Low stress clamping method for lap joint of part by facing boss

A low-stress, clamping technology, applied in the field of parts compression, can solve the problems of large clamping stress, accumulation of clamping stress, and low processing quality of parts, and achieve the effect of reducing clamping stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present invention is a low-stress clamping method for overlapping parts facing bosses, comprising the following steps:

[0031] Step 1. According to the structural characteristics of the part, select the long direction of the part as the main direction of clamping;

[0032] Step 2. Select the leftmost boss in the main direction as the clamping starting point;

[0033] Step 3. Select the boss closest to the starting point of clamping as the clamping point;

[0034] Step 4. Calculate the distance between the boss whose clamping sequence is not determined and the clamping start point and the clamping point, and use the boss with the smallest sum of distances from the clamping point and the initial clamping point as the clamping point;

[0035] Step 5. Select a new clamping starting point on the other side of the part corresponding to the clamping point. The starting point is the first boss on the other side of the part in the clamping direction whose clamping sequence...

Embodiment 2

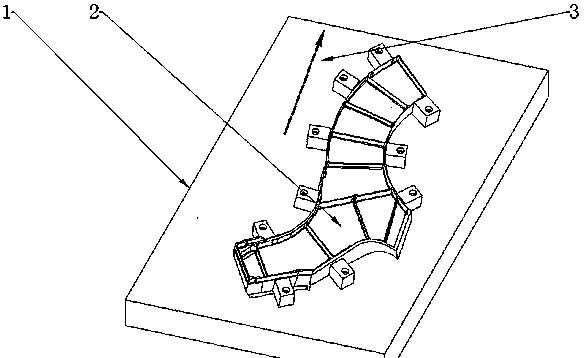

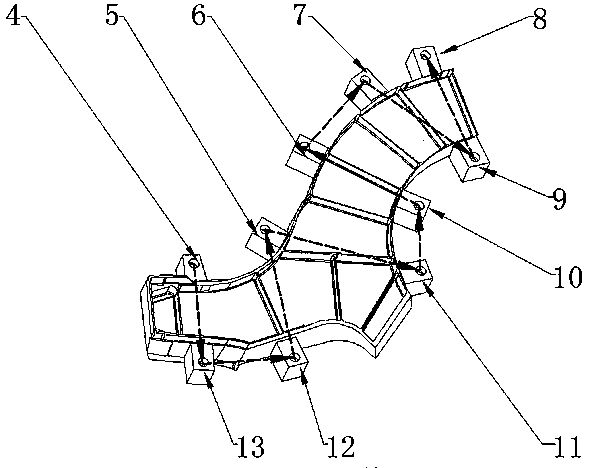

[0038] like figure 1 , figure 2 The part 2 shown is a grooved part, and the part is fixed by adding process bosses. Considering its structural characteristics and processing scheme, 10 bosses are set for compaction, and the positions of the bosses are symmetrically distributed. The size of the bosses is determined according to the Determined by part thickness and length.

[0039] Establish the clamping sequence as follows:

[0040] Step 1. Take the long direction 3 of the part as the main direction of part clamping, and select the boss 4 located on the leftmost side of the main direction as the starting point A of clamping 0 ;

[0041] Step 2. Calculate the boss 5-13 and the starting point A of the clamping in sequence 0 The distance will be with the clamping starting point A 0 The boss 13 with the smallest distance is used as the clamping point A 1 , to establish the initial clamping order sequence O 1 ={4 , 13};

[0042] Step 3. Calculate the distances between all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com