Battery internal resistance measuring method and device for vehicle

A technology of battery internal resistance and measurement method, which is applied in the direction of measuring device, measuring electricity, measuring electric variable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] for car batteries

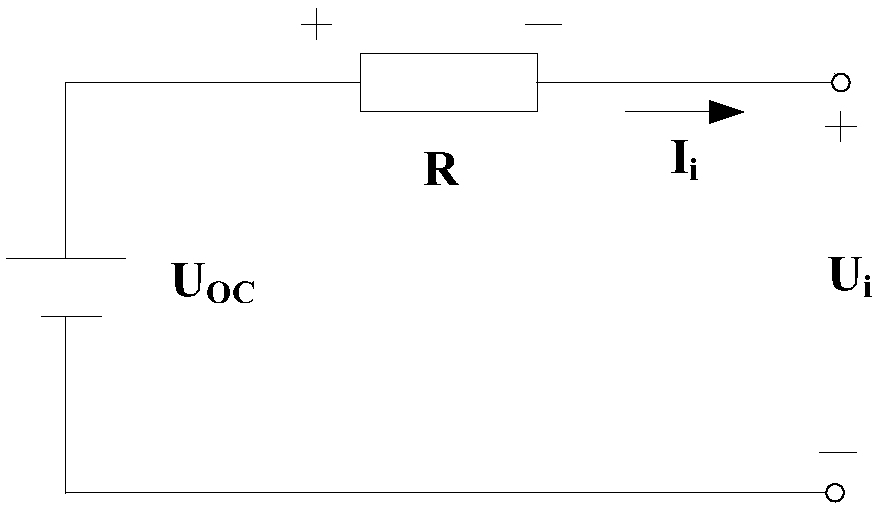

[0064] See figure 1 as shown, figure 1 It is a schematic diagram of the circuit structure of a vehicle battery unit to be tested in this embodiment, wherein U OC R is the power supply electromotive force of the vehicle battery unit to be tested. The power supply electromotive force is a fixed value. R is the internal resistance of the vehicle battery unit to be tested. It should be noted that, generally speaking, the internal resistance of the power supply is not A constant value, usually, the internal resistance of the power supply is related to the current or voltage passing through the power supply, U i is the external apparent voltage of the vehicle battery unit to be tested, that is, the road terminal output voltage of the vehicle battery unit to be tested, and is used to supply power to the load connected to the vehicle battery unit to be tested, I i In order to flow the current of the internal resistance of the vehicle battery unit to be te...

Embodiment 2

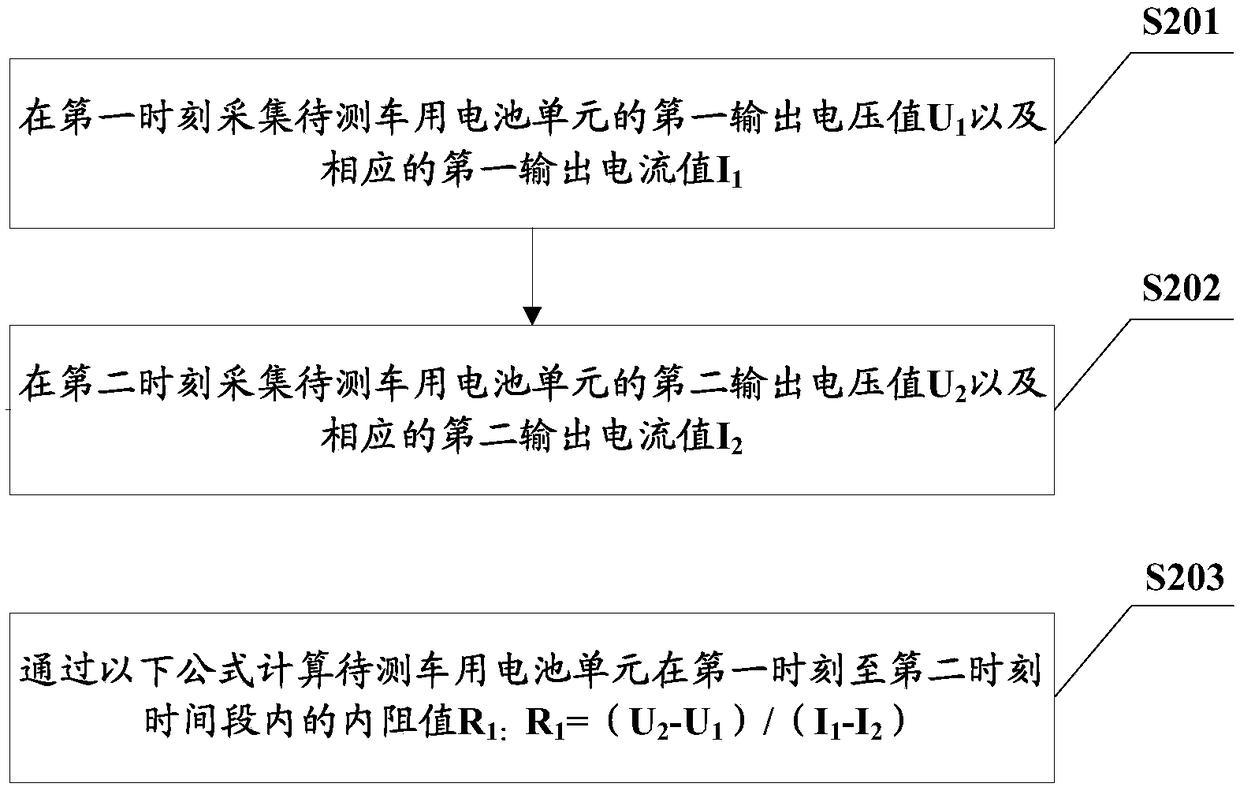

[0111] See Figure 6 As shown, this embodiment provides a vehicle battery internal resistance measurement device, including a collection module 61 and a calculation module 62, wherein the collection module 61 is used to collect the first output voltage value of the vehicle battery unit to be tested at the first moment u 1 and the corresponding first output current value I 1 , and collect the second output voltage value U of the vehicle battery unit to be tested at the second moment 2 and the corresponding second output current value I 2 ; The calculation module 62 is used to pass the formula "R 1 =(U 2 -U 1 ) / (I 1 -I 2 )” to calculate the internal resistance value R of the vehicle battery unit to be tested in the time period from the first moment to the second moment 1 , the function of the acquisition module 61 in this embodiment can be realized by constructing corresponding peripheral circuits.

[0112] It should be understood that the second moment in this embodime...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap