A multi-purpose aircraft external store automatic mounting system and method

A technology for mounting systems and external objects, applied in computer parts, image data processing, instruments, etc., can solve problems such as inability to adapt to low space, poor equipment compatibility, and large installation errors, so as to improve reliability and safety , Simplify design difficulty, improve the effect of intelligence and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

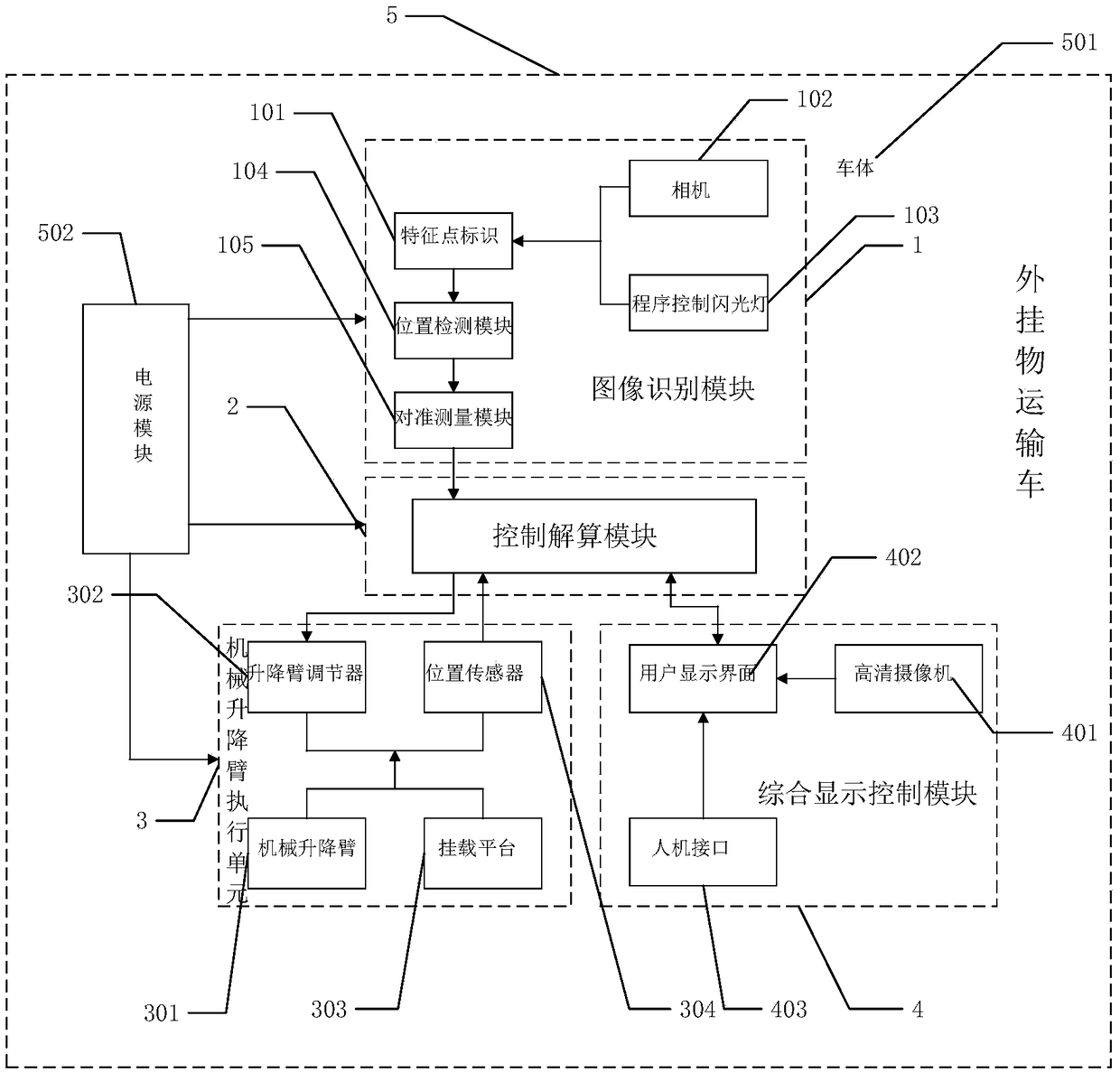

[0067] The invention is an automatic loading system for multi-purpose aircraft external hanging objects, such as figure 1 As shown, it is composed of an image recognition module 1, a control and calculation module 2, a mechanical lifting arm execution unit 3, a comprehensive display control module 4, and an external cargo transport vehicle 5, etc.

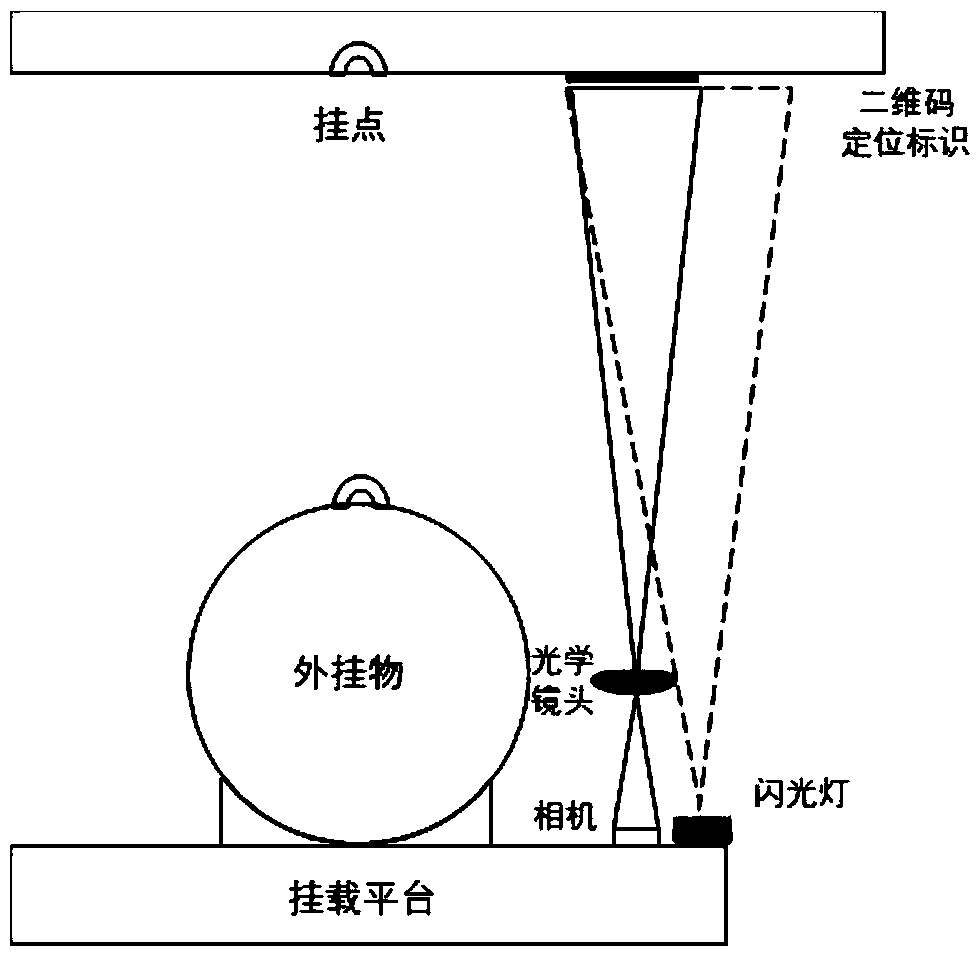

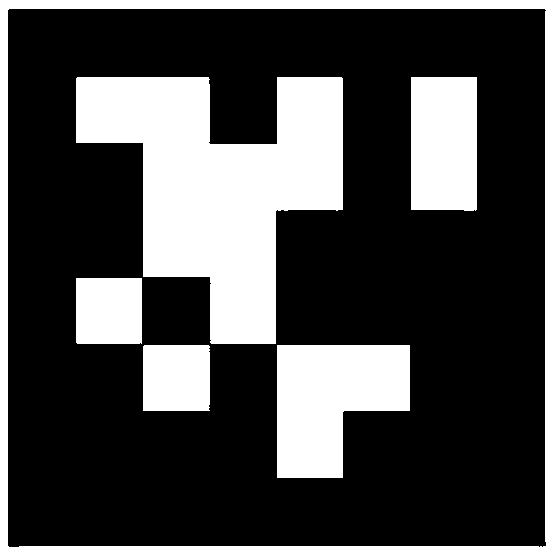

[0068] The image recognition module 1 is used to measure the relative spatial position between the external object and the point to be mounted, and transmit it to the control solution module 2 as an error control signal; the control solution module 2 completes information processing and control parameter calculation according to the error control signal , and generate the corresponding control command signal to drive the mechanical lift arm execution unit 3; the mechanical lift arm execution unit 3 ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com