A Diode Pumped Laser Module Crystal Bar

A technology for pumping lasers and crystal rods, which is applied in the direction of lasers, semiconductor lasers, laser components, etc., can solve the problems of uneven heat conduction of crystal rods, difficulty in controlling the clamping force of crystal rods, and high average power, so as to reduce the coaxiality Processing accuracy requirements, improving the uniformity of the output spot, and reducing the effect of clamping stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

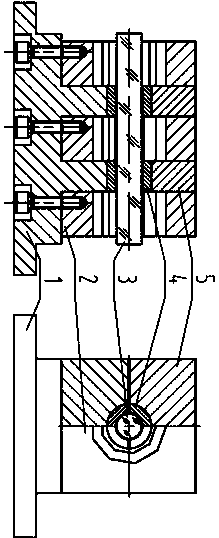

[0034] As shown in the figure, the packaging structure of the crystal rod of the diode-pumped laser module used in the present invention is completely different from the existing packaging structure. First, considering the heat conduction problem of the crystal rod, in order to solve the problem of uniform pressure on the entire surface of the crystal rod, the rod All the heat on the body is transferred out, so the surface around the crystal rod needs to be in contact with the heat-conducting structure. Therefore the present invention has designed a rod heat sink with circular hole, and crystal rod is passed through the circular hole of rod heat sink, so just makes rod heat sink and crystal rod can contact in an all-round way, for the contact section of crystal side, on the crystal rod The hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com