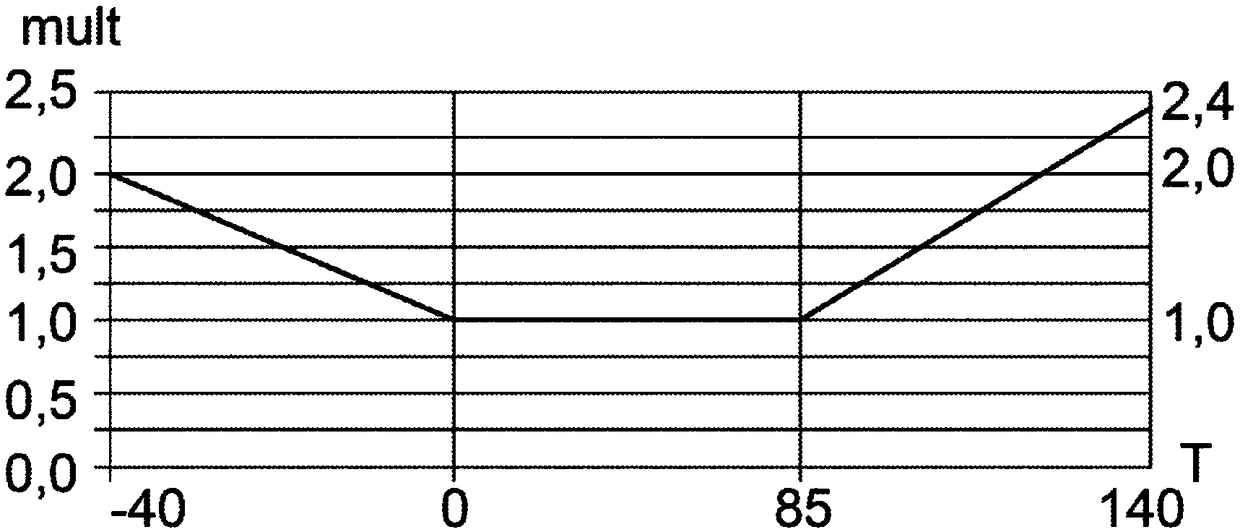

[0053] figure 1 It has been described in the introductory part of the present invention.

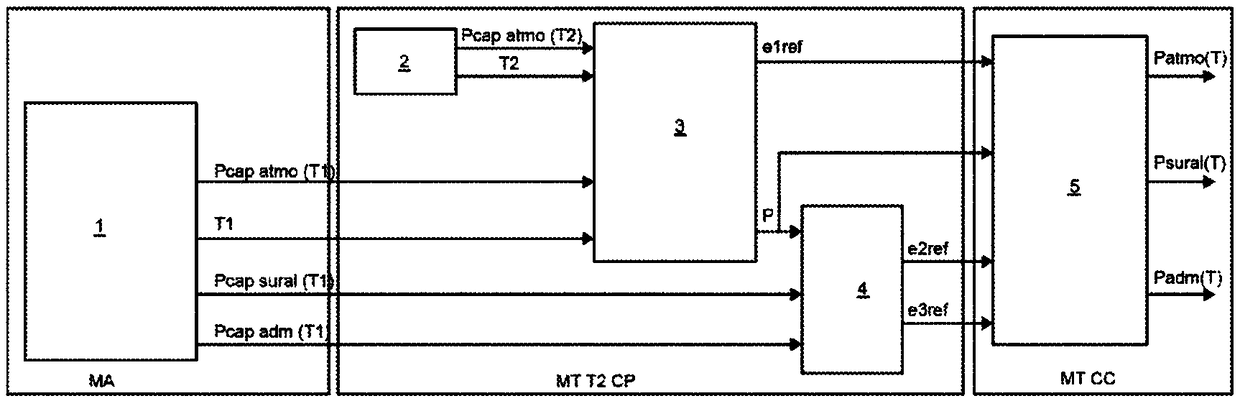

[0054] refer to figure 2 , shows a logic diagram of the calibration method for at least three sensors, namely barometric pressure sensor, boost sensor and intake sensor air. These pressure sensors may all be present in the intake line of the internal combustion engine, which is advantageously a spark ignition engine.

[0055] The boost sensor may be located downstream of a turbocharger compressor of the internal combustion engine, and the intake sensor may be located in an air distributor inlet of the internal combustion engine.

[0056] However, as previously stated, it should be noted that the invention can be applied to only one pressure sensor or to a different number of pressure sensors than three, for example not using a boost sensor when the engine is not a turbocharger. Likewise, other pressure sensors than the aforementioned sensors may be considered.

[0057] In the case o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com