Method and device for cleaning and/or replacement of a laser window of a process chamber

A laser window, processing chamber technology, applied in laser welding equipment, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem that the modified atmosphere cannot be maintained, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

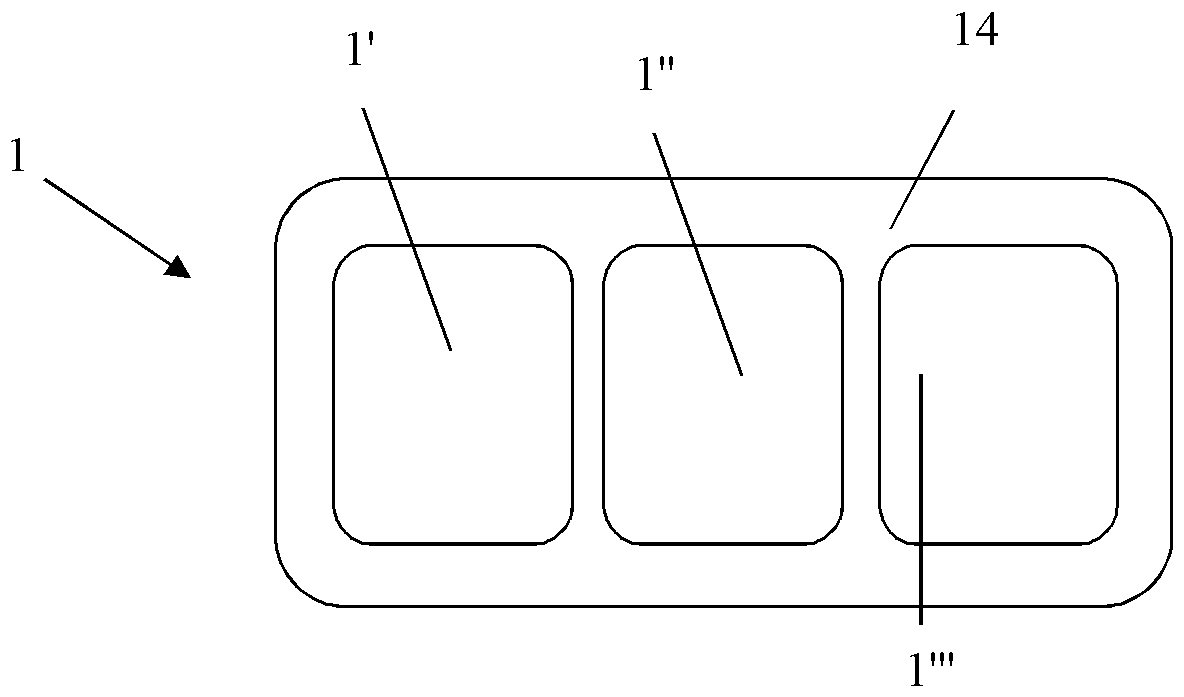

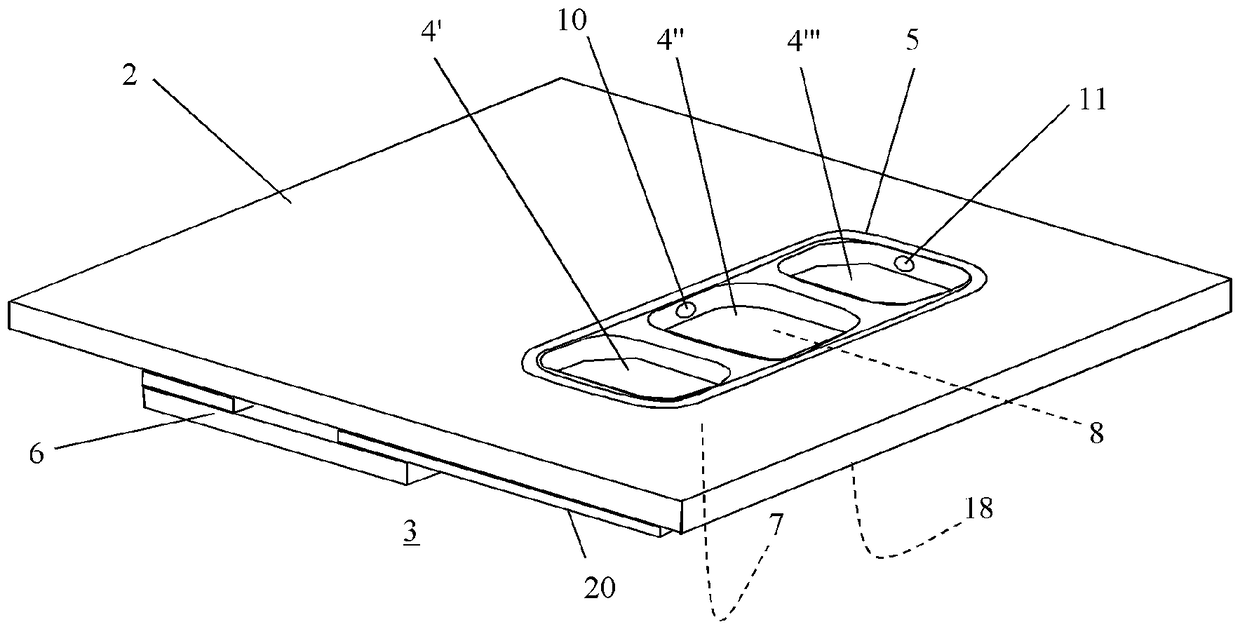

[0056] In general, the present invention relates to apparatus and methods for cleaning and / or replacing laser windows of process chambers. More particularly, the present invention relates to a sealing plate which, in combination with an inner sealing ring, can form a lock chamber within a process chamber and in which an atmosphere can be formed separately from the atmosphere in the process chamber. The lock chamber is formed within the processing chamber around an opening in the outer wall fitted with a laser window. The invention relates in particular to the application of layer-by-layer manufacturing of 3D objects in a process chamber using processes and lasers known per se to the skilled person.

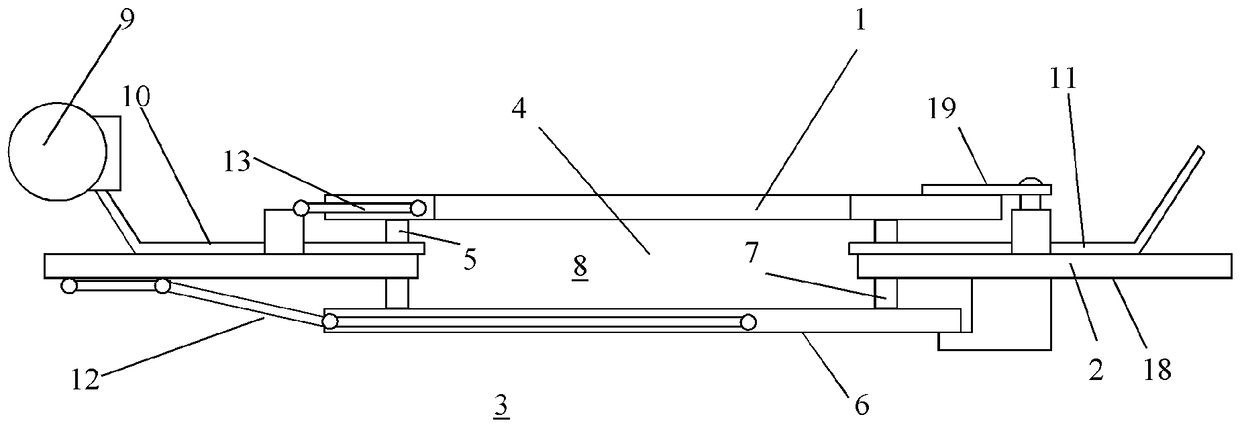

[0057] Figures 1 to 3 A diagram showing an embodiment of a device according to the invention.

[0058] During the execution of the process, if a laser is used to fabricate a 3D object layer by layer, the treatment chamber 3 is completely closed in order to generate the desired ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com