Stationary part, motor, and method of manufacturing the motor

A technology for stationary parts and motors, applied in the direction of electrical components, electromechanical devices, windings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

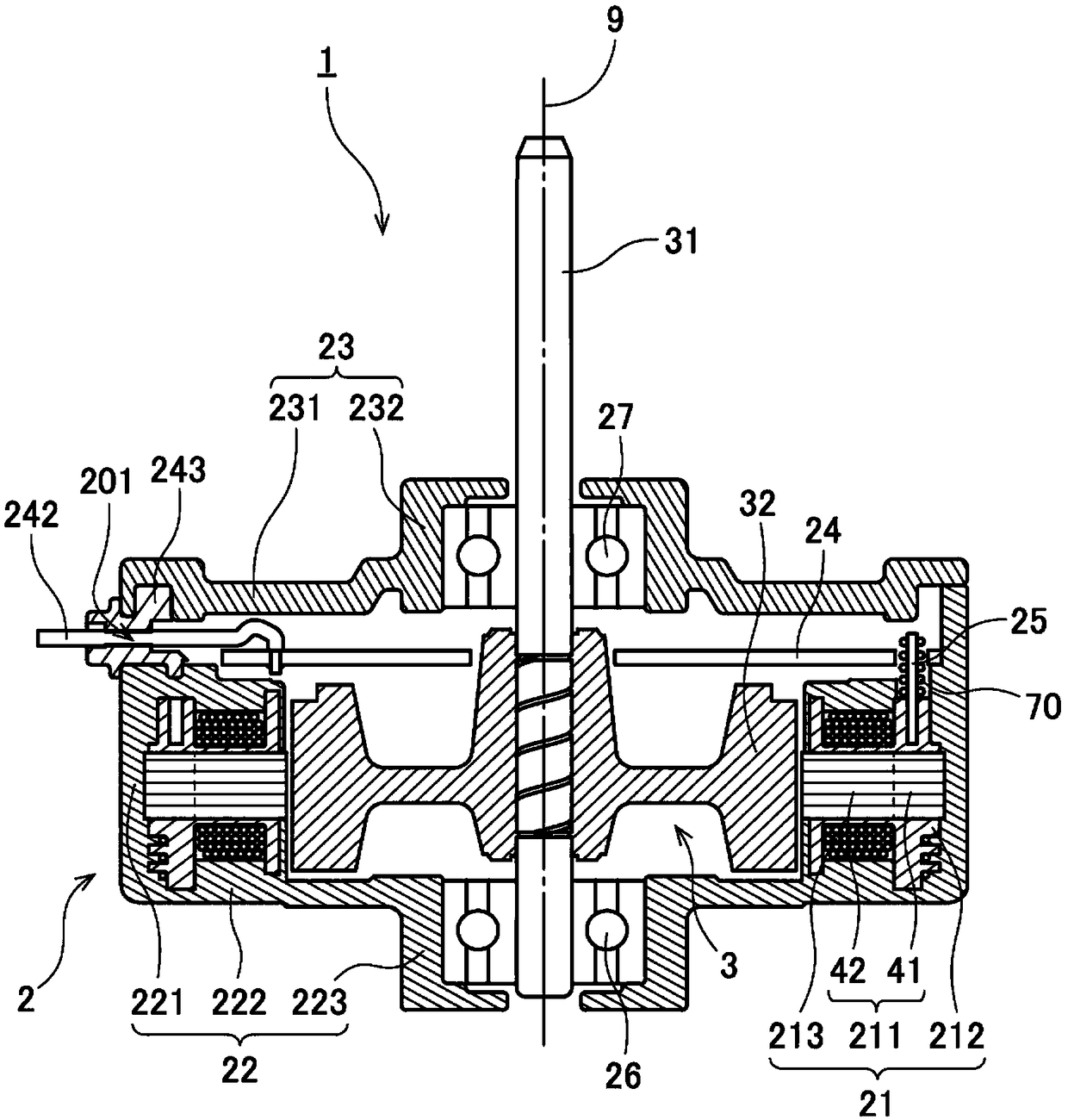

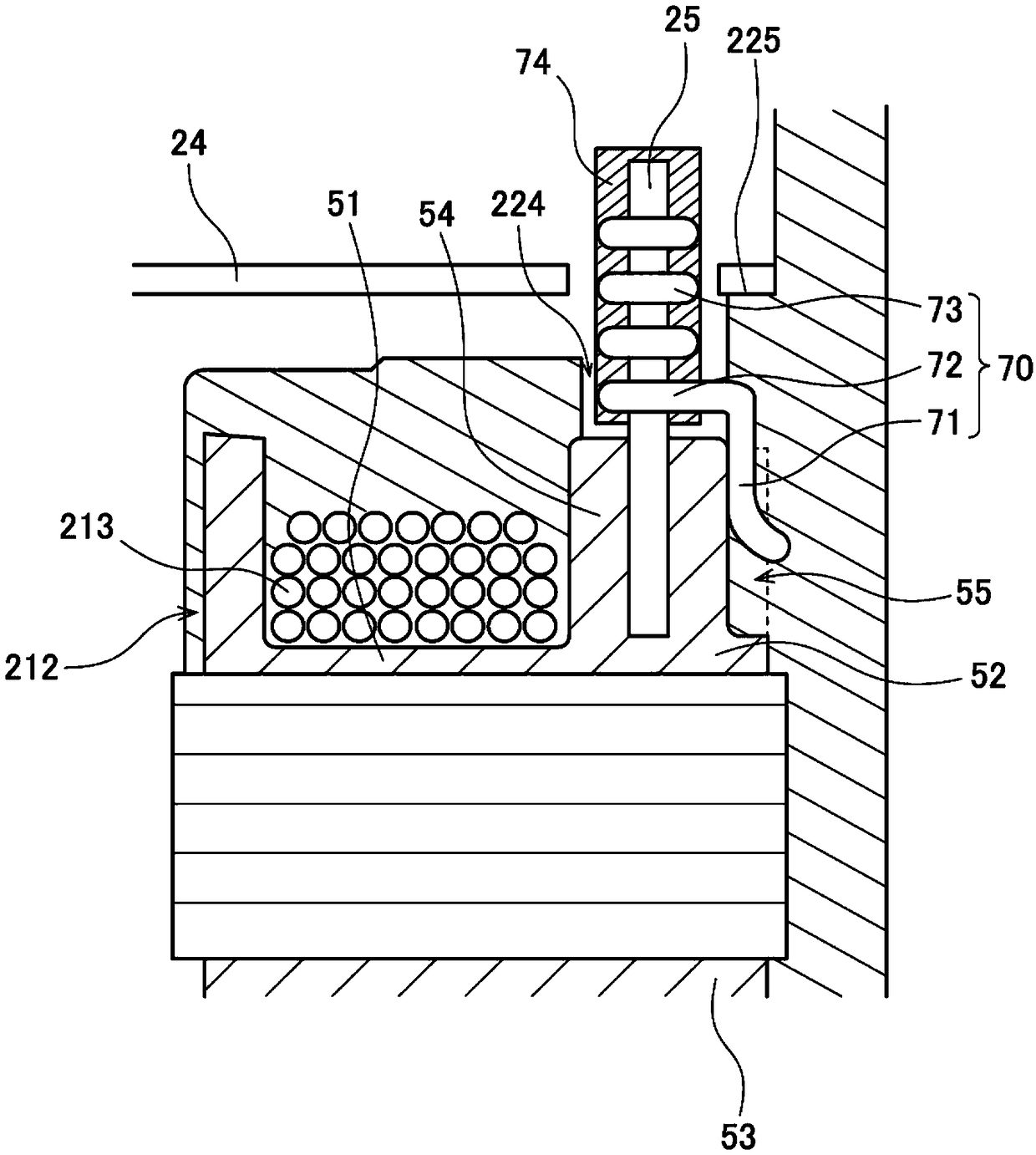

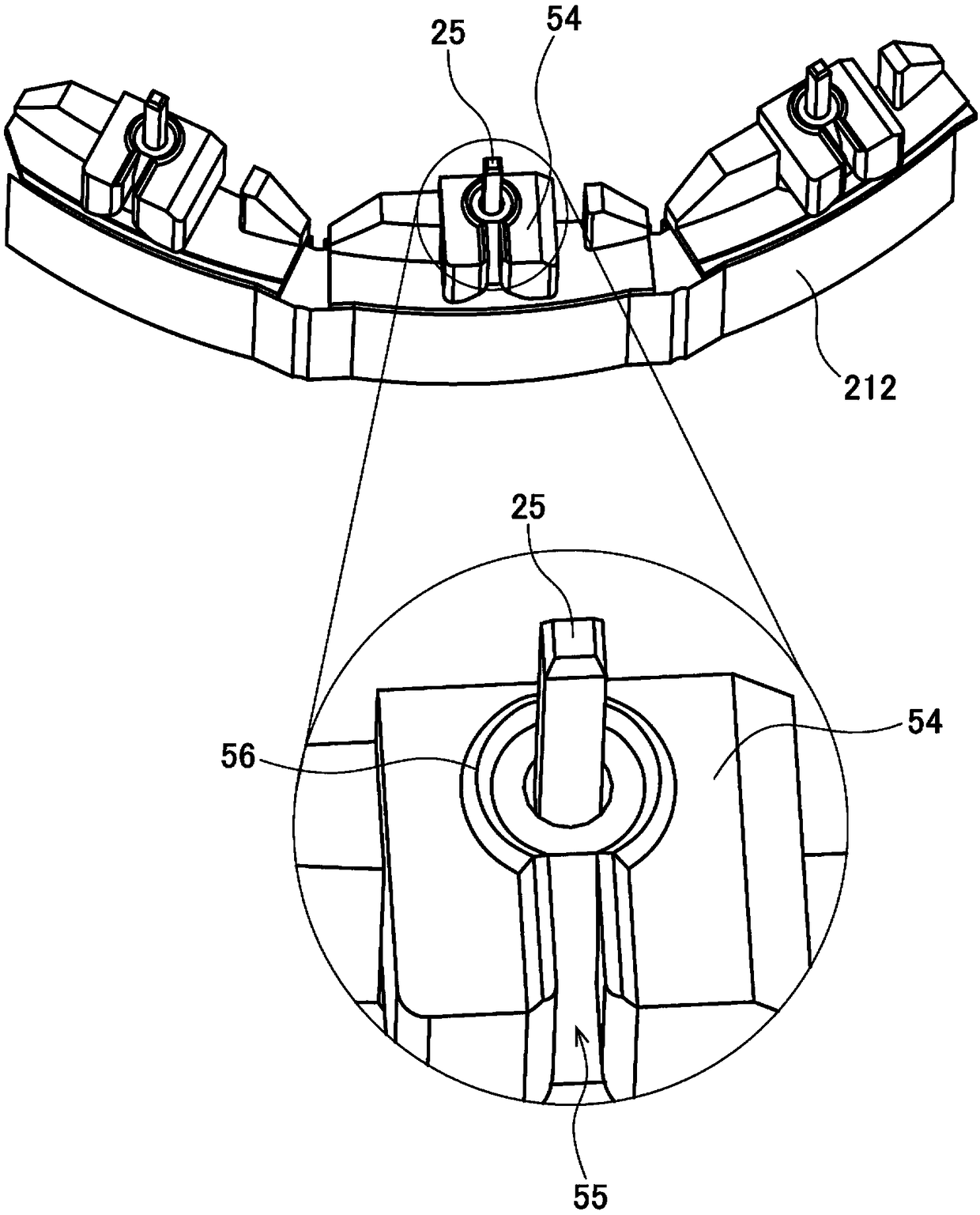

[0019] Below, while referring to the attached Figure 1 Exemplary embodiments of the present invention will be described. In addition, in this application, the direction parallel to the central axis of the motor is referred to as "axial direction", the direction perpendicular to the central axis of the motor is referred to as "radial direction", and the direction along the central axis of the motor is referred to as "radial". The direction of the arc is referred to as "circumferential". In addition, in this application, the shape and positional relationship of each part are demonstrated using the axial direction as an up-down direction, and the terminal pin side as an upward direction with respect to a stator core. However, the definition of the up-down direction is not intended to limit the orientation when manufacturing and using the motor of the present invention.

[0020] figure 1 is a longitudinal sectional view of the motor 1 . This motor 1 is a so-called inner rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com